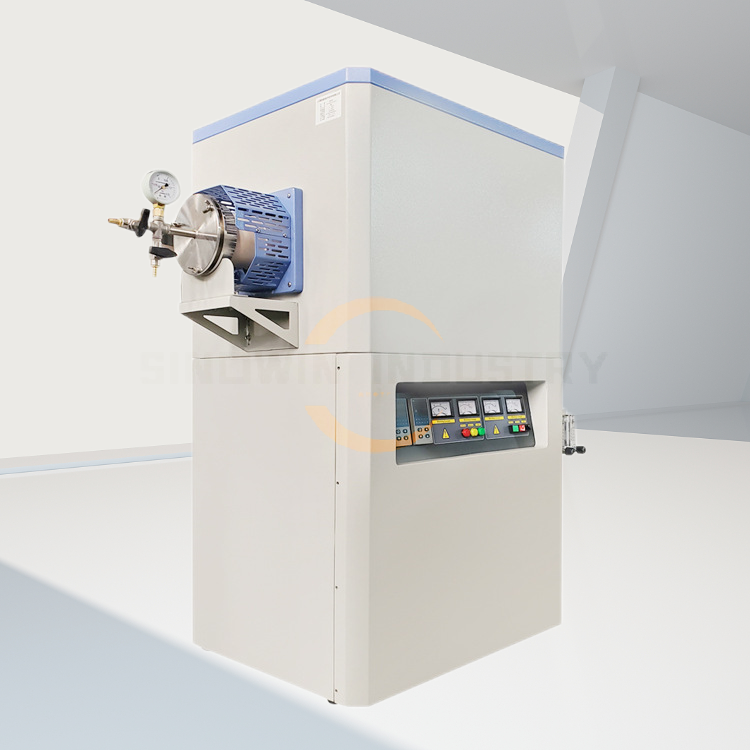

Product Description: 1700 Degree Bottom Loading Elevator Furnace

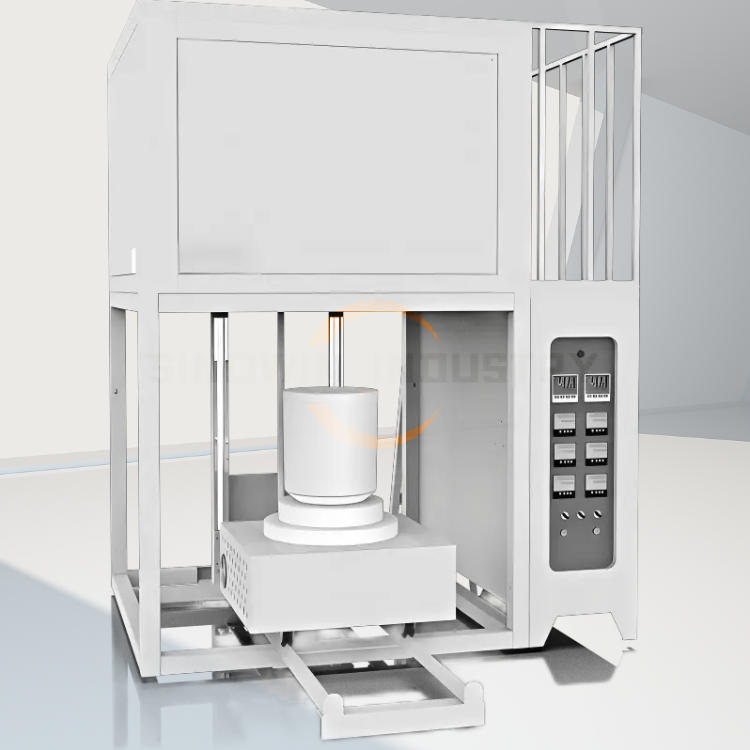

The 1700 Degree Bottom Loading Elevator Furnace supplied by nanyang sinowin industry is an advanced thermal processing solution designed for high-temperature applications in various industries such as sintering, ceramics, metal processing, and other applications requiring precise temperature control and exceptional thermal efficiency.Produced by nanyang sinowin industry ,the furnace features a unique bottom-loading design, allowing for easy access and loading of materials from the bottom of the unit. This design not only promotes efficient space utilization but also minimizes disturbances to the heating chamber, ensuring uniform heat distribution and optimal performance.

How Does It Work?

This furnace utilizes high-quality insulation materials and a robust heating element to achieve and maintain high temperatures of 1700 degrees Celsius. The bottom-loading mechanism allows users to seamlessly load and unload materials without compromising the thermal integrity of the chamber. The furnace is equipped with advanced digital controls that provide precise temperature regulation and monitoring, ensuring that your heating processes are both reliable and efficient.

Applications of the 1700 Degree Bottom Loading Elevator Furnace

The versatility of the 1700 Degree Bottom Loading Elevator Furnace makes it suitable for a wide range of applications, including:

- Sintering of advanced ceramics and metal parts

- Heat treatment processes for alloys and composites

- Laboratory research and development in materials science

- Production of high-performance components in aerospace and automotive industries

Elevate your heating capabilities with the 1700 Degree Bottom Loading Elevator Furnace – where high temperature meets innovative design for unparalleled performance.

