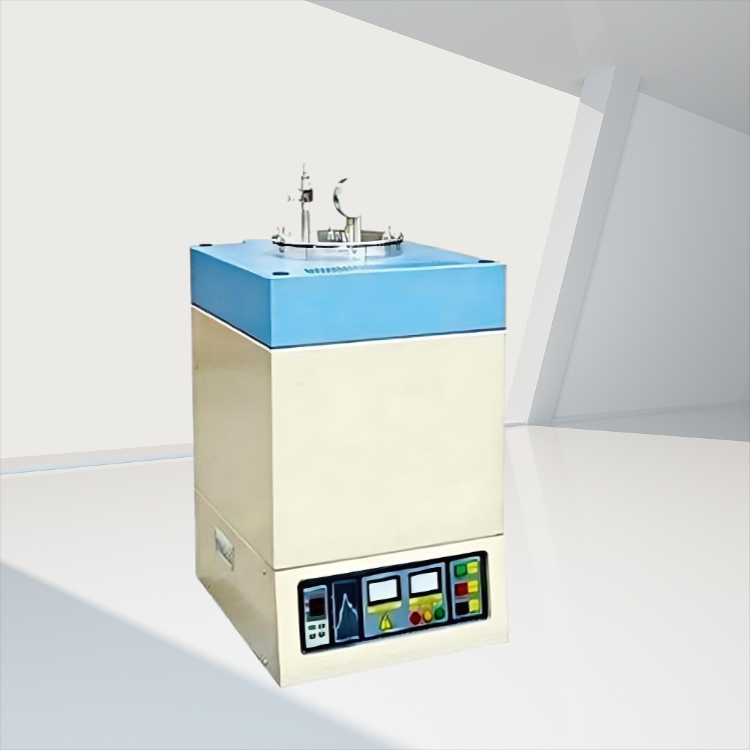

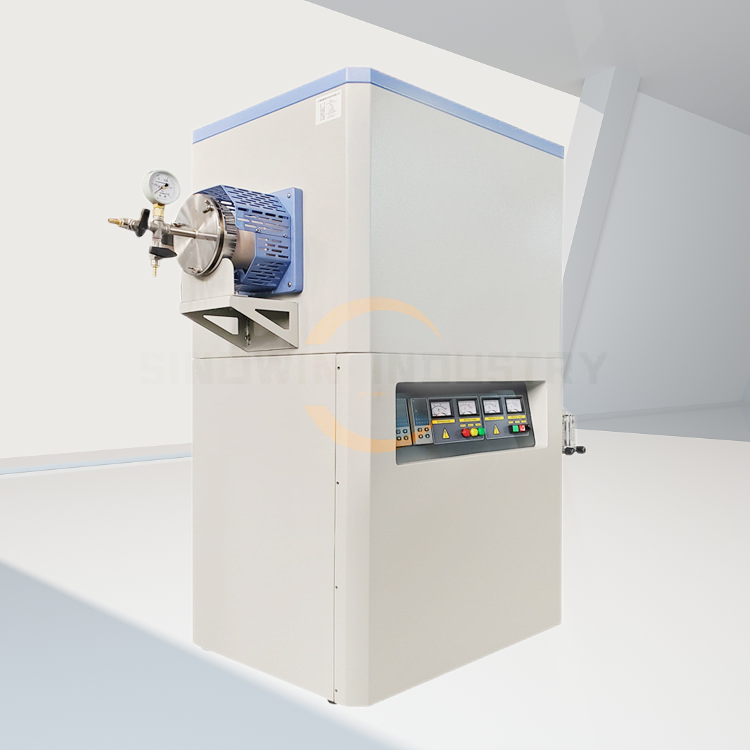

Product Description: 1700 Degree Top-Loading Vacuum Furnace

The 1700 Degree Top-Loading Vacuum Furnace is designed and produced by nanyang sinowin industry to meet the rigorous demands of industries requiring high-temperature sintering, annealing, and other critical thermal applications. The furnace features a robust construction that ensures durability and reliability while maintaining a uniform temperature distribution for optimal results. Its innovative top-loading design simplifies loading and unloading processes, offering convenient access and maximizing productivity. it is Ideal for a variety of materials, including ceramics, metals, and composites, the 1700 Degree Top-Loading Vacuum Furnace caters to the specific needs of advanced manufacturing and aerospace applications.

Harnessing the power of vacuum technology, this furnace significantly reduces oxidation and contamination during heat treatment, leading to improved material properties and superior product quality.

Technical Parameters of the 1700 Degree Top-Loading Vacuum Furnace

1700 Degree Top-Loading Vacuum Furnace |

|

| Main Specifications: | |

| Inside Chamber Size | Dia240 x 220mm |

| Standard Working Temperature | 1600oC ( continuous ) |

| Maximum Working Temperature | 1700oC ( < 3 hrs) |

| Vacuum Flange | Stainless steel with double hi-temperature silicone O-rings ( <300oC) Ball valve and vacuum gauge is installed for immediate use

Vacuum pressure up to 10Pa by mechanical pump One porous ceramic disk is included. Must put the refractory disk in front flange to avoid flange over-heated |

| Temperature Control | 30 steps programmable and PID automatic control |

| Heating Rate | 0~ 40.C/ min (suggestion: =< 20.C ) |

| Temperature Accuracy | +/- 1 .C |

| Furnace structure | Double shell with fan cooling |

| Heating Element | High quality Mois2 heater M1800 |

| Thermocouples | B type |

| Working Voltage | AC 220V single Phases 60/50 Hz (or according to your requirement) |

| Max. Power | 6KW |

| Outside Size | 550 x640 x820 mm |

| Net Weight | 160kg |

| Detailed Description | |

| High quality High quality SiC heater as heating element and can be heated up to 1700oC .

