Product Description:

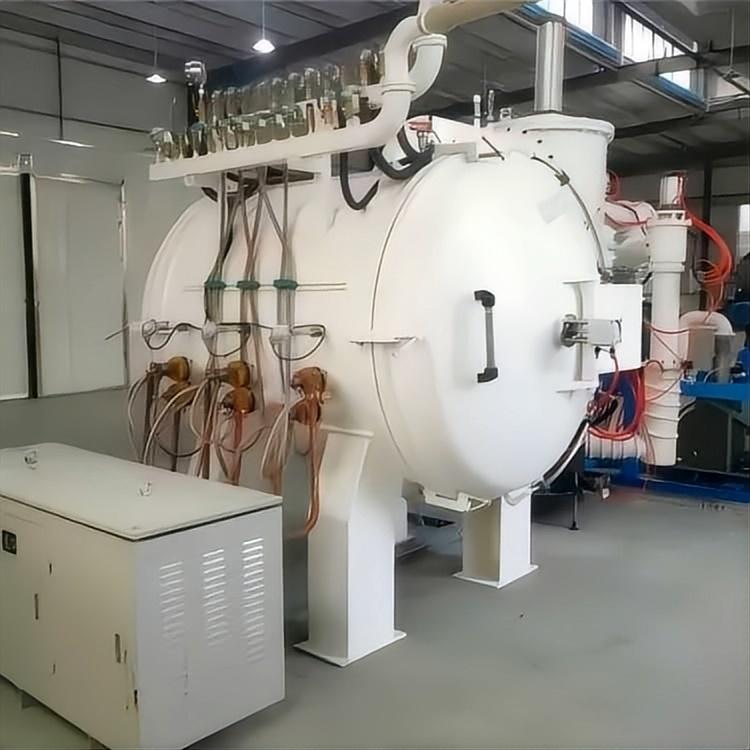

- The High Carbon Powder High Purity Graphite High Temperature Purification Furnace, is designed to enhance the purity and crystalline quality of high carbon powders, high purity graphite, and high purity insulation materials. Our high temperature purification furnace is engineered for a wide range of applications, making it an indispensable tool for industries requiring ultra-pure graphite products.

- The high purity graphite produced by our furnace is extensively utilized in semiconductor manufacturing processes, including the fabrication of graphite crucibles, graphite protective covers, and graphite boats. Additionally, it serves vital roles as heating elements, insulation materials, and chamber structures in vacuum furnaces and high temperature furnaces. In solar cell production, our high purity graphite acts as a supporting material for silicon crystal rods and multicrystalline furnace chambers.

- High carbon powder, on the other hand, finds its significance in the production of lithium-ion batteries and lead-acid batteries as anode materials. It also plays a critical role as a carbon additive during the alloy preparation and casting processes.

- Our high temperature purification furnace employs advanced techniques to significantly increase the purity and crystallinity of special graphite, high carbon powder, and carbon felt insulation materials. The primary purpose of this high temperature graphite purification process is to effectively remove impurities and gases, thereby enhancing their physical and chemical properties to meet specific industrial and scientific application needs.

- In compliance with diverse customer requirements, we offer two heating methods and multiple discharge options for our high temperature purification furnace. Furthermore, we provide small batch sampling services and modifications for casting furnaces to accommodate high temperature purification processes.

- Utilizing this high temperature purification method, our furnace operates at 2850 °C to effectively eliminate impurities such as Mg, Al, Ca, Mn, Fe, and Ni from special graphite, achieving a carbon content of 99.5%. With prior processing and optimized protection gas techniques, alongside adjusted heating times at 3050 °C, we can elevate the carbon content to an astounding 99.9995%, with impurities below 5 ppm. Our expertise extends to managing boron content in graphite heated to 3000 °C, with levels maintained at less than 0.01 ppm, even without the introduction of fluorine or chlorine gases. This high performance has been validated through extensive industrial production of furnace models.

- Whether you are in research, analysis, or manufacturing, the High Carbon Powder High Purity Graphite High Temperature Purification Furnacesupplied from SINOWIN INDUSTRY is your best choice.Invest in our High Carbon Powder High Purity Graphite High Temperature Purification Furnace and leverage the technological advancements in material purity for your specialized applications.Donot hesitate to Contact us today for a quote and transform your scientific journey completely.

Main Features of our High Carbon Powder High Purity Graphite High Temperature Purification Furnace

- High Purity Production: The High Carbon Powder and High Purity Graphite High-Temperature Purification Furnace efficiently purifies materials by eliminating impurities and gases, achieving carbon purity levels of up to 99.9995% at 3050°C, making it ideal for specialized applications in semiconductor and battery manufacturing.

- Versatile Applications: Designed for various industries, our high-temperature purification furnace is used in the production of high-purity graphite crucibles, protective caps, heating elements, and more, catering to the needs of solar cell manufacturing and advanced materials industries.

- Advanced Heating Options: This purification furnace offers two different heating methods and multiple discharge options, tailored to meet customer requirements. It can also accommodate small batch sampling and conversion services for casting furnaces, ensuring flexibility in production.

- Exceptional Material Quality: By utilizing superior high-temperature processes, the furnace effectively removes contaminants such as Mg, Al, Ca, Mn, Fe, and Ni from specialty graphite, resulting in enhanced crystallinity and improved physical and chemical properties suitable for high-performance applications.

