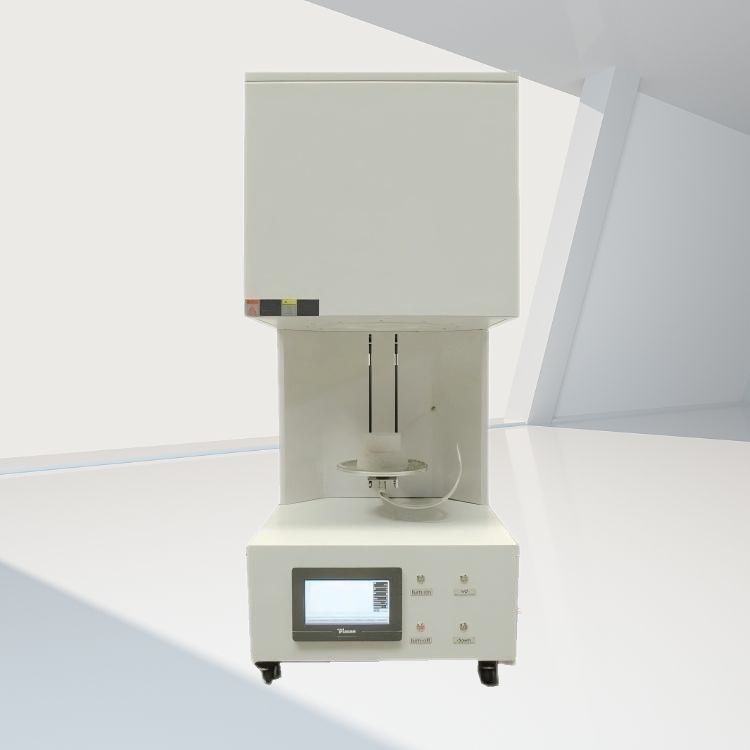

Product Description:

The Vacuum Carbon Tube Furnace, designed for sophisticated processes in the fields of inorganic materials and metals, is an essential tool for sintering and fabricating materials such as ceramic seals, silicon carbide, zirconia, zinc oxide, and alumina in a vacuum or protective atmosphere. Additionally, it excels in the purification treatment of rare earth elements and their oxides, as well as the annealing of sapphire. The Vacuum Carbon Tube Furnace is ideal for universities and research institutions, and one good option for pilot production and medium-scale manufacturing in the heat treatment industry.

Parameter of Vacuum Carbon Tube Furnace

| Working Temp. | 1200℃~2300℃(Customizable) |

| Ultra Temp. | 2400℃ |

| Working Area | Φ120mm~Φ600mm×H100mm~ H500mm(Customizable)。 |

| Heating Method | Graphitic carbon tube(Resistance) |

| Heating Rate | ≤10℃/min |

| Cooling Time | 5hrs |

| Temperature control mode | Programmable and PID auto control

Tungsten sleeve tungsten-rhenium thermocouple — infrared thermometer |

| Temperature uniformity | ≤±10℃ |

| Ultra Vacuum: | 6.7×10-3Pa(Cold state) |

| Charging pressure | ≤ 0.05MPa(Micropositive pressure) |

| Rate of pressure rise | 2 Pa/h |

| Rated voltage | 3phase 380V 50Hz |

Key Features:

- Vertical Structure with Top Discharge: The innovative vertical design facilitates efficient operation and easy material handling.

- Resistive Heating with Long-lasting Graphite Heating Elements: Ensures optimal heating efficiency and durability for extended usage.

- Advanced Temperature Control: Equipped with tungsten-rhenium thermocouple wire, the furnace features two-stage automatic temperature control. Temperatures up to 1500°C are managed by a thermocouple, while temperatures above this range transition to an infrared thermometer to maintain precise temperature regulation.

- Imported Power Regulator: Utilizes a high-quality power regulator from Taiwan, equipped with comprehensive overload, short-circuit, and over-voltage protection mechanisms for enhanced safety.

- Multi-channel Data Acquisition and User Interface: Experience streamlined operation with clear displays of running parameters, making it user-friendly and easy to manage.

- Dual-layer Water Cooling Structure: Facilitates negative pressure vacuum extraction, featuring a vacuum pipeline interface, vacuum destruction valve, and gas filling port.

- Uniform Temperature Distribution: The graphite rod combined heating method promotes excellent temperature uniformity across the heating area.

The Vacuum Carbon Tube Furnace is the pinnacle of performance and reliability, making it an indispensable asset for any laboratory or production environment focused on advancing material science and research. Guaranteed quality and precision with the Vacuum Carbon Tube Furnace supplied by Sinowin Industry to elevate your material processing capabilities.

