Description of the 1400°C double-zone RTP&Sliding Tube furnace

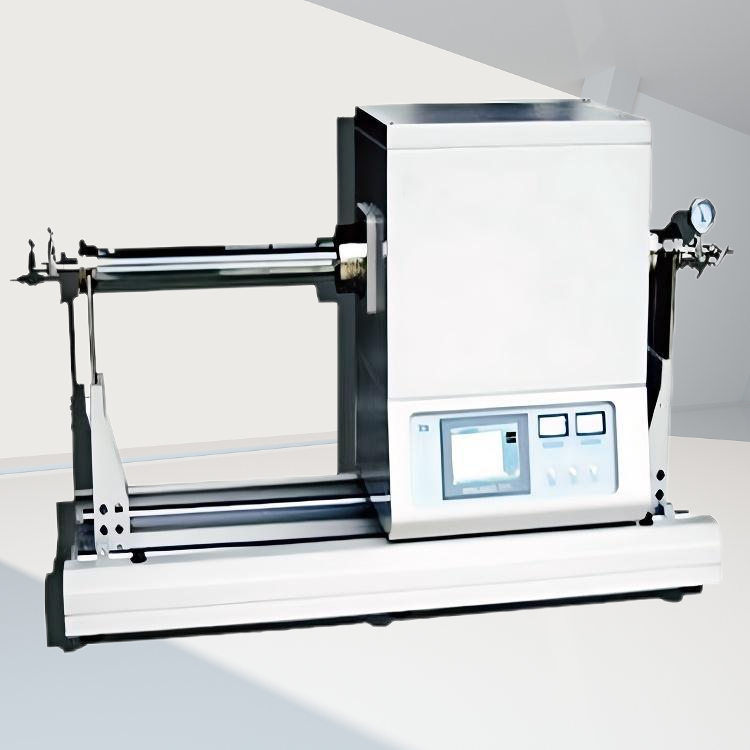

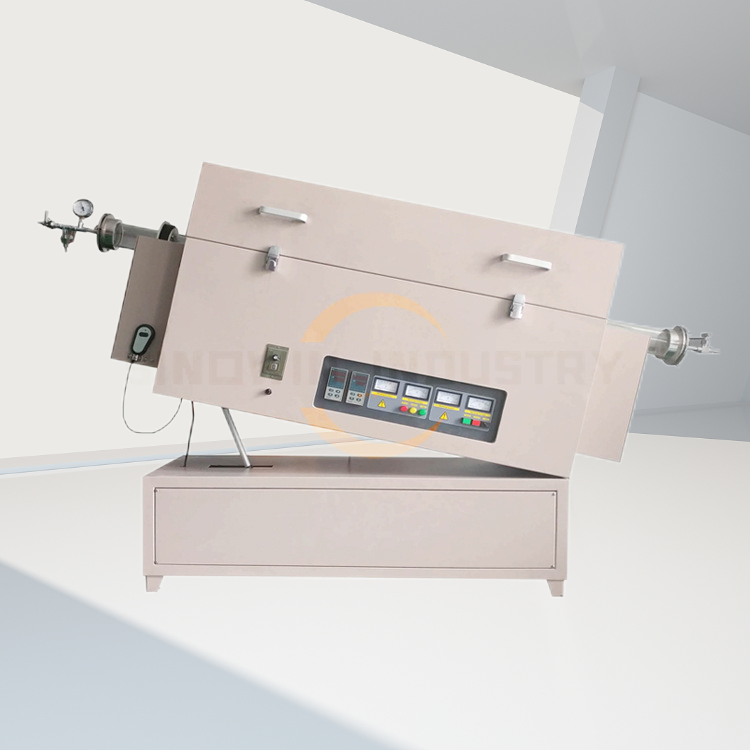

The 1400°C double-zone RTP & Sliding Tube furnace is designed and produced for specialized graphene growth applications. This advanced furnace is ideal for CVD experiments, meeting the demands for rapid heating and cooling processes.

