Product Description:

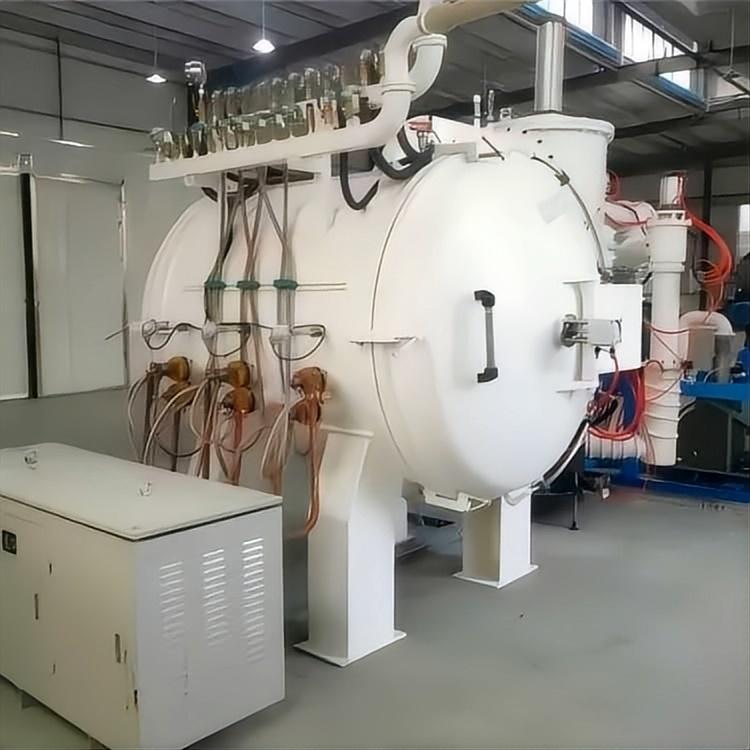

Our High-Temperature Film Carbonization Furnace, is specifically designed for the vacuum carbonization treatment of high thermal conductivity materials, particularly PI films. This advanced furnace stands out in the industry due to its exceptional features and innovative technology.

Key Features:

- High-Temperature Capability: Withstanding temperatures up to 1600℃, our furnace is perfectly suited for the carbonization process of PI films, ensuring optimal results.

- Precision Temperature Control: Equipped with high-precision thermocouples for zoned temperature measurement and control, this furnace guarantees accurate temperature readings and uniform heating throughout the chamber.

- Intelligent Digital Control System: The furnace utilizes a sophisticated digital temperature control system that automatically manages the heating process. It allows for the programming of a designated heating curve with the ability to store up to four different heating profiles, comprising a total of 40 segments.

- Data Recording Functionality: Our furnace features a data measurement and recording capability that logs temperature parameters. Users can easily query and export this data to a USB drive for further analysis.

- Reliable Safety Features: Utilizing a high-quality power controller from Taiwan, the furnace is designed with comprehensive protections against overloading, short circuits, false triggering, and over-voltage incidents.

- User-Friendly Interface: With a multi-channel data acquisition system and an intuitive human-machine interface, users can monitor and control the operating parameters with ease and clarity.

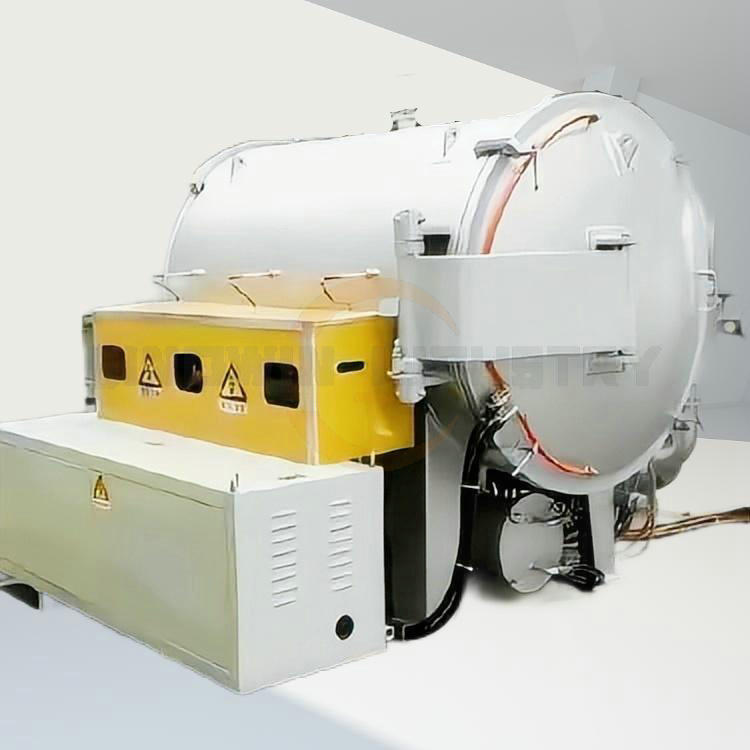

- Double-Layer Water-Cooled Design: The furnace is equipped with a unique double-layer water-cooled structure, facilitating negative pressure vacuum operation. This includes a vacuum pipeline interface complete with a vacuum break valve and gas inlet for enhanced functionality.

