Product Description:

Application:

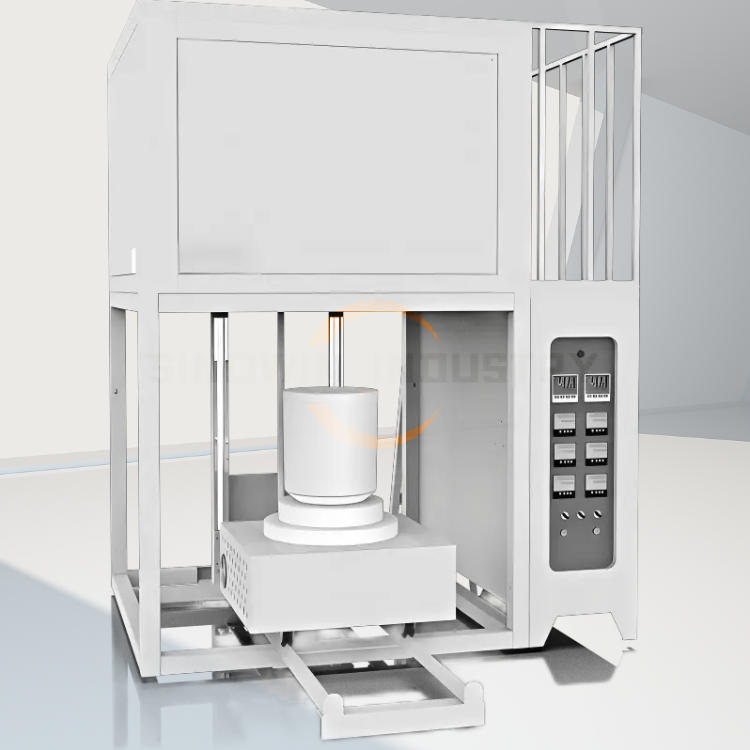

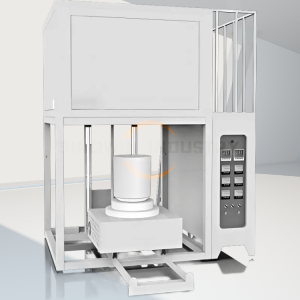

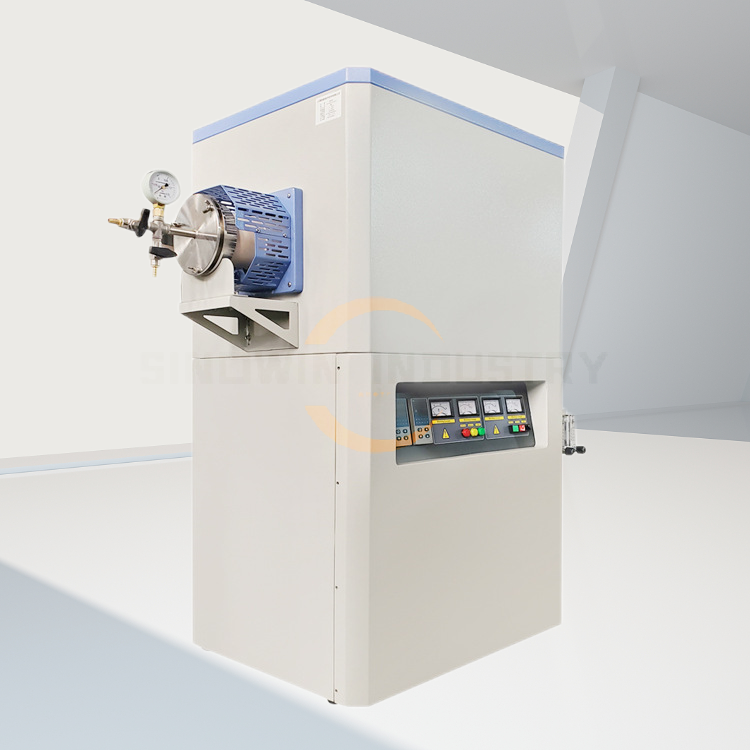

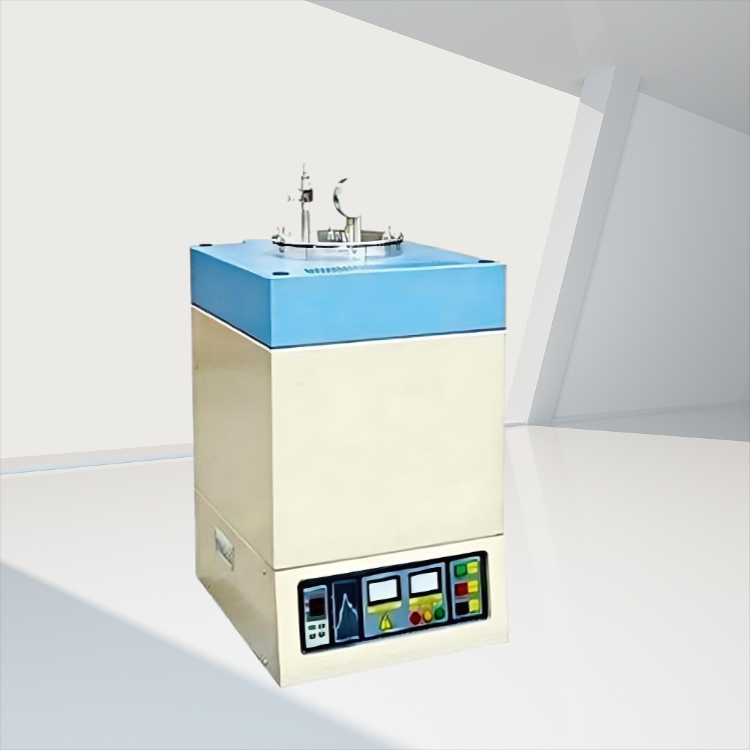

The High-Temperature Ceramic Frit Electrical Melting Furnace is designed and produced by sinowin industry for universities, research institutions, industrial enterprises, and laboratories engaging in high-temperature applications such as sintering, metal annealing, chemical processing, metallurgy, ceramics, glass products, new material development, organic matter ashing, and quality testing. This melting furnace is also suitable for military industry, electronics, pharmaceuticals, and specialty material production and experimentation.

Structure:

Crafted with a sensible double-layer casing structure, the surface temperature remains at or below 40℃, ensuring safety and efficiency. The exterior is both aesthetically pleasing and robust, constructed from cold-rolled steel plates, processed using CNC machining, high-precision laser cutting, and CNC bending techniques. The surface finish employs a sophisticated two-tone oxidized powder coat, resulting in a durable, fade-resistant, high-temperature, and corrosion-resistant treatment.

Heating Elements:

Choose from various heating elements based on furnace temperature requirements, including electric heating wire, resistance bands, silicon carbide rods, silicon molybdenum rods, and molybdenum wires.

Inner Lining Material:

The inner liner is made of imported high-purity light-weight alumina ceramic material, crafted through advanced techniques. It exhibits strong thermal shock resistance, excellent corrosion resistance, and remains free from collapse, crystallization, or residue, ensuring a long lifespan.

Temperature Control Method:

Featuring microcomputer intelligent adjustment technology, our melting furnace employs PID regulation with fully automatic control and self-calibration functionality. Multiple program segments allow for the management of various heating, insulation, and cooling cycles, alongside power regulation, ensuring high temperature control accuracy. The integrated module includes silicone-controlled and phase-triggered systems, complemented by independent protection mechanisms against overheating, overpressure, overcurrent, leakage, and short circuits, offering high levels of automation with industry-standard performance indicators.

Technical Parameters:

| Product | High-Temperature Ceramic Frit Electrical Melting Furnace | |||||

| Item | Unit | SW-R | SW-R | SW-R | SW-R | SW-R |

| Crucible volume | L | 1.6L | 3L | 5L | 10L | 18L |

