Product Description:

The Vacuum Graphite Pyrolysis Furnace is specifically designed for laboratory experimental and research environments, offering a compact structure, user-friendly operation, and a wide temperature range suitable for various applications.

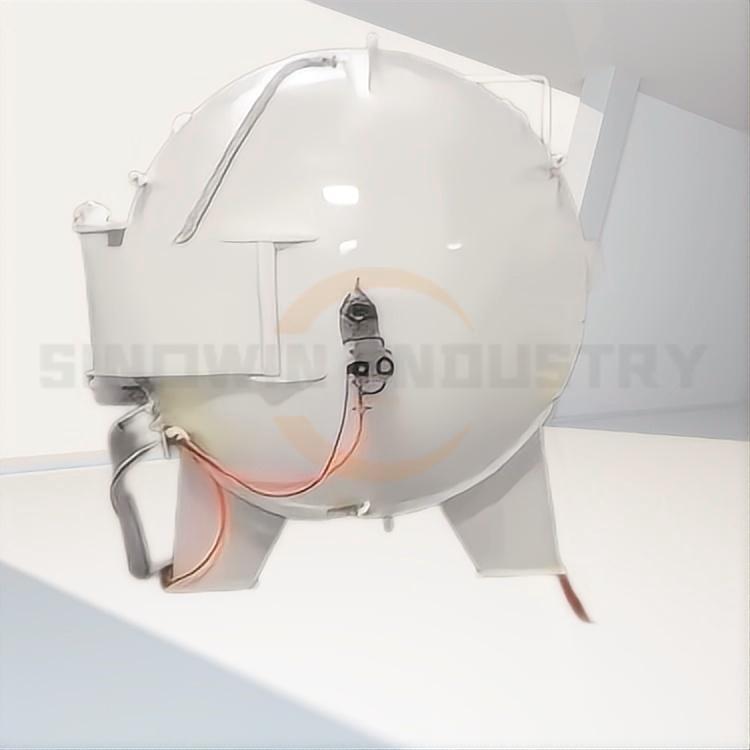

This innovative furnace features a cylindrical heating zone composed of a crucible, heating element, and furnace lining, all housed within a robust casing equipped with a water-cooling chamber. Its sleek design is particularly advantageous for experiments involving small samples in laboratory settings.