Technical Parameter of the 2000 degree Vertical Vacuum Carbon Tube Furnace

| Work area | Rate | Max.temp | ultra vacuum |

| Φ90×120㎜ | 25Kw | 2000℃ | 6.67×10-3Pa |

| Φ140×140㎜ | 40Kw | 2000℃ | 6.67×10-3Pa |

| Φ160×160㎜ | 50Kw | 2000℃ | 6.67×10-3Pa |

| Φ220×300㎜ | 85Kw | 2000℃ | 6.67×10-3Pa |

| Φ280×320㎜ | 100Kw | 2000℃ | 6.67×10-3Pa |

| Φ320×320㎜ | 120Kw | 2000℃ | 6.67×10-3Pa |

| Φ320×600㎜ | 210Kw | 2000℃ | 6.67×10-3Pa |

Q&As for vacuum carbon tube furnace product:

Q1: What is a vacuum carbon tube furnace and how does it work?

A1: A vacuum carbon tube furnace is a specialized piece of equipment used for high-temperature applications in a controlled environment. It operates by heating materials in a sealed carbon tube under a vacuum, which eliminates oxidation and contamination. The furnace employs electric resistance heating, allowing it to reach precise temperatures needed for processes such as sintering, carbonization, and material purification.

Q2: What are the advantages of using a vacuum carbon tube furnace?

A2: Utilizing a vacuum carbon tube furnace offers several significant advantages, including enhanced material purity, improved performance characteristics, and the ability to work with delicate materials that may be compromised in open-air environments. The vacuum eliminates oxidation, while the high temperatures enable better sintering and crystallization processes, resulting in superior products.

Q3: How does a vacuum carbon tube furnace improve material properties?

A3: A vacuum carbon tube furnace enhances material properties by minimizing contamination during heating, resulting in higher purity and improved structural integrity. The controlled environment allows for more uniform heating, reducing internal stresses and defects, which ultimately leads to materials that exhibit better mechanical, electrical, and thermal performance.

Q4: What types of materials can be processed in a vacuum carbon tube furnace?

A4: A vacuum carbon tube furnace can process a wide variety of materials, including metals, ceramics, composites, and polymers. It’s especially effective for applications requiring high thermal stability or those that need precise thermal treatments without risk of oxidation or contamination.

Q5: How do I choose the right vacuum carbon tube furnace for my laboratory?

A5: When selecting a vacuum carbon tube furnace for your lab, consider factors such as the required temperature range, material compatibility, chamber size, and vacuum capability. It’s also important to assess your specific application needs and potential future uses, ensuring that the furnace you choose can accommodate them.

Q6: What safety precautions should be taken when using a vacuum carbon tube furnace?

A6: Safety is paramount when operating a vacuum carbon tube furnace. Always wear appropriate personal protective equipment (PPE) such as gloves and goggles. Ensure proper ventilation in the workspace and follow the manufacturer’s guidelines for operation. Regular checks for leaks in the vacuum system are essential, and make sure to familiarize yourself with emergency procedures in case of overheating or power failures.

Q7: What is the typical temperature range of a vacuum carbon tube furnace?

A7: A typical vacuum carbon tube furnace can reach temperatures ranging from 1000°C to 2000°C (1832°F to 3632°F), depending on the model and specifications. This extensive temperature range allows for the processing of a diverse array of materials for various applications across different industries.

Q8: How does a vacuum carbon tube furnace differ from a traditional furnace?

A8: Unlike traditional furnaces that operate in atmospheric conditions and are susceptible to oxidation, a vacuum carbon tube furnace utilizes a vacuum environment, ensuring that materials are heated without exposure to oxygen. This leads to higher purity levels and prevents material degradation, thus producing superior end products.

Q9: Can a vacuum carbon tube furnace be used for commercial purposes?

A9: Absolutely! Vacuum carbon tube furnaces are widely used in commercial settings for various applications such as materials research, metal processing, and high-performance manufacturing. Their ability to produce high-purity materials makes them ideal for industries such as aerospace, electronics, and advanced materials.

Q10: What maintenance is required for a vacuum carbon tube furnace?

A10: Regular maintenance is essential to ensure optimal performance of your vacuum carbon tube furnace. This includes periodic checks for wear and tear of heating elements, seals, and vacuum systems. Cleaning the chamber and ensuring accurate calibration of gauges will also extend the lifespan of the furnace and maintain its efficiency. Always refer to the user manual for specific maintenance guidelines.

Technical Parameter of the 2000 degree Vertical Vacuum Carbon Tube Furnace

| Work area | Rate | Max.temp | ultra vacuum |

| Φ90×120㎜ | 25Kw | 2000℃ | 6.67×10-3Pa |

| Φ140×140㎜ | 40Kw | 2000℃ | 6.67×10-3Pa |

| Φ160×160㎜ | 50Kw | 2000℃ | 6.67×10-3Pa |

| Φ220×300㎜ | 85Kw | 2000℃ | 6.67×10-3Pa |

| Φ280×320㎜ | 100Kw | 2000℃ | 6.67×10-3Pa |

| Φ320×320㎜ | 120Kw | 2000℃ | 6.67×10-3Pa |

| Φ320×600㎜ | 210Kw | 2000℃ | 6.67×10-3Pa |