| Temperature category | ℃ | 1000℃.1200℃. 1400℃. 1600℃. 1700℃ | ||||

| Crucible material | High-purity zircon quartz (99.9%) | |||||

| Temperature control accuracy | ±1℃ | ±1℃ | ±1℃ | ±1℃ | ±1℃ | ±1℃ |

| Voltage / frequency | AC/Hc | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 |

| power | KW | 10 | 12 | 15 | 18 | 25 |

| heating element | According to the temperature, choose the resistance wire, silicon carbon rod, silicon molybdenum rod heating. | |||||

| heating rate | From 1℃ / h to 40℃ / min is adjustable | |||||

| Thermocouples model | Depending on temperature, K, S, B | |||||

| Installation position of the heating element | Install the crucible for heating on all sides | |||||

| Temperature control mode | Microcomputer intelligent adjustment technology, with PID adjustment, automatic control, self-setting function, multi-section programming, and can compile various heating, insulation, cooling procedures, high temperature control accuracy; integrated module silicon control control, phase shift trigger. | |||||

| protector | Independent over-temperature protection, over-pressure, leakage, leakage, short circuit and other protection. The degree of automation is relatively high, and all the indicators have reached the level. | |||||

| Furnace material | High purity alumina containing zirconium fiber board | |||||

| Cauldron removal method | According to the volume of the crucible, the lower part is removed, and the upper part is removed | |||||

| The feeding method | Upper feeding, lower feeding discharge. | |||||

| cooling-down method | Double-layer furnace shell, air-cooled | |||||

| Furnace temperature | ≤45℃ | |||||

| computer interface | RS485/RS232/USB | |||||

| Random spare parts | There are two sets of rods, one copy of manual and one certificate of qualification | |||||

| Scope and duration of the warranty | Electric furnace free warranty for one year, heating components do not warranty. | |||||

| Optional attachment | Paper recorder, paper recorder, computer LCD touch screen, man-machine picture, communication online function, multiple devices and one computer control, print and save data, to achieve simple and convenient operation, real-time can view and save data. | |||||

| We can provide all kinds of accessories of the frit furnace, crucible, crucible cover, crucible plug, crucible pliers, high temperature gloves, etc.all different sizes can be customized. | ||||||

Key Features:

- The furnace chamber is constructed from imported light-weight high-purity alumina ceramic, known for its high hardness, non-powdering at elevated temperatures, and compliance with industry standards during high-temperature sintering.

