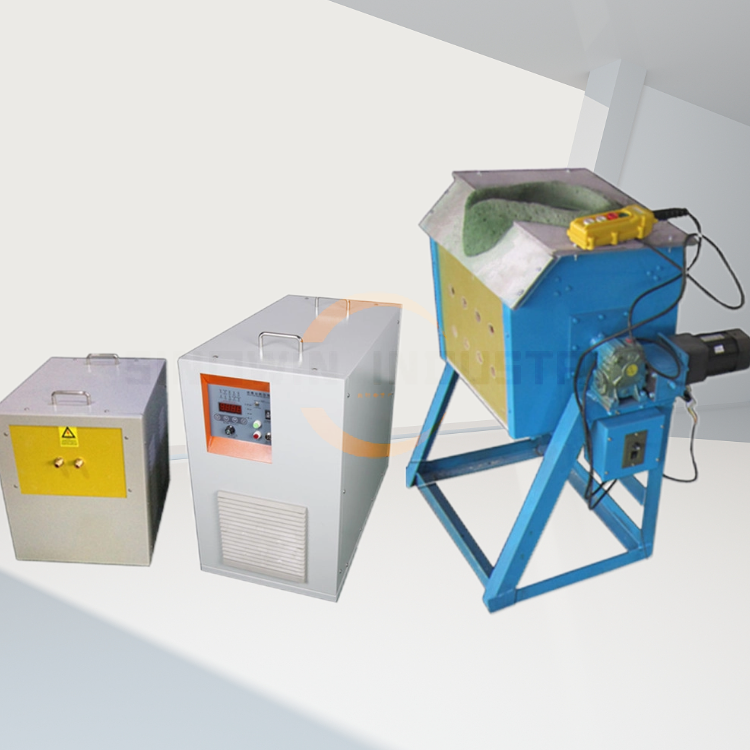

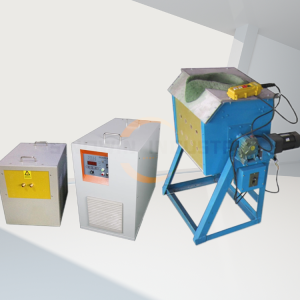

Product Description:

Our Electric Tilting Medium Frequency Melting Furnace designed and produced by sinowin industry is used for high-efficiency metal melting and refining. This melting furnace is engineered to cater to a wide range of needs, from small-scale operations to industrial applications, with a versatile capacity ranging from 3KG to 300KG for non-ferrous metals and select non-metallic materials.

Key Components:

