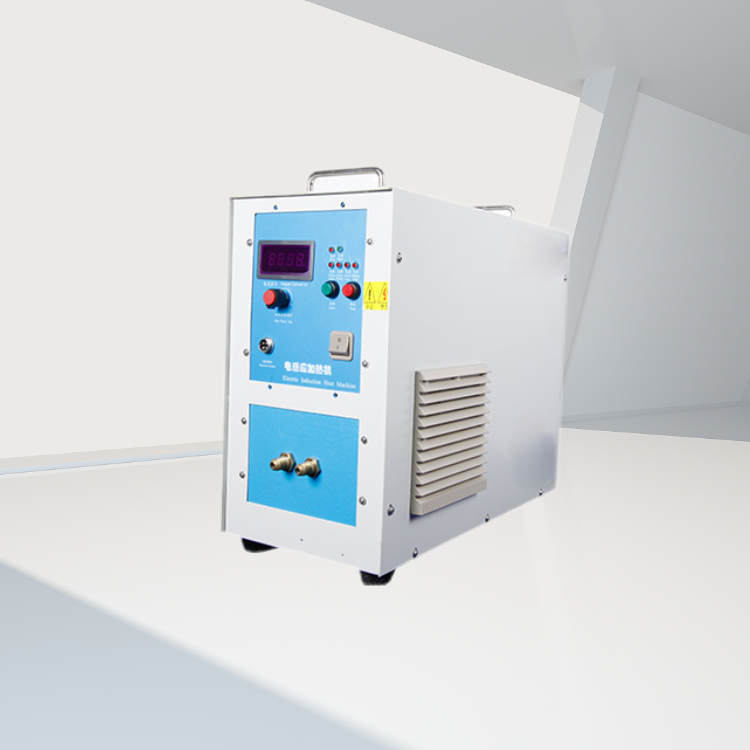

Product Description: 35kW Medium Frequency Induction Heating Furnace Power Supply

Our 35kW Medium Frequency Induction Heating Furnace Power Supply is an advanced solution designed to meet the heating requirements of various industrial applications. This induction furnace operates at an oscillation frequency range of 1-20kHz, tailored specifically to optimize heating processes for your workpieces.

Key Technical Parameters:

- Input Power:35kW

- Oscillation Frequency:1-20kHz (configurable based on heating requirements)

- Iutput Voltage:70-550V

- Input Power Supply:Three-phase 380V, 50 or 60Hz

- Load Continuity Rate:100% for 24 hours, designed for continuous operation

- Dimensions (cm):52L x 27W x 45H

- Weight:34kg

- Output Current:10-70A

- Input Power Cable Requirement:12mm² soft copper wire

- Equipment Ground Wire:6mm² soft copper wire

- Input Power Air Switch Requirement:3x80A

- Cooling Water Requirement for Induction Furnace:≥0.2Mpa, ≥10L/min

- Cooling Water Requirement for Power Supply:≥0.2Mpa, ≥4L/min

- Water Circulation:One inlet and one outlet

- Inlet and Outlet Pipe Dimensions:Inlet (8mm), Outlet (8mm), Valve (25mm)

- Included Boost Pump:5kW, with a lift of 30-50 meters, accompanied by a 4 cubic meter water tank

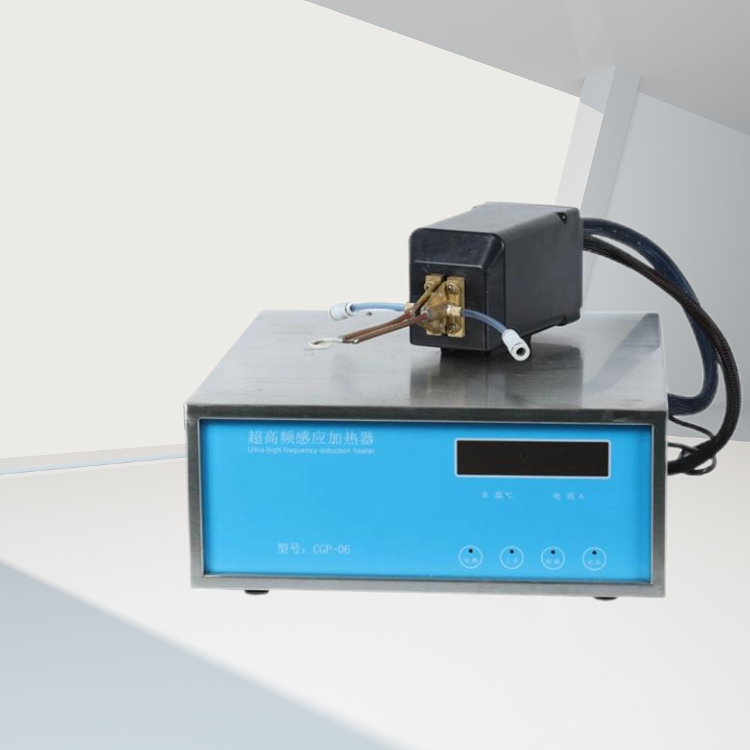

Overview of Medium Frequency Induction Heating Equipment:

The Medium Frequency Induction Heating Furnace designed and produced by sinowin industryoperates in the frequency range of 1-20kHz and offers power capacities from 15 to 160kW. Due to its lower frequency, this product is suitable for applications requiring deep heating or thermal penetration, such as bar material forging, melting of metals up to 200kg, heat fitting, overall tempering of molds, and pre-heating before welding.

