Product Description: 2300°C High Temperature Vacuum Graphite Furnace :

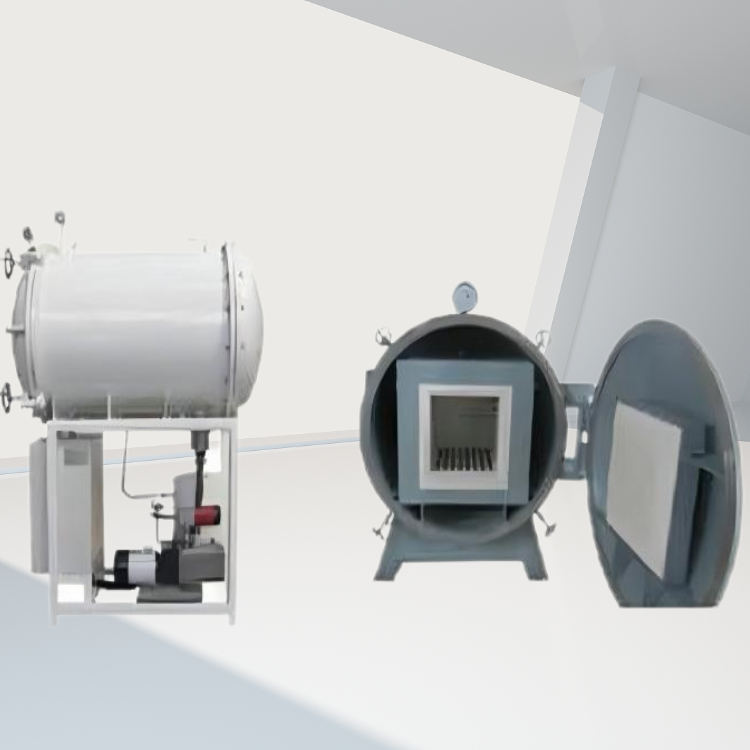

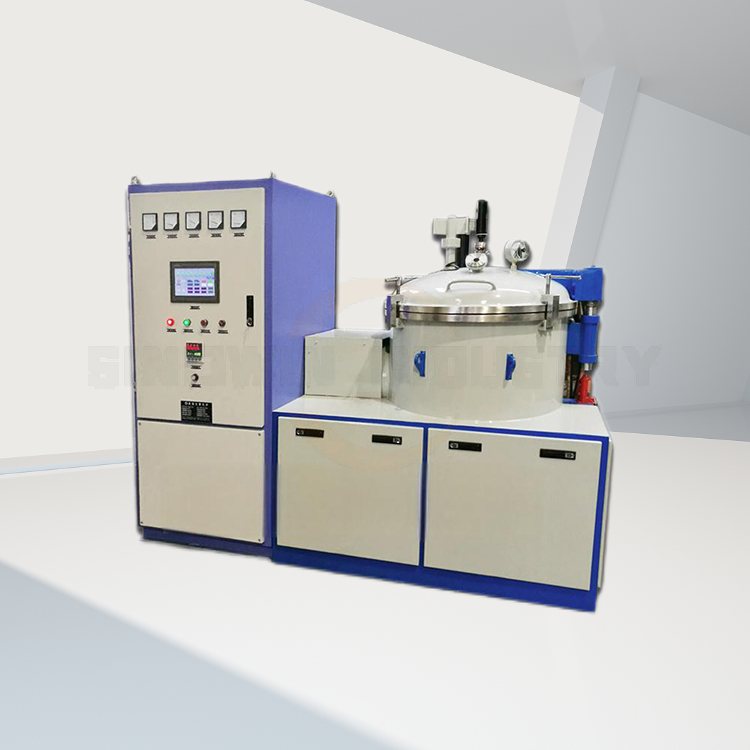

The SWVF-2300 vacuum furnace is designed and produced by Sinowin industry, Water-cooled stainless steel vacuum flanges with valves are installed to achieve a vacuum of 10-2 to10-5 torr through a mechanical or molecular vacuum pump. It is designed for calcining or annealing semiconductor wafers (up to 6″) under vacuum or various other gas atmospheres with a temperature up to 2300°C.