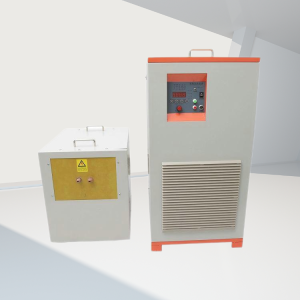

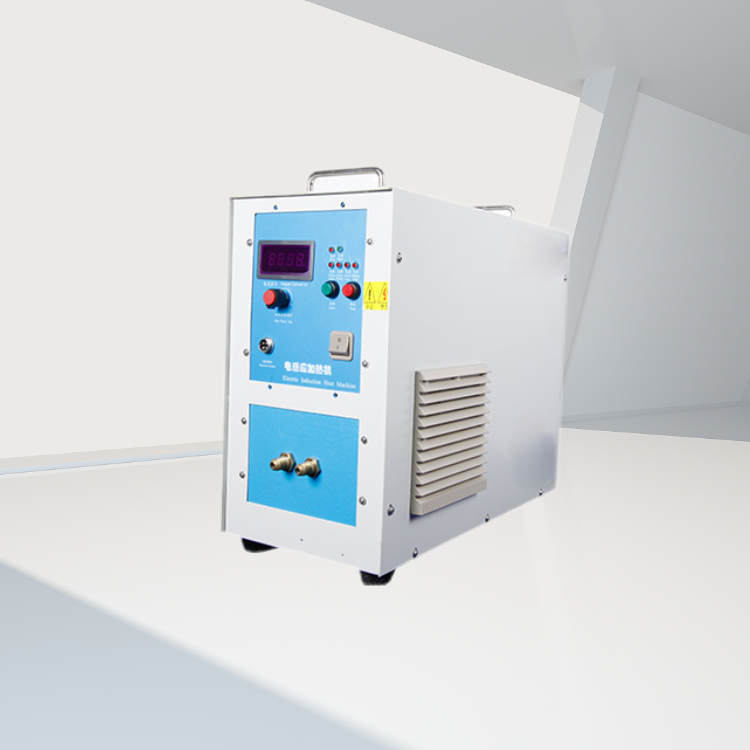

- SWI-15 to SWI-160 Medium Frequency Power Supply – Ensures stable and reliable performance.

- Compensating Capacitor Box – Designed to enhance the efficiency of the melting process.

- Electric Tilting Melting Furnace – Facilitates easy handling and operation, allowing you to pour molten metal effortlessly.

Structure of Medium Frequency Melting Furnace:

The key components of this system include the medium frequency power supply, capacitor box, and the melting furnace itself. Depending on specific applications, additional devices such as infrared temperature measuring instruments and temperature controllers may be included. Our melting furnaces are categorized into three types: tilt type, ejector type, and fixed type. The tilt type can further be classified into mechanical, electric, and hydraulic variants.

Key Features:

- Oscillation Frequency: Operates within a range of 2-20 kHz, ensuring optimal performance for diverse applications.

- Metal Melting Capacity: Suitable for melting non-ferrous metals ranging from 3 KG to 300 KG, including platinum, gold, silver, copper, steel, aluminum, active carbon gray, gold sand, electrolytic copper, and tin residues.

- Rapid Melting Process: The high efficiency of our furnace enables a single melting capacity from 1 gram to 100 kilograms, with a melting time ranging from 5 to 30 minutes, achieving furnace temperatures of 1000 to 1600 degrees Celsius.

- Versatile Applications: This equipment is perfect for factory production, small workshops, educational institutions, and research experiments requiring small sample melts.

- Fast Heating: With a remarkable 95% heating efficiency, the melting furnace allows adjustable heating speeds tailored to your needs.

- Energy Efficient & Eco-Friendly: Designed to replace traditional methods such as oxy-acetylene flames and coal-fired furnaces, this medium frequency melting furnace provides a durable, energy-saving solution.

- Easy Installation: Simply connect the power supply and cooling water pipes, and the melting furnace is ready to use. Its compact size and lightweight design ensure convenience.

- User-Friendly Operation: The melting furnace enables straightforward operation, achievable in just a few minutes without the need for professional installation expertise.

- Quick Start-Up: Once connected to water and power, the furnace can initiate heating, sustaining a continuous melting capability around the clock.

- Safety & Reliability: Equipped with overpressure, overcurrent, overheating, and low-water alarms, the melting furnace guarantees enhanced operational safety.

- Electromagnetic Stirring Function: This feature promotes uniform molten materials, aids in slag floating, reduces impurities, and results in a cleaner, more luminous cast without shrink holes or porosity.

Technical Specifications:

Main parameters of power supply for medium-frequency smelting furnace

| Model | SWI—15 | SWI—25 | SWI—35 | SWI—45 | SWI—70 | SWI—90 | SWI—110 | SWI—160 |

| Input power | 15KVA | 25KVA | 35KVA | 45KVA | 70KVA | 90KVA | 110KVA | 160KVA |

| Output current | 3~22A | 5~45A | 10~70A | 15~95A | 20~130A | 25~170A | 30~200A | 30~250A |

| Output voltage | 70~520V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V |

| Power supply | Three-phase 380V ± 20% 50 or 60 HZ | |||||||

| Output oscillation frequency | 1 KHZ ~ 20 KHZ according to the customer work-piece heating requirements | |||||||

| Cyclic duration factor | 100% 24 hours, continuous work | |||||||

| Power weight | 28KG | 30KG | 40KG | 50KG | 60KG | 80KG | 100KG | 122KG |

| Power supply volume (width, height and length) CM | 27×45×46 | 27×45×52 | 35×55×65 | 50×88×75 | 50×88×75 | |||