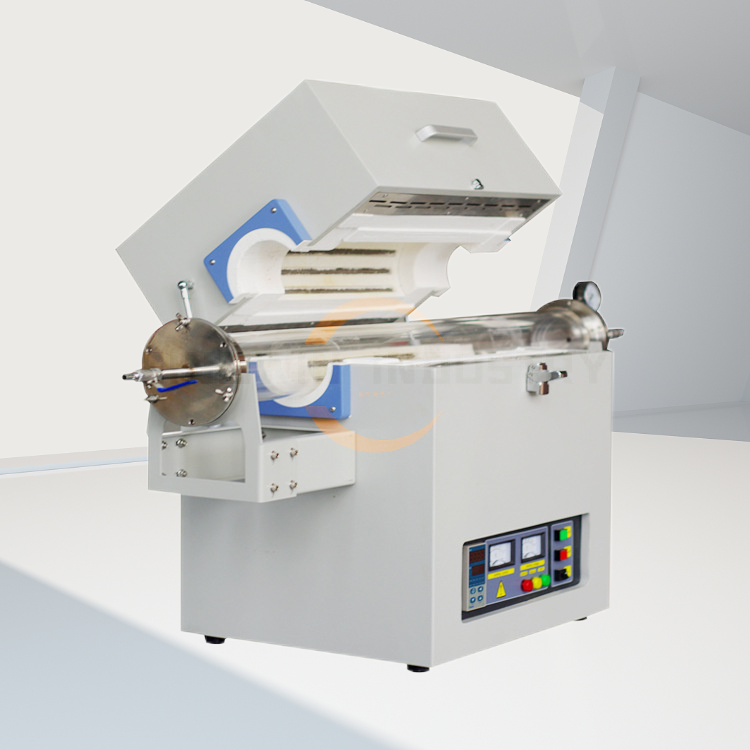

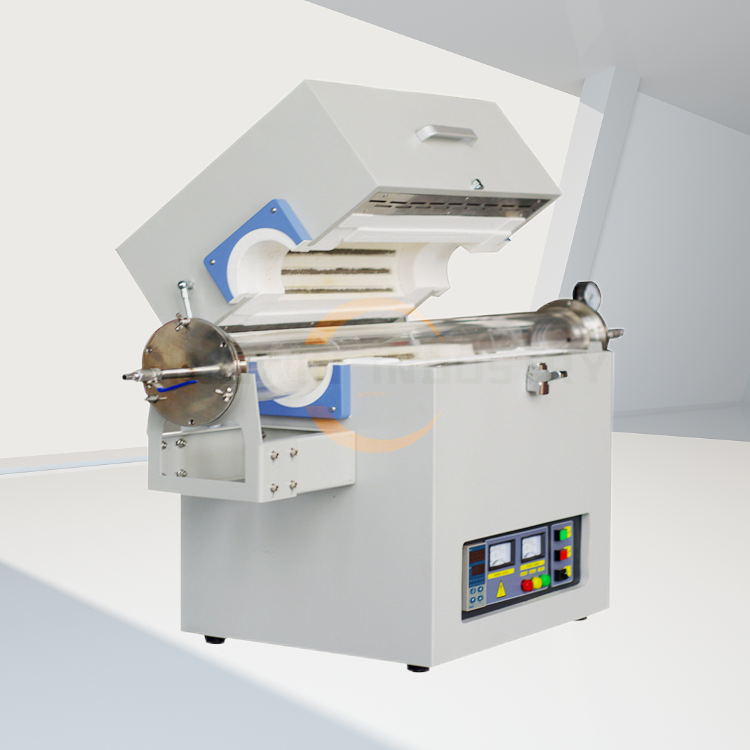

The furnace features an open-type tubular design, strategically engineered with a straight-bottom rail that facilitates easy access and optimal space for the test sample post-experiment. This configuration ensures the achievement of rapid cooling requirements without compromising the integrity of your work.