The high temperature vacuum furnace is a horizontal single-chamber structure, and its main body is a double-layer water-cooled structure, consisting of a furnace body, a heating system and a vacuum system ,water cooling system and electrical control parts.

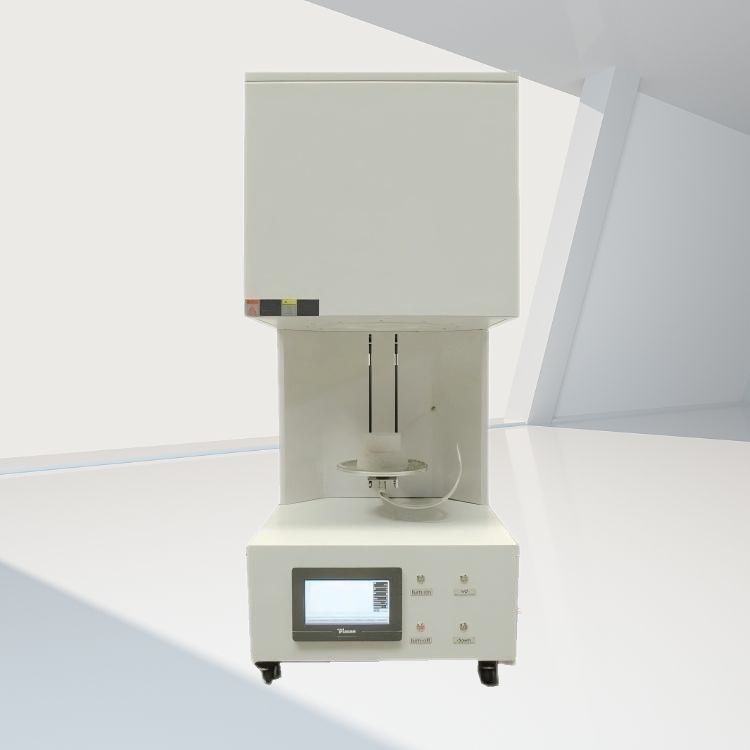

High temperature sintering furnace heating method USES to give graphite heating bar into low voltage (24-36v) large current, so that graphite heating Method of heating.Thyristor is used to regulate the voltage and the transformer to reduce the voltage.The temperature in the single temperature zone is controlled by a temperature controller .

Technical Parameter of the 2300°C High Temperature Vacuum Graphite Furnace :

2300°C High Temperature Vacuum Graphite Furnace |

|

| Work zone size | 200 200 200mm support customized bottom loading |

| Thermal keep room | Stainless steel Angle as the frame, stainless steel mesh paving, inner |

| lining multi – layer soft graphite felt | |

| Or composite hard graphite felt to form an insulation | |

| Alarm | over temperature /current /pressure,lack water |

| Max temperature | 2300C |

| Max working temperature | 2100C |

| Temperature Accuracy | Under full load,keep 1400C ≤±1℃(Insulation ring test) |

| Heating Rate | Under full load,from 100C to 1000C ,15C per minute.from 1000C to |

| max temperature 10C per minute | |

| Power | 90KWA 380V(±10%) 60HZ |

| Temperature Control | PLC touch screen controller |

| Furnace Atmosphere | Nitrogen, Argon and other inert gases |

| cool water flow meter | 10m3/h |

| water pressure | 0.25Mpa |

| Thermocouples | 3 point B type +infrared thermometer |

| Controller measure range | 0-2500℃ |

| Vacuum pump | mechanical pump, roots pump ,diffusion pump |

| vacuum degree | 5X10-5 torr. |

| Vacuum meter | digital vacuum meter |

| Heating Element | adopt the cage structure consisting of graphite rods. |

| The design and arrangement of graphite rod are considered in vacuum | |

| and atmosphere. | |

| Under the condition of temperature field uniformity control, and easy replacement. | |

| Outer sheel | The steel plate is welded to the water-cooled sandwich cylinder, are made of stainless steel, flange made of stainless steel, with the double layer structure, inner layer and outer layer |