- The heating elements, utilizing resistance wire/silicon carbide rods/silicon molybdenum rods, can handle significant loads, ensuring stability, longevity, and excellent temperature uniformity.

- Our patented temperature control design accelerates heating rates while improving sintering efficiency by over three times compared to similarly sized industry counterparts.

- The intelligent temperature controller boasts high precision with minimal temperature fluctuation, incorporating temperature compensation and correction capabilities, with an accuracy of ±1℃ (third-party detection certificates available).

- Equipped with operational and stop indicator lights, easily identifying the melting furnace’s status.

- The double-layer casing, constructed from carbon steel plates, undergoes rust-resistant and high-temperature baking paint treatment for added durability.

- All electronic components are sourced from reputable brands such as Delixi, featuring reliable leakage protection.

- Over-temperature alarms immediately cut power, and automatic leakage protection ensures dependable operation.

- The microcomputer control system includes intelligent PID regulation, with a 30-segment programmable temperature curve, allowing for autonomous operation without monitoring (full automatic heating, cooling, and insulation).

- Our software enables connection with computers, facilitating remote control of single or multiple melting furnaces, real-time tracking, historical record management, and report output. A paperless recording device can be installed for data storage and output.

Experience the precision and reliability of the Melting Furnace—your ideal partner for high-temperature applications across various industries.

Please feel free to consult for any additional questions or specifics related to your requirements for the High-Temperature Ceramic Frit Electrical Melting Furnace! Whether you’re in the manufacturing sector or a research facility, we supply one guaranteed option for your heating treatment industry that combines cutting-edge technology with user-friendly operation. and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment

Technical Parameters of the High-Temperature Ceramic Frit Electrical Melting Furnace

| Product | High-Temperature Ceramic Frit Electrical Melting Furnace | |||||

| Item | Unit | SW-R | SW-R | SW-R | SW-R | SW-R |

| Crucible volume | L | 1.6L | 3L | 5L | 10L | 18L |

| Temperature category | ℃ | 1000℃.1200℃. 1400℃. 1600℃. 1700℃ | ||||

| Crucible material | High-purity zircon quartz (99.9%) | |||||

| Temperature control accuracy | ±1℃ | ±1℃ | ±1℃ | ±1℃ | ±1℃ | ±1℃ |

| Voltage / frequency | AC/Hc | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 |

| power | KW | 10 | 12 | 15 | 18 | 25 |

| heating element | According to the temperature, choose the resistance wire, silicon carbon rod, silicon molybdenum rod heating. | |||||

| heating rate | From 1℃ / h to 40℃ / min is adjustable | |||||

| Thermocouples model | Depending on temperature, K, S, B | |||||

| Installation position of the heating element | Install the crucible for heating on all sides | |||||

| Temperature control mode | Microcomputer intelligent adjustment technology, with PID adjustment, automatic control, self-setting function, multi-section programming, and can compile various heating, insulation, cooling procedures, high temperature control accuracy; integrated module silicon control control, phase shift trigger. | |||||

| protector | Independent over-temperature protection, over-pressure, leakage, leakage, short circuit and other protection. The degree of automation is relatively high, and all the indicators have reached the level. | |||||

| Furnace material | High purity alumina containing zirconium fiber board | |||||

| Cauldron removal method | According to the volume of the crucible, the lower part is removed, and the upper part is removed | |||||

| The feeding method | Upper feeding, lower feeding discharge. | |||||

| cooling-down method | Double-layer furnace shell, air-cooled | |||||

| Furnace temperature | ≤45℃ | |||||

| computer interface | RS485/RS232/USB | |||||

| Random spare parts | There are two sets of rods, one copy of manual and one certificate of qualification | |||||

| Scope and duration of the warranty | Electric furnace free warranty for one year, heating components do not warranty. | |||||

| Optional attachment | Paper recorder, paper recorder, computer LCD touch screen, man-machine picture, communication online function, multiple devices and one computer control, print and save data, to achieve simple and convenient operation, real-time can view and save data. | |||||

| We can provide all kinds of accessories of the frit furnace, crucible, crucible cover, crucible plug, crucible pliers, high temperature gloves, etc.all different sizes can be customized. | ||||||