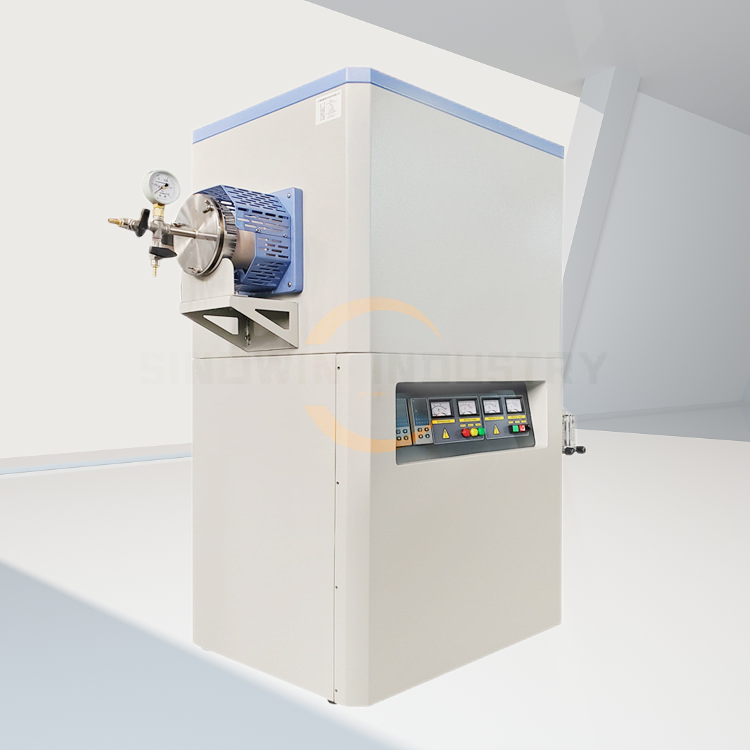

Equipped with imported silicon carbide rods as heating elements, the 1400 Vacuum Tube Furnace delivers unparalleled performance. The innovative double-shell structure, coupled with an intelligent program temperature control system, allows for precise monitoring and adjustment. The phase-shift trigger and SCR control enhance operational efficiency while ensuring safety and reliability throughout the heating process.

The furnace chamber is lined with high-quality poly-crystalline alumina fiber material, promoting effective insulation and durability. An integrated air cooling system between the double furnace shells ensures rapid heating and cooling, making this unit suitable for various experimental needs. Furthermore, the vacuum device enables operation in protective gas or vacuum settings, adding versatility to your processes.

Main function and features:

- Adopted KF quick flange sealing, only need a clamp flange the connection can be done. It is very convenient to put and take the specimen. Avoiding bolt leakage by artificial operation and reduced the ratio of heating tube damaging which caused by installation flanges;

- Furnace chamber adopted imported alumina poly-crystalline fibers, effective insulation and energy saving. Imported silicon carbide as heating element, greatly improving its service life, high density imported alumina tube, durable use and not easy break;

- Reserved vacuum, gas road fast interface, could working with our vacuum system or mixed gas system;

- Reserved 485 convert interface, can be connected with PC through software. It has remote control, real time tracking, history recorder, and output report function. And can be installed the paperless recorder for data storage and output;

- Built – in Thermocouples, real-time monitoring the temperature of the heated material;

- Optional with the observation window flange, real-time observation of the sintered material conditions;

- Over-temperature alarm and power failure, leakage protection, safe and reliable operation.

Parameters of the 1400°C double-zone RTP&Sliding Tube furnace

| Parameters of the 1400°C double-zone RTP&Sliding Tube furnace | ||

| Main Specifications: | ||

| Inside Chamber Size | dia60x300mm(diameter2.5″ x 12″) | |

| Standard Working Temperature | 1300oC ( continuous ) | |

| Maximum Working Temperature | 1450oC ( < 3 hrs) | |

| Furnace chamber | slide Tube Furnace | |

| Max. vacuum | l0.1MPa | |

| Temperature Control | 30 steps programmable and PID automatic control | |

| Heating Rate | 0~ 20.C/ min (suggestion: =< 10.C ) | |

| Temperature Accuracy | l/- 1 .C | |

| Furnace structure | double shell with fan cooling | |

| Heating Element | SiC heating elements | |

| Thermocouples | S type | |

| Working Voltage | AC 220V Single Phase 60/50 Hz (or according to your requirement) | |

| Max. Power | 5KW | |

| Net Weight | 90kg | |

| Detailed Description | ||

| The 1400 double-zone RTP&Sliding tube furnace is a precision bench-top furnace using quality ceramic SiC rod as heating elements. It is widely used for materials or chemical lab to sinter all types of new materials samples under vacuum or other gases condition. It is controlled by high precision SCR ( Silicon Controlled Rectifier) digital controller with accuracy +/-1.C and 30 segments programmable up to 1400.C. | ||