| two ends of the water-cooled furnace door.The connection between | |

| the furnace body and each part is made of four ferro rubber Ring seal. | |

| Other parts of the system may be installed on the furnace or connected to the furnace body. | |

| Vacuum acquisition system | It consists of a mechanical pump, roots pump ,diffusion pump ,an inflatable electromagnetic vacuum valve, |

| a vacuum butterfly valve, a diaphragm valve and a pipe.Aerated electromagnetic vacuum. The valve and the slide valve pump at the same time to prevent the pump oil ,back flow into the vacuum system.1 vacuum diaphragm valve for filling process gas,1 only used for filling air in front of the furnace to break the vacuum. | |

| OEM/ODM Service | |

| Sinowin FURNACE HAVE OWN DEVELOPMENT TEAM SUPPORT ALL KINDS OEM /ODM DESIGN .SPECIALLY IN HEATING EQUIPMENTS FOR 15 YEARS .ENSURE BEST QUALITY PRODUCTS AND AFTER SALE SERVICE . | |

Whether you’re in the manufacturing sector or a research facility, our 2300°C High Temperature Vacuum Graphite Furnace

is an indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with user-friendly operation. Donot hesitate to Contact us at once for any further information of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Technical Parameter of the 2300°C High Temperature Vacuum Graphite Furnace :

2300°C High Temperature Vacuum Graphite Furnace |

|

| Work zone size | 200 200 200mm support customized bottom loading |

| Thermal keep room | Stainless steel Angle as the frame, stainless steel mesh paving, inner |

| lining multi – layer soft graphite felt | |

| Or composite hard graphite felt to form an insulation | |

| Alarm | over temperature /current /pressure,lack water |

| Max temperature | 2300C |

| Max working temperature | 2100C |

| Temperature Accuracy | Under full load,keep 1400C ≤±1℃(Insulation ring test) |

| Heating Rate | Under full load,from 100C to 1000C ,15C per minute.from 1000C to |

| max temperature 10C per minute | |

| Power | 90KWA 380V(±10%) 60HZ |

| Temperature Control | PLC touch screen controller |

| Furnace Atmosphere | Nitrogen, Argon and other inert gases |

| cool water flow meter | 10m3/h |

| water pressure | 0.25Mpa |

| Thermocouples | 3 point B type +infrared thermometer |

| Controller measure range | 0-2500℃ |

| Vacuum pump | mechanical pump, roots pump ,diffusion pump |

| vacuum degree | 5X10-5 torr. |

| Vacuum meter | digital vacuum meter |

| Heating Element | adopt the cage structure consisting of graphite rods. |

| The design and arrangement of graphite rod are considered in vacuum | |

| and atmosphere. | |

| Under the condition of temperature field uniformity control, and easy replacement. | |

| Outer sheel | The steel plate is welded to the water-cooled sandwich cylinder, are made of stainless steel, flange made of stainless steel, with the double layer structure, inner layer and outer layer |

| two ends of the water-cooled furnace door.The connection between | |

| the furnace body and each part is made of four ferro rubber Ring seal. | |

| Other parts of the system may be installed on the furnace or connected to the furnace body. | |

| Vacuum acquisition system | It consists of a mechanical pump, roots pump ,diffusion pump ,an inflatable electromagnetic vacuum valve, |

| a vacuum butterfly valve, a diaphragm valve and a pipe.Aerated electromagnetic vacuum. The valve and the slide valve pump at the same time to prevent the pump oil ,back flow into the vacuum system.1 vacuum diaphragm valve for filling process gas,1 only used for filling air in front of the furnace to break the vacuum. | |

| OEM/ODM Service | |

| Sinowin FURNACE HAVE OWN DEVELOPMENT TEAM SUPPORT ALL KINDS OEM /ODM DESIGN .SPECIALLY IN HEATING EQUIPMENTS FOR 15 YEARS .ENSURE BEST QUALITY PRODUCTS AND AFTER SALE SERVICE . | |