Stainless steel vacuum flange with one two ball valves and vacuum gauge is included for immediate use. Built in precision digital temperature controller is 30 segments programmable to control heating rate, cooling rate and dwell time All accessories are included for immediate use One pcs refractory disk which shall be put top of inside quartz liner to protect stainless steel from heat damage. |

|

| Standard package included with the furnace | |

| Part description | Quantity |

| High Temperature Muffle Furnace | 1 pc |

| Heating Element, spare parts | 2 pcs |

| B type Thermocouples | 1 pc |

| Al2O3 Sample Plate | 1 pc |

| Al2O3 Furnace Door Block | 1 pc |

| Crucible Clip | 1 pc |

| Thermal gloves | 1 pair |

| Operation manual | 1 pc |

| Standard Sizes: | |

| Model | Chamber size (WXHXDmm OR DIA/Hmm) |

| SW-1700VCF | 120x120x130mm or dia120H150mm |

| SW-1700VCF | 150x150x150mm or dia150H200mm |

| SW-1700VCF | 200x200x200mm or dia200H200mm |

| SW-1700VCF | 200x200x300mm or dia200H300mm |

| SW-1700VCF | 250x250x300mm or dia250H300mm |

| SW-1700VCF | 300x300x400mm or dia300H400mm |

| SW-1700VCF | 450x450x500mm or dia450H500mm |

For a comprehensive solution that enhances your heat treatment capabilities, trust the 1700 Degree Top-Loading Vacuum Furnace produced by nanyang sinowin industry to deliver exceptional results every time.

Whether you are in the field of ceramics, metals, or semiconductor fabrication, the 1700 Degree Top-Loading Vacuum Furnace produced and supplied by nanyang sinowin industry is your trusted partner in achieving superior results. Invest in quality, efficiency, and unparalleled performance with our advanced furnace solution.

Experience the future of material processing with the 1700 Degree Top-Loading Vacuum Furnace today!

Technical Parameters of the 1700 Degree Top-Loading Vacuum Furnace

1700 Degree Top-Loading Vacuum Furnace |

|

| Main Specifications: | |

| Inside Chamber Size | Dia240 x 220mm |

| Standard Working Temperature | 1600oC ( continuous ) |

| Maximum Working Temperature | 1700oC ( < 3 hrs) |

| Vacuum Flange | Stainless steel with double hi-temperature silicone O-rings ( <300oC) Ball valve and vacuum gauge is installed for immediate use

Vacuum pressure up to 10Pa by mechanical pump One porous ceramic disk is included. Must put the refractory disk in front flange to avoid flange over-heated |

| Temperature Control | 30 steps programmable and PID automatic control |

| Heating Rate | 0~ 40.C/ min (suggestion: =< 20.C ) |

| Temperature Accuracy | +/- 1 .C |

| Furnace structure | Double shell with fan cooling |

| Heating Element | High quality Mois2 heater M1800 |

| Thermocouples | B type |

| Working Voltage | AC 220V single Phases 60/50 Hz (or according to your requirement) |

| Max. Power | 6KW |

| Outside Size | 550 x640 x820 mm |

| Net Weight | 160kg |

| Detailed Description | |

| High quality High quality SiC heater as heating element and can be heated up to 1700oC .

Stainless steel vacuum flange with one two ball valves and vacuum gauge is included for immediate use. Built in precision digital temperature controller is 30 segments programmable to control heating rate, cooling rate and dwell time All accessories are included for immediate use One pcs refractory disk which shall be put top of inside quartz liner to protect stainless steel from heat damage. |

|

| Standard package included with the furnace | |

| Part description | Quantity |

| High Temperature Muffle Furnace | 1 pc |

| Heating Element, spare parts | 2 pcs |

| B type Thermocouples | 1 pc |

| Al2O3 Sample Plate | 1 pc |

| Al2O3 Furnace Door Block | 1 pc |

| Crucible Clip | 1 pc |

| Thermal gloves | 1 pair |

| Operation manual | 1 pc |

| Standard Sizes: | |

| Model | Chamber size (WXHXDmm OR DIA/Hmm) |

| SW-1700VCF | 120x120x130mm or dia120H150mm |

| SW-1700VCF | 150x150x150mm or dia150H200mm |

| SW-1700VCF | 200x200x200mm or dia200H200mm |

| SW-1700VCF | 200x200x300mm or dia200H300mm |

| SW-1700VCF | 250x250x300mm or dia250H300mm |

| SW-1700VCF | 300x300x400mm or dia300H400mm |

| SW-1700VCF | 450x450x500mm or dia450H500mm |