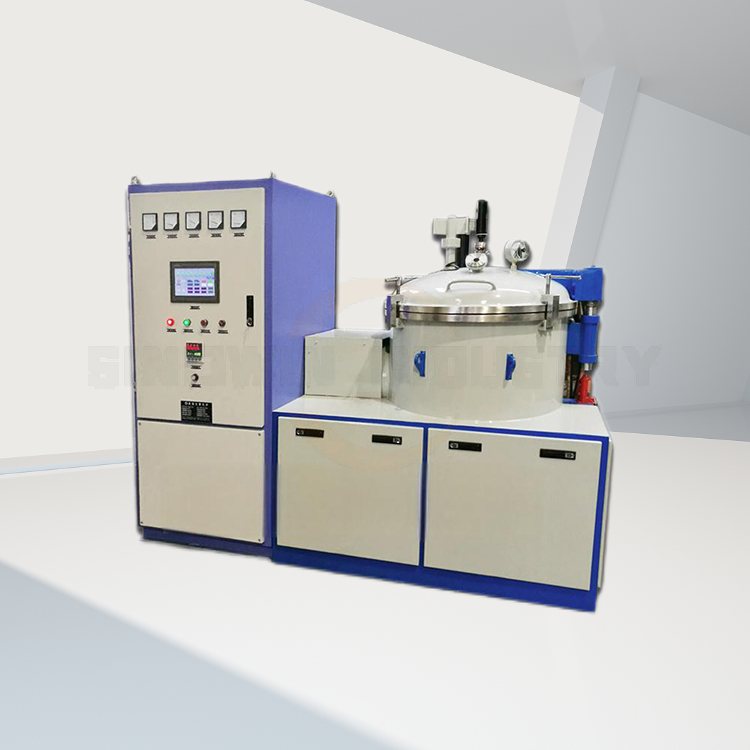

Product Description:

The Carbon Fiber High-Temperature Graphitization Furnace is a heating treatment solution specifically for the production of high-modulus carbon fibers. This advanced continuous furnace operates at an exceptional maximum temperature of 3000°C, utilizing an uninterrupted online processing method for optimal efficiency.

Key Features:

- High-Temperature Capability: This furnace operates at temperatures reaching up to 3000°C, ensuring the precise conditions necessary for high-quality carbon fiber graphitization.

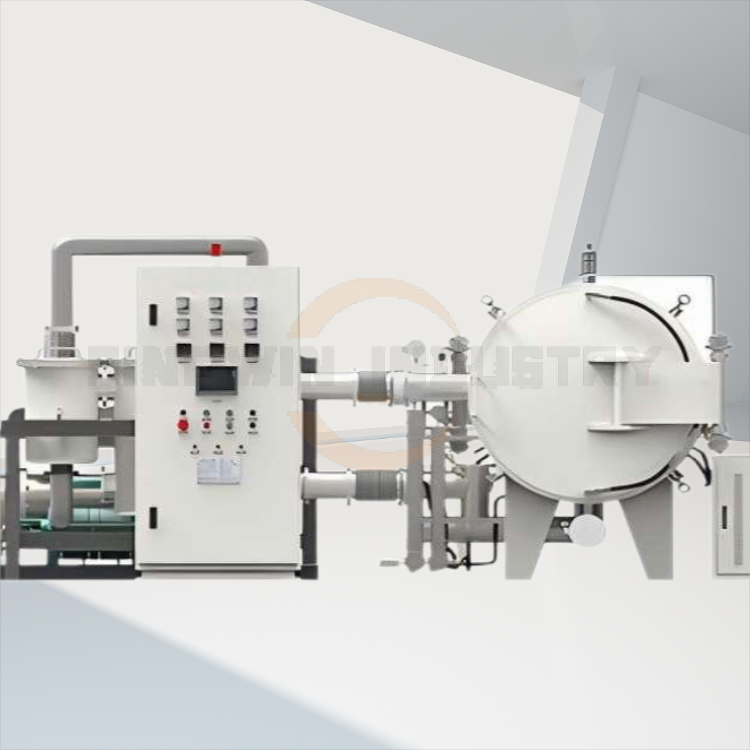

- Continuous Operation Design: The furnace’s continuous production setup allows carbon fiber filaments to enter from one end and exit from the other, facilitating simultaneous feeding and collection for enhanced production efficiency.

- Vertical Temperature Measurement: Equipped with an innovative vertical temperature measurement technology, the placement of thermometers does not interfere with the wire drawing process, ensuring accurate temperature control.

- Air-Sealed Structure: The furnace features a gas curtain sealing mechanism that effectively prevents the entry of air, maintaining the purity of the graphitization environment.

- Vacuum Pump Integration: A built-in vacuum pump enables rapid gas replacement, streamlining the processing of carbon fibers.

