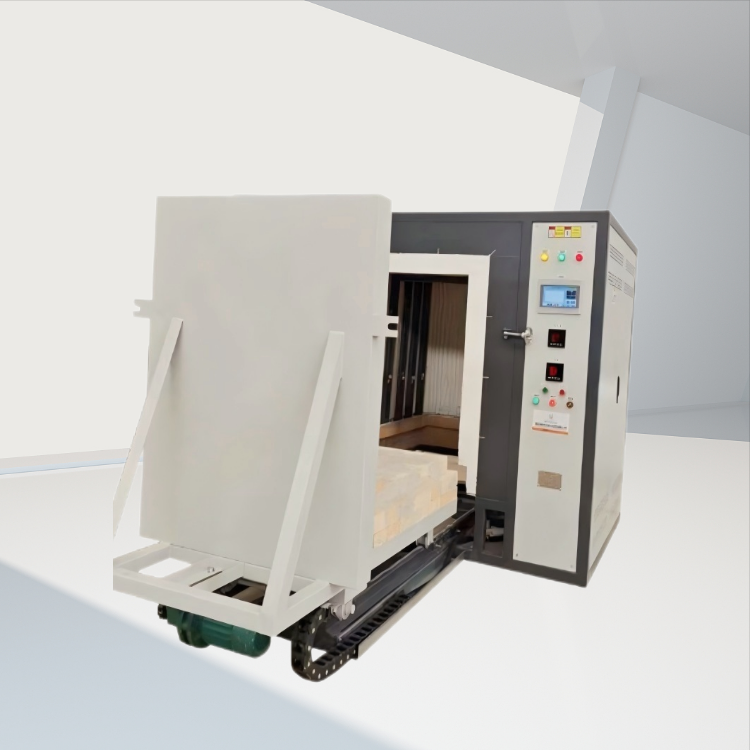

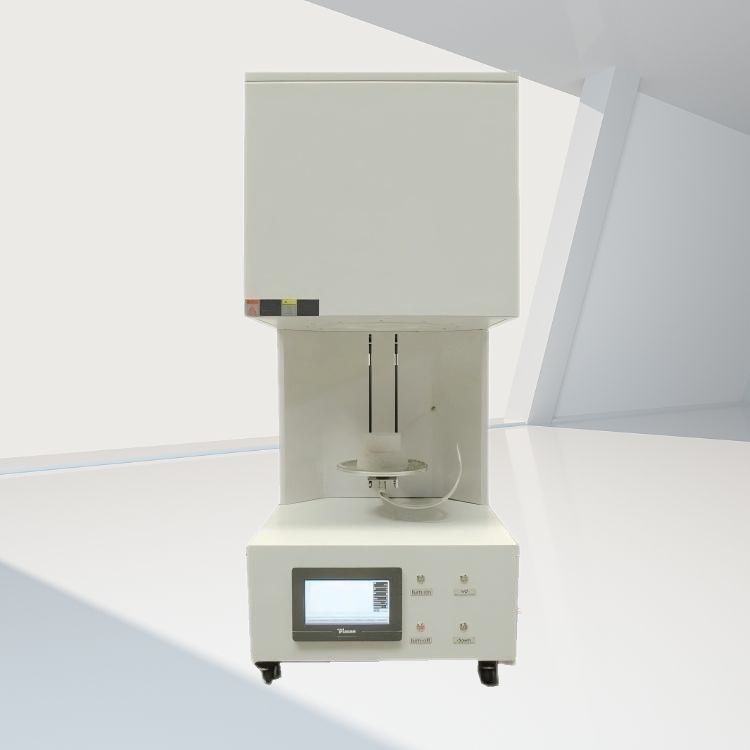

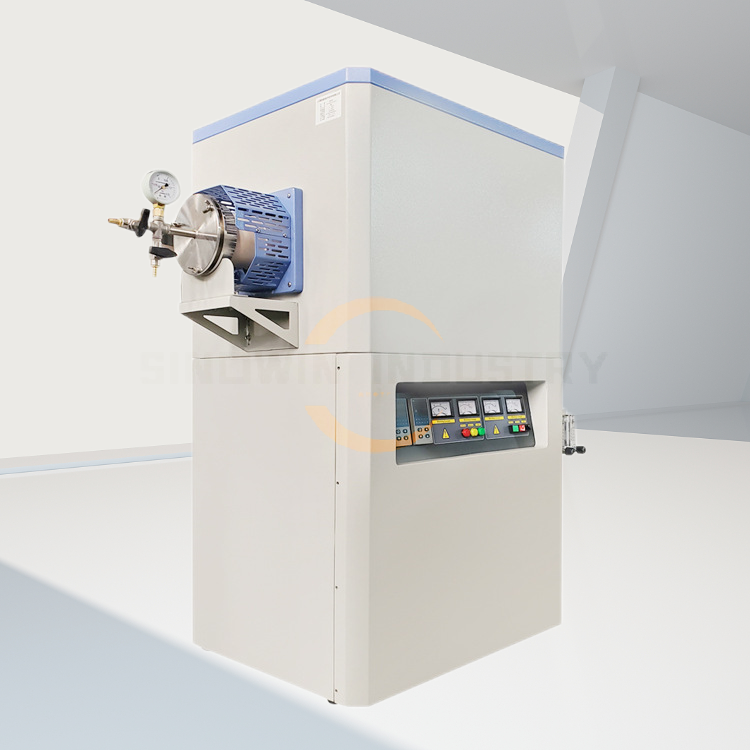

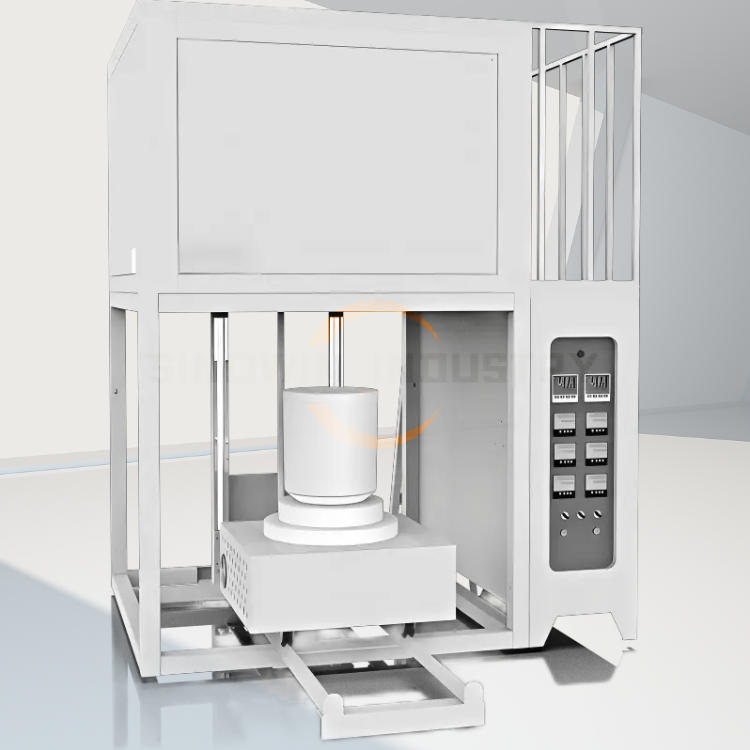

Product Description: 1200C Bell Type Chamber Bottom Loading Furnace for Heat Treatment

The 1200C Bell Type Chamber Bottom Loading Furnace utilizes a unique design that allows materials to be loaded from the bottom, facilitating easy access and ensuring optimal heating efficiency. The hooded construction enhances temperature uniformity and minimizes energy loss, allowing for consistent results every time.

How does it work?

The functionality of the 1200C Bell Type Chamber Bottom Loading Furnace is straightforward yet effective. Once materials are loaded into the furnace, the advanced heating elements distribute heat evenly throughout the chamber. The intuitive control panel allows users to set precise temperature and time settings, ensuring that each firing process meets specific requirements. Additionally, the furnace is equipped with robust insulation materials that enhance safety and energy efficiency during operation.

What are its applications of the 1200C Bell Type Chamber Bottom Loading Furnace for Heat Treatment?

This 1200C Bell Type Chamber Bottom Loading Furnace is suitable for a variety of applications, including ceramic firing, metal annealing, glass melting, and sintering of advanced materials. Its high-temperature capability and reliable performance make it an essential tool for laboratories, universities, and production facilities looking to achieve superior results in their thermal processing tasks.