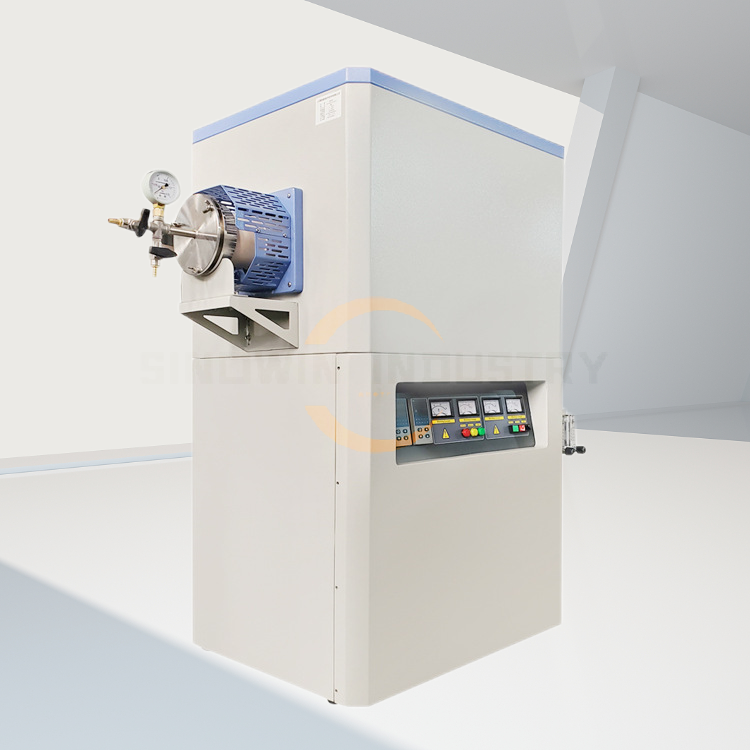

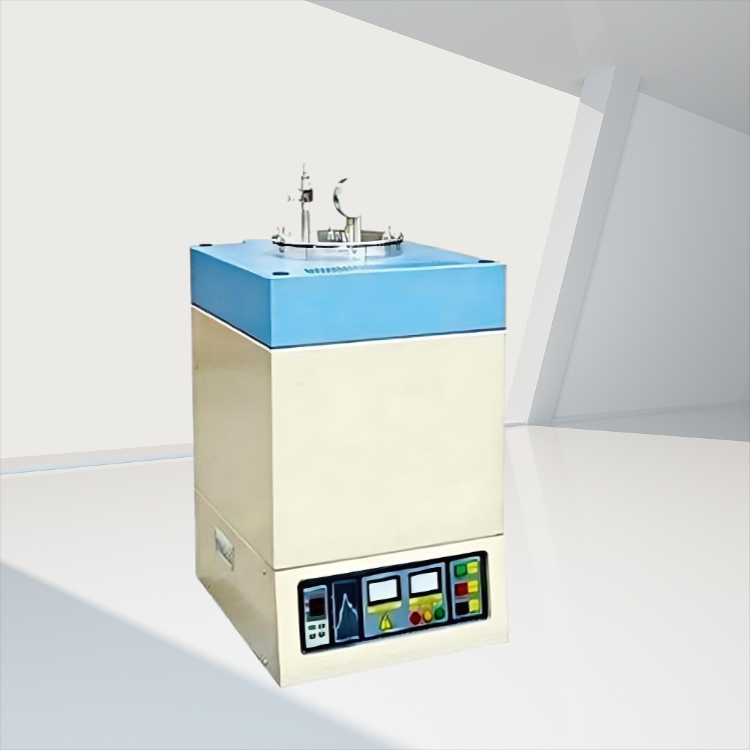

Crafted with precision and utilizing high-quality materials, the Vacuum Graphite Pyrolysis Furnace is engineered to reach heating temperatures of up to 2200°C under vacuum conditions, and even 3000°C in an argon atmosphere. The heating system consists of a temperature controller, power regulator, transformer, heating element, and thermocouple/pyrometer, allowing operators to easily set the desired heating program. The system functions in closed-loop format, with the temperature controller continuously adjusting power output to the heating element based on the temperature set point and actual temperature readings relayed by the thermocouple/pyrometer, ensuring accurate heating control.

Designed with a vacuum-sealed configuration, this furnace is equipped with a two-stage selection vacuum pump capable of achieving a vacuum level of 5×10^-2 mbar. The furnace body and control cabinet are mounted on a sturdy framework with wheels for effortless mobility.

For universities and industrial research institutions, the Vacuum Graphite Pyrolysis Furnace stands out as an exceptionally cost-effective tool with its minimal footprint, straightforward operation, broad heating temperature range, and excellent temperature uniformity. This makes it an ideal choice for high-performance pyrolysis applications.

Main Features of the 1350 degree Vacuum Graphite Pyrolysis Furnace

- Compact and Efficient Design: The Vacuum Graphite Pyrolysis Furnace boasts a space-saving cylindrical heating area, making it ideal for laboratory environments where small sample experiments are conducted. Its compact structure enhances accessibility and operational convenience.

- High-Temperature Capability: This state-of-the-art furnace features premium graphite heating elements and furnace linings that allow for heating under vacuum conditions up to 2200°C and in argon atmospheres up to an impressive 3000°C, catering to a wide range of experimental applications.

- Automated Temperature Control: Equipped with a closed-loop automatic heating control system including temperature controllers, power regulators, transformers, heating elements, and thermocouples, users can easily set desired heating programs for precise thermal management of samples.

- Advanced Vacuum System: Designed for optimal performance, the Vacuum Graphite Pyrolysis Furnace includes a high-efficiency two-stage rotary vacuum pump capable of achieving vacuum levels as low as 5×10^-2 mbar, ensuring minimal oxidation and contamination during high-temperature processes.

- User-Friendly Mobility and Support: Mounted on a sturdy stand with wheels for easy relocation, this furnace also features a control cabinet integrated into its design, providing a user-friendly setup that enhances the overall utility and practicality for universities and industrial research institutions.

Technical Parameter of the 1350 degree Vacuum Graphite Pyrolysis Furnace

| Working Zone | Ⅲm | 300*300*400 | 450+450*750 | 500*500*1200 | 500*500**1500 | 600*600*2000 | 750*750*2000 |

| Heating Method | / | Resistance Heating/IGBT Heating | |||||

| Volum | L | 36 | 151 | 300 | 375 | 720 | 1125 |

| Power | KW | 30 | 55 | 95 | 135 | 165 | 220 |

| Ultra Vacuum | Pa | 5×10^-2 mbar | |||||

| Working Temp. | ℃ | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Max. Temp. | ℃ | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 |

Q&A for Vacuum Graphite Pyrolysis Furnace

Q1: What is a vacuum graphite pyrolysis furnace and how does it work?