Technical Parameter:

| Work Size (mm) | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Volume(L) | 9 | 28 | 125 | 196 | 282 | 452 |

| Heating Power | 100 KW | 160 KW | 200 KW | 250 KW | 300 KW | 350 KW |

| Frequency | 2000 Hz | 2000 Hz | 2000 Hz | 1500 Hz | 1500 Hz | 1500 Hz |

| Max.Temperature | 3050°C | |||||

| Ultra Vacuum | 1.2×10-3 mbar | |||||

| Optional High Vacuum | 5×10-5 mbar | |||||

| Max.temperature rise rate | 15°C/min (RT~1500°C), 10°C/min (1500°C~2500°C), 5°C/min (2500°C~3000°C) | |||||

| Vacuum Pressure | 6.7×10-3 mbar/hr | |||||

| Atmosphere | High Vacuum(optional)/ Vacuum/ Inert Gas(Ar or N2)

Vacuum and high vacuum atmospheres are only allowed below 2200°C |

|||||

| Power | 3P, 380V, 50Hz/60Hz | |||||

| Pressure of the cooling water | 1.5~2.5 bar | |||||

| Water of the cooling water | ≤28 °C | |||||

Q&As for high-carbon powder and high-purity graphitization furnace, designed to be professional and conversion-friendly:

Q1: What is high-carbon powder, and how is it used in graphite production?

A1: High-carbon powder is a key raw material made from high-purity carbon sources that is essential in the production of graphite. It enhances the carbon content of the final product, helping to ensure superior quality and improved properties of graphite. By using high-carbon powder, manufacturers can achieve better conductivity, higher melting points, and improved overall performance of the graphite products.

Q2: How does a high-temperature purification furnace work?

A2: A high-temperature purification furnace functions by subjecting graphite materials to extreme heat in a controlled environment. This process eliminates impurities and enhances the crystal structure of graphite, resulting in higher purity levels. The furnace operates under precise temperature and atmospheric conditions, ensuring optimal purification and superior quality of the final graphite product.

Q3: What are the benefits of using high-purity graphite in industrial applications?

A3: High-purity graphite offers numerous benefits in industrial applications, including excellent electrical conductivity, superior thermal resistance, and reduced reactivity. These qualities make it indispensable in industries such as electronics, batteries, and aerospace. Additionally, using high-purity graphite can lead to enhanced product longevity and reliability, ensuring better performance in critical applications.

Q4: What methods are used to purify graphite to achieve high purity?

A4: Several methods are employed to purify graphite, including thermal treatment, chemical vapor deposition (CVD), and acid leaching. These processes effectively remove impurities from the graphite material, allowing manufacturers to achieve high purity levels, which are essential for various high-performance applications. Each method has its pros and cons, and the selection depends on the specific requirements of the final product.

Q5: How does high-carbon powder improve the properties of graphite?

A5: High-carbon powder enhances the physical and electrical properties of graphite by increasing its density, strength, and electrical conductivity. This improvement is especially important for applications in which durability and performance are critical. The addition of high-carbon powder ensures that the graphite produced can withstand demanding environments and perform consistently over time.

Q6: Which industries use high-temperature purification furnaces for graphite processing?

A6: High-temperature purification furnaces are utilized across various industries, including electronics, aerospace, automotive, and energy. These industries require high-purity graphite for applications such as semiconductors, battery components, and thermal management solutions. The ability to produce ultra-pure graphite makes these furnaces invaluable for manufacturers in high-tech sectors.

Q7: What factors should be considered when choosing a graphite purification furnace?

A7: When selecting a graphite purification furnace, several factors must be considered, including temperature range, capacity, energy efficiency, and control systems. Additionally, it’s important to assess the purifying method, the type of graphite being processed, and the desired purity levels to ensure the furnace meets specific production requirements and industry standards.

Q8: Why is high-purity graphite crucial for electrical applications?

A8: High-purity graphite is critical for electrical applications due to its exceptional conductivity and heat resistance. In components such as electrodes and contacts, even the slightest impurity can compromise performance and reliability. High-purity graphite ensures optimal electrical conductivity, reduces the risk of overheating, and improves overall efficiency, making it indispensable for high-performance electrical technologies.

Technical Parameter of the 3000°C high-carbon powder and high-purity graphitization furnace:

| Work Size (mm) | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Volume(L) | 9 | 28 | 125 | 196 | 282 | 452 |

| Heating Power | 100 KW | 160 KW | 200 KW | 250 KW | 300 KW | 350 KW |

| Frequency | 2000 Hz | 2000 Hz | 2000 Hz | 1500 Hz | 1500 Hz | 1500 Hz |

| Max.Temperature | 3050°C | |||||

| Ultra Vacuum | 1.2×10-3 mbar | |||||

| Optional High Vacuum | 5×10-5 mbar | |||||

| Max.temperature rise rate | 15°C/min (RT~1500°C), 10°C/min (1500°C~2500°C), 5°C/min (2500°C~3000°C) | |||||

| Vacuum Pressure | 6.7×10-3 mbar/hr | |||||

| Atmosphere | High Vacuum(optional)/ Vacuum/ Inert Gas(Ar or N2)

Vacuum and high vacuum atmospheres are only allowed below 2200°C |

|||||

| Power | 3P, 380V, 50Hz/60Hz | |||||

| Pressure of the cooling water | 1.5~2.5 bar | |||||

| Water of the cooling water | ≤28 °C | |||||