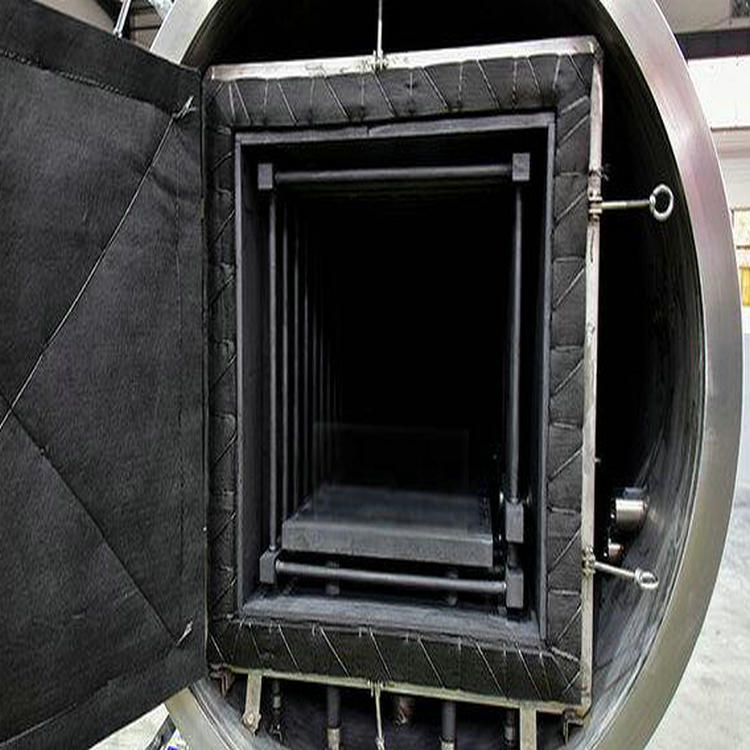

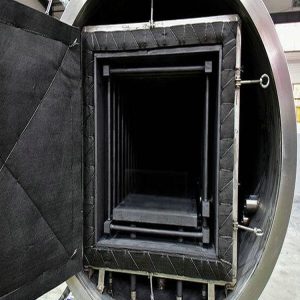

- Excellent Temperature Uniformity: Our square cage graphite rod heating arrangement ensures exceptional temperature uniformity, critical for effective carbonization.

- Convenient Operation: The horizontal design features dual doors at the front and back, allowing for easy loading and unloading, making the operation straightforward and efficient.

- Advanced Tar Filtration System: The cutting-edge tar filtration device maximizes the extraction of volatile components from the chamber, ensuring superior product quality and increased sintering output.

Technical Parameter:

| Work Size (mm) | 400X400X1200 | 500X500X1600 | 550X550X1600 | 600X600X1600 |

| Volume (L) | 192 | 400 | 484 | 576 |

| Work Temperature(℃) | 1500 | 1500 | 1500 | 1500 |

| Ultra Temperature(℃) | 1600 | 1600 | 1600 | 1600 |

| Power(KW) | 90 | 120 | 130 | 150 |

| Heating Method | Resistance Heating | |||

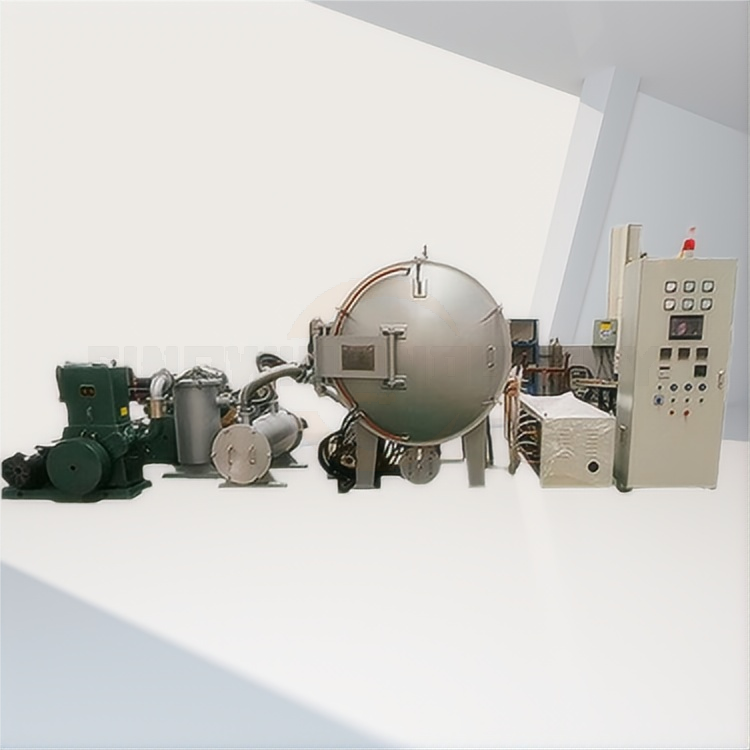

| Vacuum System | Slide valve vacuum pump or screw pump or oil ring pump unit | |||

| Atmosphere | Vacuum | |||

| Ultra Vacuum (Pa) | 40(Cooling Vacuum) | |||

The High-Temperature Film Carbonization Furnace designed and produced by nanyang sinowin industry combines high performance with advanced controls and user-friendly design, making it an ideal choice for professionals in need of reliable vacuum carbonization solutions for high thermal conductivity materials like PI films. Experience unrivaled precision and efficiency in your carbonization processes with our state-of-the-art furnace.

● Q1: What is the maximum temperature that the high-temperature carbonization furnace can reach?

- A1: The high-temperature carbonization furnace can reach temperatures up to 1600°C, making it ideal for the complete carbonization processing of PI films.

● Q2: How does the temperature control system work in this furnace?

- A2: Our furnace features a high-precision thermocouple zoning temperature measurement system that ensures accurate temperature readings and uniform heating throughout the furnace. It employs a digital intelligent temperature control system, which automatically completes the temperature measuring and controlling process with the capability to follow a predefined heating curve.

● Q3: Can I store different heating profiles in the furnace?

- A3: Yes, the furnace can store up to four different heating profiles, with each profile consisting of up to 40 segments. This allows for flexibility in varying your heating processes according to specific requirements.

● Q4: Is it possible to record temperature parameters and transfer data from the furnace?

- A4: Absolutely! The furnace is equipped with a data recording feature that enables it to log temperature parameters. This data can be easily queried and transferred to a portable USB drive for further analysis.

● Q5: How is the user interface and operation of the furnace designed?

- A5: The furnace incorporates a multi-channel data acquisition system with an intuitive human-machine interface, making it easy to monitor and operate. The operational parameters of the entire system are clearly displayed for effortless control.

● Q6: What are the features of the furnace’s body and structure?

- A6: The furnace features a double-layer water cooling structure and is capable of achieving negative pressure vacuum conditions. Additionally, it includes a vacuum pipeline interface, a vacuum breaking valve, and a gas injection port for enhanced functionality.

● Q7: How does the heating mechanism ensure temperature uniformity?

- A7: The furnace utilizes a square cage graphite rod combination heating method, which ensures excellent temperature uniformity across the working area. This design promotes consistent processing results for your materials.

● Q8: Is it easy to load and unload materials in this furnace?

- A8: Yes, loading and unloading are made convenient with the horizontal design of the furnace that features dual doors at both ends. This simplicity in design ensures efficient operations and minimal downtime during processing.

Whether you are in research, analysis, or manufacturing, the High-Temperature Film Carbonization Furnace for High Thermal Conductivity Materials (PI Film) supplied from SINOWIN INDUSTRY is your best choice.Donot hesitate to Contact us today for a quote and transform your scientific journey completely.

Technical Parameter of the 1600 °C High-Temperature Film Carbonization Furnace:

| Work Size (mm) | 400X400X1200 | 500X500X1600 | 550X550X1600 | 600X600X1600 |

| Volume (L) | 192 | 400 | 484 | 576 |

| Work Temperature(℃) | 1500 | 1500 | 1500 | 1500 |

| Ultra Temperature(℃) | 1600 | 1600 | 1600 | 1600 |

| Power(KW) | 90 | 120 | 130 | 150 |

| Heating Method | Resistance Heating | |||

| Vacuum System | Slide valve vacuum pump or screw pump or oil ring pump unit | |||

| Atmosphere | Vacuum | |||

| Ultra Vacuum (Pa) | 40(Cooling Vacuum) | |||