Advantages of the 35kW Medium Frequency Induction Heating Furnace Power Supply:

This induction heating furnace power supply utilizes full solid-state IGBT frequency conversion and power regulation technology, featuring comprehensive protective functions including overcurrent protection, low water protection, overheat protection, over-voltage protection, short circuit protection, and phase loss protection. These features enhance reliability while simplifying maintenance tasks.

The equipment boasts multiple display functionalities, such as frequency, current, voltage, and power readings, which provide intuitive insights into operational status and serve as a guide for designing induction coils and capacitor adjustments.

The SWI series medium frequency furnace designed and produced by sinowin industry is compact and lightweight, saving up to 10 times the production space compared to conventional SCR-based medium frequency power supplies. Engineered for 100% full load capability and 24-hour continuous operation, this unit is highly efficient, ensuring high power factors and energy efficiency across its entire power range.

Elevate your heating operations with the reliable and efficient 35kW Medium Frequency Induction Heating Furnace Power Supply – engineered for performance, safety, and user-friendliness.Please feel free to consult for any additional questions or specifics related to your requirements for our Medium Frequency Induction Heating Furnace!and Sinowin industry not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment

Main parameters of power supply for medium-frequency smelting furnace:

| Model | SWI—15 | SWI—25 | SWI—35 | SWI—45 | SWI—70 | SWI—90 | SWI—110 | SWI—160 |

| Input power | 15KVA | 25KVA | 35KVA | 45KVA | 70KVA | 90KVA | 110KVA | 160KVA |

| Output current | 3~22A | 5~45A | 10~70A | 15~95A | 20~130A | 25~170A | 30~200A | 30~250A |

| Output voltage | 70~520V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V |

| Power supply | Three-phase 380V ± 20% 50 or 60 HZ | |||||||

| Output oscillation frequency | 1 KHZ ~ 20 KHZ according to the customer work-piece heating requirements | |||||||

| Cyclic duration factor | 100% 24 hours, continuous work | |||||||

| Power weight | 28KG | 30KG | 40KG | 50KG | 60KG | 80KG | 100KG | 122KG |

| Power supply volume (width, height and length) CM | 27×45×46 | 27×45×52 | 35×55×65 | 50×88×75 | 50×88×75 | |||

| Complete set of cooling water requirements of the Medium-frequency induction furnace | ≥0.2Mpa ≥6L/Min | ≥0.3Mpa ≥10L/Min | ≥0.3Mpa ≥20L/Min | ≥0.3Mpa ≥25L/Min | ||||

| Requirements for cooling water of medium-frequency power supply | ≥0.2Mpa ≥3L/Min | ≥0.2Mpa ≥4L/Min | ≥0.2Mpa ≥6L/Min | ≥0.2Mpa ≥6L/Min | ||||

| Power waterway | One Water Inlet; One Water Outlet | One Water Inlet; Three Water Outlet | ||||||

Specification and heating capacity of the Intermediate Frequency Induction Smelting Furnace:

| Specifications | Steel, iron | Gold, silver, copper, and tin | Aluminum, aluminum alloy | Input voltage | Input power |

| SWI-15 Smelting Furnace | 2kg | 10kg | 3kg | 380v | 15kw |

| SWI-25 Smelting Furnace | 4kg | 20kg | 6kg | 380v | 25kw |

| SWI-35 Smelting Furnace | 8kg | 40kg | 10kg | 380v | 35kw |

| SWI-45 Smelting Furnace | 12kg | 50kg | 20kg | 380v | 45kw |

| SWI-70 Smelting Furnace | 25kg | 100kg | 30kg | 380v | 70kw |

| SWI-90 Smelting Furnace | 40kg | 120kg | 50kg | 380v | 90kw |

| SWI-110 Smelting Furnace | 50kg | 150kg | 80kg | 380v | 110kw |

| SWI-160 Smelting Furnace | 70kg | 250kg | 200kg | 380v | 160kw |

| Note | The heating capacity of each type of smelting furnace is listed in the table below. When the furnace is cold, the smelting time for each furnace is 50 to 60 minutes. When the furnace is hot, the smelting time for each furnace is 20 to 30 minutes. | ||||