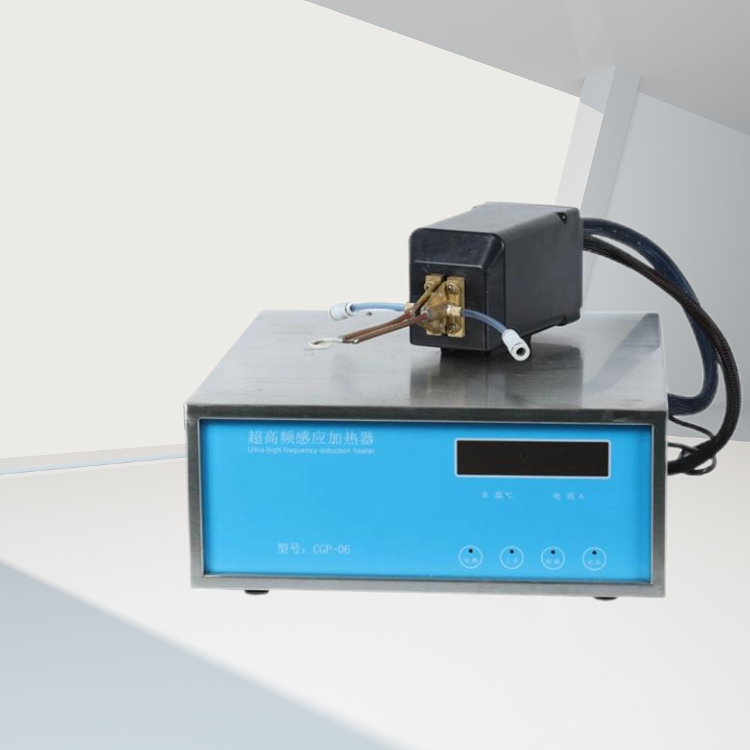

Product Title: 25KVA High Frequency Welding Machine

Product Description:

The 25KVA High Frequency Welding Machine is an induction heating device designed and produced by sinowin industry for precision and efficiency in a variety of applications. With a powerful oscillating power of 25KVA and an input power of 15KW, this machine is engineered to meet the demanding needs of modern welding and heating processes.

Key Technical Specifications:

- Oscillation Power:25KVA

- Input Power:15KW

- Oscillation Frequency:30—80KHZ

- Input Voltage:Three-phase 380V, 50 or 60HZ

- Cooling Water Requirements:2Mpa, 4 – 5 L/min

- Duty Cycle:80%

- Automatic Control Timing Function:Heating time, insulation time, cooling time: 1—99 seconds or 0.1-9.9 seconds

Applications:

The versatility of the 25KVA High Frequency Welding Machine allows it to excel in several industries and applications, including:

- Hot Forging Industry: Ideal for bending and forming steel plates and round bars, including full forging, localized forging, fastener forging, drill bit pressing, and the hot forming of various standard and non-standard components. Perfect for pre-heating tools such as pliers and wrenches.

- Welding Applications: Suitable for soldering various metal products (tin soldering, silver soldering, copper soldering), including the welding of cutting tools, steel pipes, diamond tools, and various mining machine bits and drill bits.

- Heat Treatment: Exceptional for the quenching, annealing, and tempering of various metals, especially for localized treatment. This machine is perfect for heat treatment of various hardware tools, hand tools, automotive parts, gears, sprockets, hydraulic components, and machine tool guide rails.

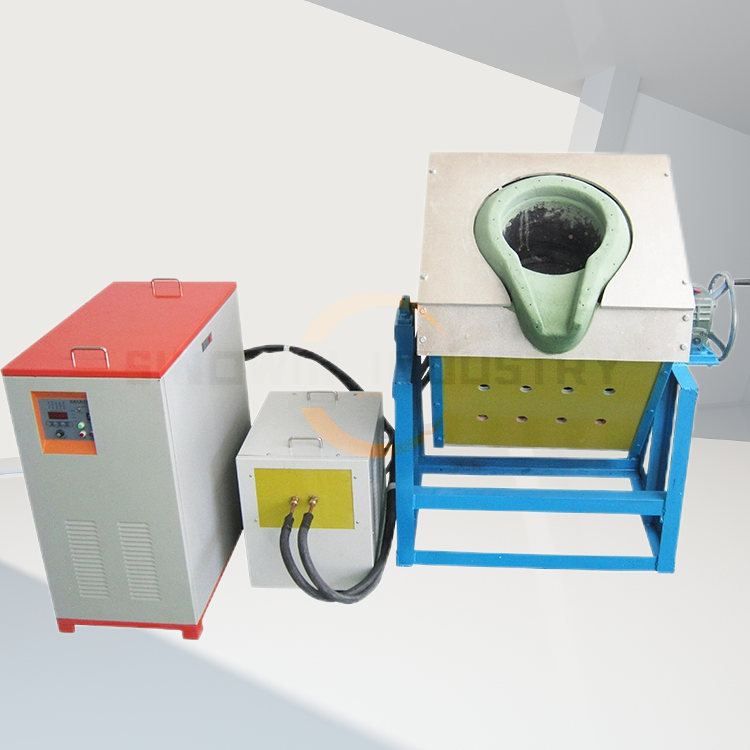

- Melting: Efficient for casting melting, steel mill melting, precious metal melting, and small-scale melting in laboratories.

The 25KVA High Frequency Welding Machine designed and produced by sinowin industry is more than just a welding tool; it is an advanced induction heating system that operates through a high-frequency alternating current, generating an electromagnetic field within the induction coil. This process allows for localized heat generation on the surface of the metal workpieces, which is ideal for various welding techniques.

Induction Brazing: This technique involves placing the metal workpiece, often made of copper, within the induction coil and applying high-frequency alternating current. The induced electromagnetic field generates eddy currents that produce localized heating on the workpiece. As the workpiece reaches the melting temperature of the brazing filler, welding can commence, ensuring a strong bond.

The 25KVA High Frequency Welding Machine delivers not only speed but also quality in the welding process. With its ability to focus heat on the surface, it minimizes the risk of oxidation, sulfide formation, decarburization, discoloration, and distortion, ultimately reducing costs while enhancing weld integrity.

Why Choose the 25KVA High Frequency Welding Machine?

Designed and produced by sinowin industryfor professionals who demand precision and efficiency, this high-frequency welding machine ensures optimal performance across a broad range of materials, including tungsten steel, alloy steel, copper, aluminum, stainless steel, and more. With its exceptional adaptability, you can utilize diverse welding rods and materials such as brass, bronze, silver, and tin for various applications.Sinowin industry supply the indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with long-term trusted and reliable service. And we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Please feel free to consult for any additional questions or specifics related to your requirements for the 25KVA High Frequency Welding Machine. Whether you are in woodworking, electronics, or manufacturing, the 25KVA High Frequency Welding Machine is your go-to equipment for high-quality welding results.