A1: A vacuum graphite pyrolysis furnace is a specialized industrial heating equipment designed for the thermal decomposition of carbon-based materials in a vacuum environment. The process involves heating the graphite material in the absence of oxygen, which prevents combustion. Instead, this controlled environment allows for the transformation of polymers or organic compounds into carbon-rich materials. By regulating temperature, vacuum levels, and heating rates, the furnace promotes the efficient conversion of feedstock into high-quality graphite, leading to excellent carbonization and material integrity.

Q2: What are the benefits of using a vacuum pyrolysis furnace for graphite processing?

A2: Utilizing a vacuum pyrolysis furnace for graphite processing offers numerous advantages. Firstly, the vacuum environment minimizes gas entrapment, preventing particle contamination and enhancing product purity. Secondly, it allows for thermal decomposition at lower temperatures compared to conventional methods, thus saving energy and reducing operational costs. Additionally, the ability to control heating rates and temperatures enables the production of high-quality graphite with consistent properties, essential for various industrial applications. Ultimately, this technology enhances the overall efficiency and sustainability of the graphite processing operation.

Q3: How can a vacuum pyrolysis furnace improve graphite production efficiency?

A3: A vacuum pyrolysis furnace significantly boosts graphite production efficiency through several mechanisms. It minimizes the time required for heating and carbonization by ensuring an optimal thermal profile, which accelerates reactions without compromising material quality. The absence of oxygen allows for the retention of more valuable carbon structures, thus increasing yield. Furthermore, advanced control systems in these furnaces enable real-time monitoring, allowing operators to fine-tune settings for maximum throughput. This combination of factors leads to a smoother workflow, reduced waste, and overall higher productivity in the graphite manufacturing process.

Q4: What is the maximum temperature that the vacuum graphite cracking furnace can achieve?

A4: The vacuum graphite cracking furnace can reach a maximum temperature of 2200°C under vacuum conditions. In an argon atmosphere, it is capable of achieving temperatures up to 3000°C, allowing for versatile applications in materials processing and research.

Q5: How does the heating control system work in this furnace?

A5: The heating control system is designed for precision and efficiency. It consists of a temperature controller, power regulator, transformer, heating elements, and thermocouples/high-temperature gauges. The operator sets the desired heating program, and the system automatically adjusts the power output based on the defined temperature set points and actual temperatures, ensuring reliable closed-loop controlled heating of the samples.

Q6: Is this furnace capable of operating under vacuum conditions?

A6: Yes, the furnace features a vacuum-sealed design complemented by a sophisticated two-stage selection vacuum pump, achieving a vacuum level of 5×10^-2 mbar. This allows for high-performance heating in controlled environments, essential for specialized applications in laboratories and industry.

Q7: What materials are used in the construction of the furnace?

A7: The furnace is constructed using high-grade materials, including high-spec graphite heating elements and graphite furnace lining materials. This enhances the durability and performance of the furnace, ensuring it effectively withstands extreme temperatures and conditions during operation.

Q8: Can I customize the heating program for different applications?

A8: Absolutely! The heating control system allows operators to easily set and customize heating programs according to their specific application needs. This flexibility makes the furnace suitable for various processes, from research and development to industrial uses.

Q9: What safety features are integrated into the vacuum graphite cracking furnace?

A9: The furnace is designed with safety as a priority. It includes multiple safety mechanisms such as thermal overload protection, emergency shut-off controls, and robust vacuum seals to prevent leaks. Additionally, regular maintenance and adherence to operational guidelines ensure safe and efficient usage of the equipment.

Q10: What types of applications is this furnace best suited for?

A10: This vacuum graphite cracking furnace is ideal for a wide range of applications, including materials synthesis, sample preparation, heat treatment, and research in areas like semiconductor production, aerospace materials, and nanotechnology. Its high-temperature capabilities and controlled environment make it a versatile tool for professionals in various fields.

Technical Parameter of the 1350 degree Vacuum Graphite Pyrolysis Furnace

| Working Zone | Ⅲm | 300*300*400 | 450+450*750 | 500*500*1200 | 500*500**1500 | 600*600*2000 | 750*750*2000 |

| Heating Method | / | Resistance Heating/IGBT Heating | |||||

| Volum | L | 36 | 151 | 300 | 375 | 720 | 1125 |

| Power | KW | 30 | 55 | 95 | 135 | 165 | 220 |

| Ultra Vacuum | Pa | 5×10^-2 mbar | |||||

| Working Temp. | ℃ | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Max. Temp. | ℃ | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 |