- Intelligent Temperature Control System: This furnace incorporates a digital display intelligent temperature control system that fully automates the measurement and temperature regulation process. Users can program and store up to twenty distinct heating profiles, each with 400 segments, for customized temperature curves.

- Comprehensive PLC Control System: The furnace comes with an advanced PLC water, electricity, and gas automatic control and protection system. The connection cables between the control cabinet and the furnace body can extend up to 20 meters for remote operation.

- High-Performance Graphite Tubes: The furnace is outfitted with high-performance isotropic graphite tubes, which offer significantly lower thermal loss at the same graphitization temperature and boast a lifespan nearly double that of standard graphite.

The Carbon Fiber High-Temperature Graphitization Furnace is ideal for industries focused on the high-temperature graphitization treatment of carbon fibers, ensuring top-quality output and enhanced production capabilities.Whether you are in research, analysis, or manufacturing, the Carbon Fiber High-Temperature Graphitization Furnace supplied from SINOWIN INDUSTRY is one guaranteed option for your heating treatment industry.

.

Technical Parameter of the 3000 degree Carbon Fiber High-Temperature Graphitization Furnace

| Work Size DXL(mm) | Ф50X600 | Ф100X600 | Ф200X600 | Ф300X600

|

| Work Temperature (℃) | 2800 | 2800 | 2800 | 2800

|

| Power(KW) | 60 | 80 | 160 | 200

|

| Temperature Uniformity(℃) | ±20 | ±20 | ±20 | ±20

|

| Voltage (V) | 3phase,380 | |||

| Atmosphere |

High Vacuum(optional)/ Vacuum /N2,Ar or other inert gases |

|||

| The parameter of the High-Temperature Graphitization Furnace for Carbon Fiber above could be customized according to your detailed requirement | ||||

Q&As of the Carbon Fiber High-Temperature Graphitization Furnace:

Q1: What is the maximum temperature that the carbon fiber high-temperature graphitization furnace can achieve?

A1: The carbon fiber high-temperature graphitization furnace can achieve a maximum operational temperature of 3000°C. This allows for an extensive range of applications in various industries that require high-temperature processing.

Q2: How does the continuous production feature enhance the efficiency of the furnace?

A2: The continuous production design of the furnace enables carbon fiber to be fed in from one end while being processed and removed from the other end. This simultaneous feed and retrieval process significantly increases production efficiency, thereby reducing downtime and enhancing overall productivity.

Q3: What type of temperature measurement technology is employed in the furnace?

A3: This furnace uses advanced longitudinal vertical temperature measurement technology. This design ensures that the placement of the temperature measuring device does not interfere with the carbon fiber handling process, ensuring accurate temperature readings without compromising operational flow.

Q4: How does the air curtain sealing structure benefit the operation of the furnace?

A4: The air curtain sealing structure effectively prevents external air from entering the furnace during operation. This is vital in maintaining a controlled environment within the furnace, allowing for consistent processing conditions and improved product quality.

Q5: Is the furnace equipped for gas replacement, and how does it work?

A5: Yes, the furnace is equipped with a vacuum pump that facilitates rapid gas replacement. This feature allows for quick evacuation of unwanted gases and ensures a low-pressure environment necessary for optimal graphitization processes.

Q6: Can the temperature control process be automated?

A6: Absolutely. The furnace features a digital intelligent temperature control system that fully automates the temperature measurement and control processes. The system can follow pre-set heating curves, store up to twenty distinct heating programs, and manage 400 segments of different processing profiles for versatility in operation.

Q7: What type of materials are used for the graphite tubes in this furnace?

A7: High-performance homogeneous graphite is used for the graphite tubes. Compared to standard graphite, this material offers lower thermal losses at the same graphitization temperature, effectively doubling the lifespan of the furnace components.

Q8: How does the PLC control system enhance safety and operation?

A8: The comprehensive PLC water, electricity, and gas automatic control and protection system ensures safe operation by closely monitoring all operational parameters. Additionally, the control cabinet can be connected to the furnace with cables up to 20 meters long, allowing for convenient remote operation and monitoring to enhance user safety and ease of access.

Donot hesitate to Contact us at once for quotation of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Technical Parameter of the 3000 degree Carbon Fiber High-Temperature Graphitization Furnace

| Work Size DXL(mm) | Ф50X600 | Ф100X600 | Ф200X600 | Ф300X600

|

| Work Temperature (℃) | 2800 | 2800 | 2800 | 2800

|

| Power(KW) | 60 | 80 | 160 | 200

|

| Temperature Uniformity(℃) | ±20 | ±20 | ±20 | ±20

|

| Voltage (V) | 3phase,380 | |||

| Atmosphere |

High Vacuum(optional)/ Vacuum /N2,Ar or other inert gases |

|||

| The parameter of the High-Temperature Graphitization Furnace for Carbon Fiber above could be customized according to your detailed requirement | ||||