| Standard package included with the furnace | ||

| Part description | Quantity | |

| Tube plug | 4pcs | |

| quartz tube | 1pc | |

| vacuum pump | 1pc | |

| Sealing flange | 1set | |

| vacuum gauge | 1pc | |

| Thermal couple | 1 pc | |

| Stainless steel hook | 1 pc | |

| Thermal gloves | 1 pair | |

| Operation manual | 1 pc | |

| Standard Sizes: | ||

| Model | Chamber size (Outer diameter of furnace tube x heating length) | Max. Temperature |

| SWTF-1400 | 25×300/400/600/800mm | 1450.C |

| SWTF-1400 | 45×300/400/600/800mm | 1450.C |

| SWTF-1400 | 60×300/400/600/800mm | 1450.C |

| SWTF-1400 | 80×300/400/600/800mm | 1450.C |

| SWTF-1400 | 100×300/400/600/800mm | 1450.C |

| SWTF-1400 | 120×300/400/600/800mm | 1450.C |

The 1400°C double-zone RTP & Sliding Tube furnace produced by nanyang sinowin industry is an essential tool for researchers and manufacturers seeking high-performance equipment for graphene growth and advanced CVD experiments. Whether you are conducting in-depth research or scaling up production, our furnace promises to meet and exceed your expectations in efficiency and performance.

Please feel free to consult for any additional questions or specifics related to your requirements for our 1400°C double-zone RTP&Sliding Tube furnace !and Nanyang sinowin industry co.ltd are not only a lab and industrial furnace supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Parameters of the 1400°C double-zone RTP&Sliding Tube furnace

| Parameters of the 1400°C double-zone RTP&Sliding Tube furnace | ||

| Main Specifications: | ||

| Inside Chamber Size | dia60x300mm(diameter2.5″ x 12″) | |

| Standard Working Temperature | 1300oC ( continuous ) | |

| Maximum Working Temperature | 1450oC ( < 3 hrs) | |

| Furnace chamber | slide Tube Furnace | |

| Max. vacuum | l0.1MPa | |

| Temperature Control | 30 steps programmable and PID automatic control | |

| Heating Rate | 0~ 20.C/ min (suggestion: =< 10.C ) | |

| Temperature Accuracy | l/- 1 .C | |

| Furnace structure | double shell with fan cooling | |

| Heating Element | SiC heating elements | |

| Thermocouples | S type | |

| Working Voltage | AC 220V Single Phase 60/50 Hz (or according to your requirement) | |

| Max. Power | 5KW | |

| Net Weight | 90kg | |

| Detailed Description | ||

| The 1400 double-zone RTP&Sliding tube furnace is a precision bench-top furnace using quality ceramic SiC rod as heating elements. It is widely used for materials or chemical lab to sinter all types of new materials samples under vacuum or other gases condition. It is controlled by high precision SCR ( Silicon Controlled Rectifier) digital controller with accuracy +/-1.C and 30 segments programmable up to 1400.C. | ||

| Standard package included with the furnace | ||

| Part description | Quantity | |

| Tube plug | 4pcs | |

| quartz tube | 1pc | |

| vacuum pump | 1pc | |

| Sealing flange | 1set | |

| vacuum gauge | 1pc | |

| Thermal couple | 1 pc | |

| Stainless steel hook | 1 pc | |

| Thermal gloves | 1 pair | |

| Operation manual | 1 pc | |

| Standard Sizes: | ||

| Model | Chamber size (Outer diameter of furnace tube x heating length) | Max. Temperature |

| SWTF-1400 | 25×300/400/600/800mm | 1450.C |

| SWTF-1400 | 45×300/400/600/800mm | 1450.C |

| SWTF-1400 | 60×300/400/600/800mm | 1450.C |

| SWTF-1400 | 80×300/400/600/800mm | 1450.C |

| SWTF-1400 | 100×300/400/600/800mm | 1450.C |

| SWTF-1400 | 120×300/400/600/800mm | 1450.C |