| Complete set of cooling water requirements of the Medium-frequency induction furnace | ≥0.2Mpa ≥6L/Min | ≥0.3Mpa ≥10L/Min | ≥0.3Mpa ≥20L/Min | ≥0.3Mpa ≥25L/Min | ||||

| Requirements for cooling water of medium-frequency power supply | ≥0.2Mpa ≥3L/Min | ≥0.2Mpa ≥4L/Min | ≥0.2Mpa ≥6L/Min | ≥0.2Mpa ≥6L/Min | ||||

| Power waterway | One Water Inlet; One Water Outlet | One Water Inlet; Three Water Outlet | ||||||

Main induction smelting furnace specifications and heating capacity:

| Specifications | Steel, iron | Gold, silver, copper, and tin | Aluminum, aluminum alloy | Input voltage | Input power |

| SWI-15 Smelting Furnace | 2kg | 10kg | 3kg | 380v | 15kw |

| SWI-25 Smelting Furnace | 4kg | 20kg | 6kg | 380v | 25kw |

| SWI-35 Smelting Furnace | 8kg | 40kg | 10kg | 380v | 35kw |

| SWI-45 Smelting Furnace | 12kg | 50kg | 20kg | 380v | 45kw |

| SWI-70 Smelting Furnace | 25kg | 100kg | 30kg | 380v | 70kw |

| SWI-90 Smelting Furnace | 40kg | 120kg | 50kg | 380v | 90kw |

| SWI-110 Smelting Furnace | 50kg | 150kg | 80kg | 380v | 110kw |

| SWI-160 Smelting Furnace | 70kg | 250kg | 200kg | 380v | 160kw |

| Note | The heating capacity of each type of smelting furnace is listed in the table below. When the furnace is cold, the smelting time for each furnace is 50 to 60 minutes. When the furnace is hot, the smelting time for each furnace is 20 to 30 minutes. | ||||

Melting Principle:

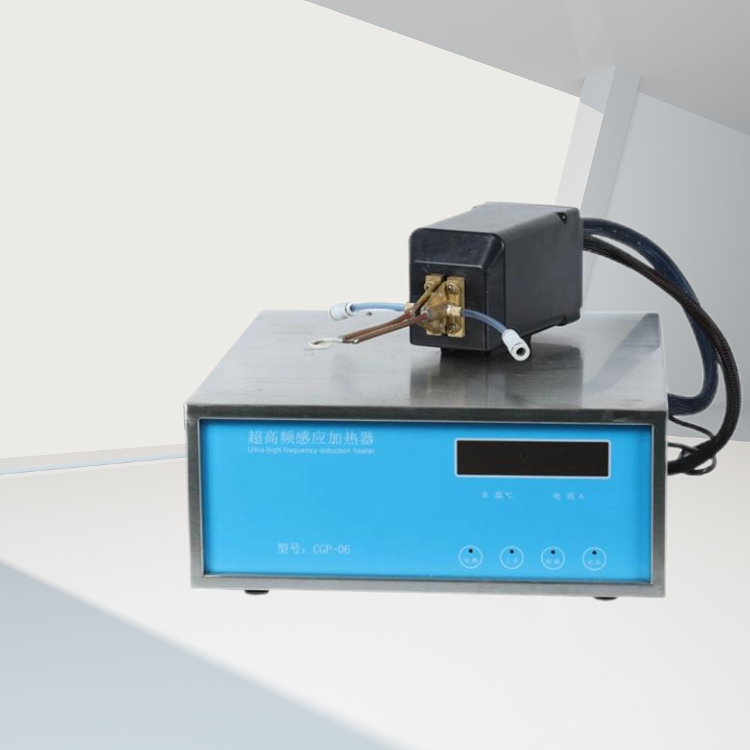

Utilizing cutting-edge solid-state Siemens IGBT inverter module technology, the melting furnace designed and produced by sinowin industryemploys an innovative magnetic field induction heating principle. The current flowing through the coil generates a magnetic field that induces eddy currents within the metal itself, creating instantaneous heating. This rapid heating process allows metals to reach melting points swiftly, transforming solid materials into liquid form efficiently.