Technical Parameter of the 1200C Bell Type Chamber Bottom Loading Furnace for Heat Treatment

1200C Bell Type Chamber Bottom Loading Furnace for Heat Treatment |

|

| Main Specifications: | |

| Inside Chamber Size | Dia150H200mm support customized |

| Standard Working Temperature | 1100oC ( continuous ) |

| Maximum Working Temperature | 1200oC ( < 3 hrs) |

| Temperature Control | 51 steps programmable and PID automatic control |

| Heating Rate | 0~ 40.C/ min (suggestion: =< 20.C ) |

| Temperature Accuracy | +/- 1 .C |

| Furnace structure | Double shell with fan cooling |

| Heating Element | Kanthal resistance wire |

| Thermocouples | K type |

| Working Voltage | AC 220V Single Phases 60/50 Hz (or according to your requirement) |

| Max. Power | 4 KW |

| Outside Size | 550 x 540 x 820 mm |

| Net Weight | 60 Kg |

| SW series box furnaces are the most cost effective bench-top high temperature muffle furnace. The furnace consists of high quality alumina fiber brick and MoSi2 heating elements with special design, and furnace temperature is controlled by high precision SCR (Silicon Controlled Rectifier) digital controller with accuracy +/-1 deg oC and 30 segments programmable. It is an ideal tool for materials annealing and Sintering in your research laboratory. | |

| Standard package included with the furnace | |

| Part description | Quantity |

| High Temperature Muffle Furnace | 1 pc |

| K type Thermocouples | 1 pc |

| Al2O3 Sample Plate | 20usd/ea |

| Al2O3 Furnace Door Block | 1 pc |

| Crucible Clip | 1 pc |

| Thermal gloves | 1 pair |

| Operation manual | 1 pc |

| Model | Chamber size(WxHxDmm) |

| SW-1200BL | 120x120x130mm or dia120H150mm |

| SW-1200BL | 150x150x150mm or dia150H200mm |

| SW-1200BL | 200x200x200mm or dia200H200mm |

| SW-1200BL | 200x200x300mm or dia200H300mm |

| SW-1200BL | 250x250x300mm or dia250H300mm |

| SW-1200BL | 300x300x400mm or dia300H400mm |

| SW-1200BL | 450x450x500mm or dia450H500mm |

Whether you’re in the manufacturing sector or a research facility, our 1200C Bell Type Chamber Bottom Loading Furnace is an indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with user-friendly operation. Donot hesitate to Contact us at once for any further information ,we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Technical Parameter of the 1200C Bell Type Chamber Bottom Loading Furnace for Heat Treatment

1200C Bell Type Chamber Bottom Loading Furnace for Heat Treatment |

|

| Main Specifications: | |

| Inside Chamber Size | Dia150H200mm support customized |

| Standard Working Temperature | 1100oC ( continuous ) |

| Maximum Working Temperature | 1200oC ( < 3 hrs) |

| Temperature Control | 51 steps programmable and PID automatic control |

| Heating Rate | 0~ 40.C/ min (suggestion: =< 20.C ) |

| Temperature Accuracy | +/- 1 .C |

| Furnace structure | Double shell with fan cooling |

| Heating Element | Kanthal resistance wire |

| Thermocouples | K type |

| Working Voltage | AC 220V Single Phases 60/50 Hz (or according to your requirement) |

| Max. Power | 4 KW |

| Outside Size | 550 x 540 x 820 mm |

| Net Weight | 60 Kg |

| SW series box furnaces are the most cost effective bench-top high temperature muffle furnace. The furnace consists of high quality alumina fiber brick and MoSi2 heating elements with special design, and furnace temperature is controlled by high precision SCR (Silicon Controlled Rectifier) digital controller with accuracy +/-1 deg oC and 30 segments programmable. It is an ideal tool for materials annealing and Sintering in your research laboratory. | |

| Standard package included with the furnace | |

| Part description | Quantity |

| High Temperature Muffle Furnace | 1 pc |

| K type Thermocouples | 1 pc |

| Al2O3 Sample Plate | 20usd/ea |

| Al2O3 Furnace Door Block | 1 pc |

| Crucible Clip | 1 pc |

| Thermal gloves | 1 pair |

| Operation manual | 1 pc |

| Model | Chamber size(WxHxDmm) |

| SW-1200BL | 120x120x130mm or dia120H150mm |

| SW-1200BL | 150x150x150mm or dia150H200mm |

| SW-1200BL | 200x200x200mm or dia200H200mm |

| SW-1200BL | 200x200x300mm or dia200H300mm |

| SW-1200BL | 250x250x300mm or dia250H300mm |

| SW-1200BL | 300x300x400mm or dia300H400mm |

| SW-1200BL | 450x450x500mm or dia450H500mm |