Technical Parameter of the 1700 Degree Bottom Loading Elevator Furnace

1700 Degree Bottom Loading Elevator Furnace |

|

| Main Specifications: | |

| Inside Chamber Size | 120/150MM Dia/H |

| Standard Working Temperature | 1600oC ( continuous ) |

| Maximum Working Temperature | 1700oC ( < 3 hrs) |

| Temperature Control | 30 steps programmable and PID automatic control |

| Heating Rate | 0~ 40.C/ min (suggestion: =< 20.C ) |

| Temperature Accuracy | +/- 1 .C |

| Heating Element | MoSi2 heating elements |

| Working Voltage | AC 220V Three Phases 60/50 Hz (or according to your requirement) |

| Max. Power | 4KW |

| Outside Size | 500 x 600 x 1200 mm |

| Net Weight | 200 Kg |

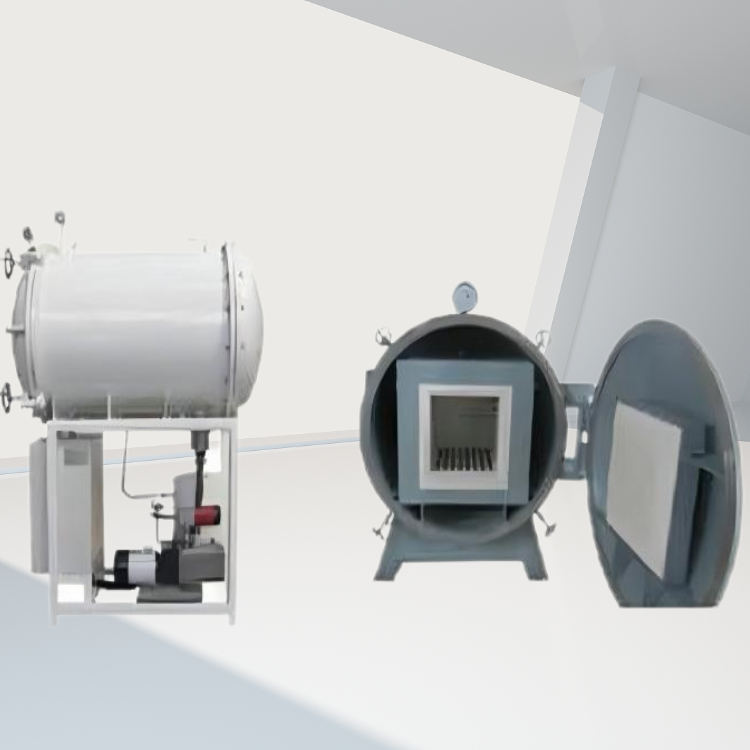

| SW-1700BL The single zone, high temperature, bottom loading furnace is capable of operating at temperatures up to 1650oC in air. The furnace utilizes 1800oC molydisilicide heating elements positioned on three sides of the internal chamber. The furnace utilizes an energy efficient insulation package consisting of graded ceramic-fiber, high temperature insulation. It is an ideal tool for materials annealing and sintering. | |

| Model | Chamber size(WxHxDmm) |

| SW-1700BL | 120x120x130mm or dia120H150mm |

| SW-1700BL | 150x150x150mm or dia150H200mm |

| SW-1700BL | 200x200x200mm or dia200H200mm |

| SW-1700BL | 200x200x300mm or dia200H300mm |

| SW-1700BL | 250x250x300mm or dia250H300mm |

| SW-1700BL | 300x300x400mm or dia300H400mm |

| SW-1700BL | 450x450x500mm or dia450H500mm |

With the 1700 Degree Bottom Loading Elevator Furnace, you can achieve superior results with enhanced productivity and reliability. Whether you are in a manufacturing setting or a research laboratory, this furnace is the perfect addition to your thermal processing equipment lineup.

Donot hesitate to Contact us at once for more information ,NanYang Sinowin Industry are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Technical Parameter of the 1700 Degree Bottom Loading Elevator Furnace

1700 Degree Bottom Loading Elevator Furnace |

|

| Main Specifications: | |

| Inside Chamber Size | 120/150MM Dia/H |

| Standard Working Temperature | 1600oC ( continuous ) |

| Maximum Working Temperature | 1700oC ( < 3 hrs) |

| Temperature Control | 30 steps programmable and PID automatic control |

| Heating Rate | 0~ 40.C/ min (suggestion: =< 20.C ) |

| Temperature Accuracy | +/- 1 .C |

| Heating Element | MoSi2 heating elements |

| Working Voltage | AC 220V Three Phases 60/50 Hz (or according to your requirement) |

| Max. Power | 4KW |

| Outside Size | 500 x 600 x 1200 mm |

| Net Weight | 200 Kg |

| SW-1700BL The single zone, high temperature, bottom loading furnace is capable of operating at temperatures up to 1650oC in air. The furnace utilizes 1800oC molydisilicide heating elements positioned on three sides of the internal chamber. The furnace utilizes an energy efficient insulation package consisting of graded ceramic-fiber, high temperature insulation. It is an ideal tool for materials annealing and sintering. | |

| Model | Chamber size(WxHxDmm) |

| SW-1700BL | 120x120x130mm or dia120H150mm |

| SW-1700BL | 150x150x150mm or dia150H200mm |

| SW-1700BL | 200x200x200mm or dia200H200mm |

| SW-1700BL | 200x200x300mm or dia200H300mm |

| SW-1700BL | 250x250x300mm or dia250H300mm |

| SW-1700BL | 300x300x400mm or dia300H400mm |

| SW-1700BL | 450x450x500mm or dia450H500mm |