What is the advantages of the Medium Frequency Induction Melting Furnace designed and produced by sinowin industry?

Compared to traditional coke furnaces, gas furnaces, fuel oil furnaces, and conventional resistance furnaces, the Electric Tilting Medium Frequency Melting Furnace offers remarkable advantages, including:

- Rapid Melting Speed:Melt metals quickly to meet high-demand production needs.

- Low Energy Consumption:Designed for energy efficiency, significantly reducing operational costs.

- Eco-Friendly:Contributes to a cleaner environment with reduced emissions.

- Compact Size:A space-saving solution ideal for both small workshops and large industrial settings.

- User-Friendly Operation:Engineered for simplicity, making it accessible for operators with varying skill levels.

Elevate your metal melting and refining processes with the Electric Tilting Medium Frequency Melting Furnace designed and produced by sinowin industry

, where innovation meets efficiency. Enjoy fast, reliable, and consistent results in all your melting needs!

Sinowin industry supply the indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with long-term trusted and reliable service.

Main parameters of power supply for medium-frequency smelting furnace

| Model | SWI—15 | SWI—25 | SWI—35 | SWI—45 | SWI—70 | SWI—90 | SWI—110 | SWI—160 |

| Input power | 15KVA | 25KVA | 35KVA | 45KVA | 70KVA | 90KVA | 110KVA | 160KVA |

| Output current | 3~22A | 5~45A | 10~70A | 15~95A | 20~130A | 25~170A | 30~200A | 30~250A |

| Output voltage | 70~520V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V |

| Power supply | Three-phase 380V ± 20% 50 or 60 HZ | |||||||

| Output oscillation frequency | 1 KHZ ~ 20 KHZ according to the customer work-piece heating requirements | |||||||

| Cyclic duration factor | 100% 24 hours, continuous work | |||||||

| Power weight | 28KG | 30KG | 40KG | 50KG | 60KG | 80KG | 100KG | 122KG |

| Power supply volume (width, height and length) CM | 27×45×46 | 27×45×52 | 35×55×65 | 50×88×75 | 50×88×75 | |||

| Complete set of cooling water requirements of the Medium-frequency induction furnace | ≥0.2Mpa ≥6L/Min | ≥0.3Mpa ≥10L/Min | ≥0.3Mpa ≥20L/Min | ≥0.3Mpa ≥25L/Min | ||||

| Requirements for cooling water of medium-frequency power supply | ≥0.2Mpa ≥3L/Min | ≥0.2Mpa ≥4L/Min | ≥0.2Mpa ≥6L/Min | ≥0.2Mpa ≥6L/Min | ||||

| Power waterway | One Water Inlet; One Water Outlet | One Water Inlet; Three Water Outlet | ||||||

Main induction smelting furnace specifications and heating capacity:

| Specifications | Steel, iron | Gold, silver, copper, and tin | Aluminum, aluminum alloy | Input voltage | Input power |

| SWI-15 Smelting Furnace | 2kg | 10kg | 3kg | 380v | 15kw |

| SWI-25 Smelting Furnace | 4kg | 20kg | 6kg | 380v | 25kw |

| SWI-35 Smelting Furnace | 8kg | 40kg | 10kg | 380v | 35kw |

| SWI-45 Smelting Furnace | 12kg | 50kg | 20kg | 380v | 45kw |

| SWI-70 Smelting Furnace | 25kg | 100kg | 30kg | 380v | 70kw |

| SWI-90 Smelting Furnace | 40kg | 120kg | 50kg | 380v | 90kw |

| SWI-110 Smelting Furnace | 50kg | 150kg | 80kg | 380v | 110kw |

| SWI-160 Smelting Furnace | 70kg | 250kg | 200kg | 380v | 160kw |

| Note | The heating capacity of each type of smelting furnace is listed in the table below. When the furnace is cold, the smelting time for each furnace is 50 to 60 minutes. When the furnace is hot, the smelting time for each furnace is 20 to 30 minutes. | ||||