Product Description:

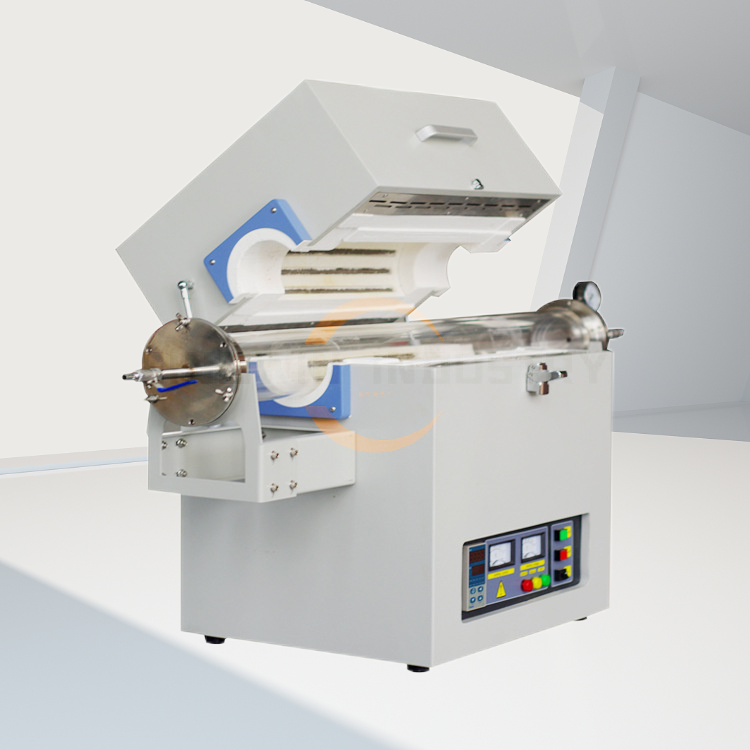

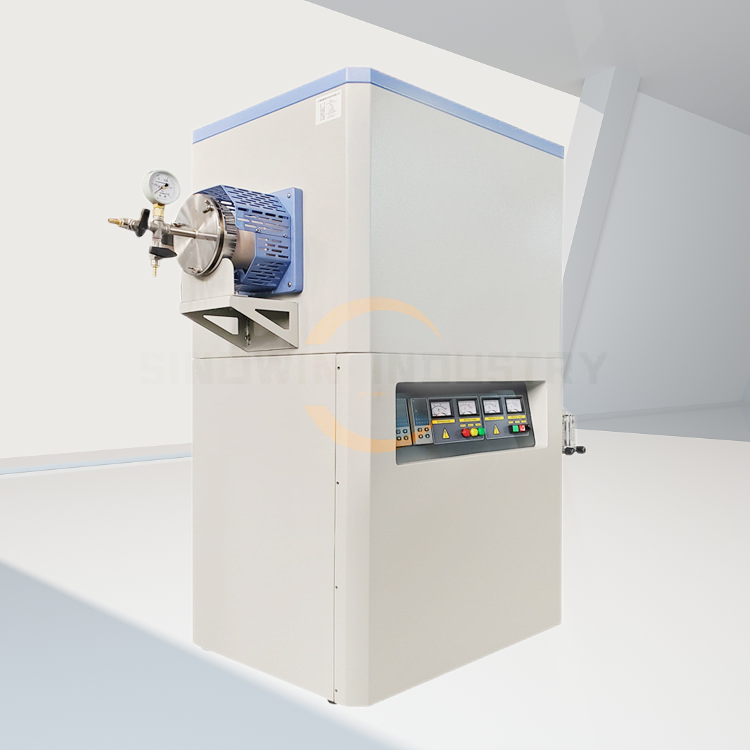

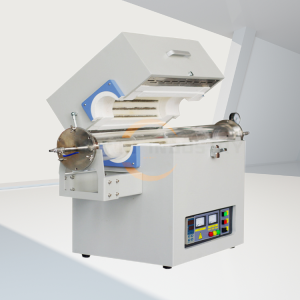

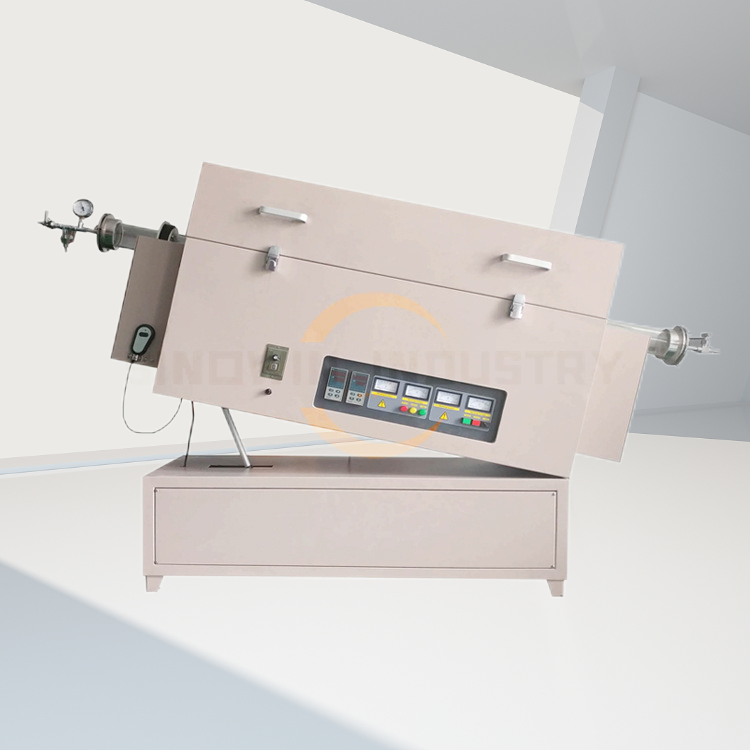

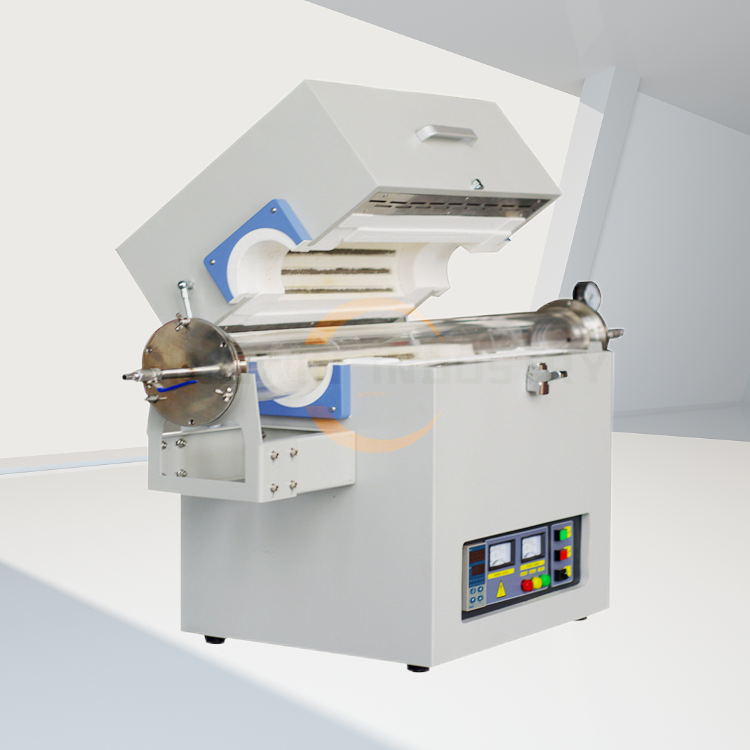

The High-Temperature Tube Furnace designed and produced by sinowin industry specifically for laboratory use, catering to the thermal treatment of samples in a vacuum or protective atmosphere. This furnace is ideal for various applications across ceramics, metallurgy, electronics, glass, chemical industries, machinery, refractory materials, specialty materials, construction materials, universities, research institutes, and mining enterprises, facilitating processes such as powder sintering, ceramic sintering, high-temperature experiments, material treatment, high-temperature atmosphere sintering, atmosphere reduction, CVD experiments, and vacuum annealing.

Product Overview:

The High-Temperature Tube Furnace features a robust double-layer shell structure, ensuring a surface temperature not exceeding 40°C. Constructed from cold-rolled steel plates with precision machining using CNC machine tools, laser cutting, and CNC bending machines, the surface is finished with dual-color oxidation powder through electrostatic spraying for enhanced durability.

Heating Elements: The furnace incorporates various heating elements based on operational temperature requirements, including electric wire, resistance bands, silicon carbide rods, silicon molybdenum rods, and molybdenum wires.

Inner Lining Material: The inner lining is crafted from imported high-temperature refractory materials, designed to withstand thermal shock, resist corrosion, remain non-collapsing, crystallize-free, and debris-free, ensuring a long service life.

Seal Design: The stainless steel flanges at both ends of the tube are sealed, enabling vacuum operations. These flanges are equipped with inlets and outlets for protective gases, featuring a quick-open design for easy material handling.

Product Features:

- The furnace chamber is insulated with imported alumina polycrystalline fiber, providing excellent thermal insulation, high tensile strength, free of impurities, and significant energy savings, all compliant with industry standards.

- The heating element is designed to endure high loads, providing stability and longevity, with a copper-isolated transformer ensuring uniform temperature distribution.

- Tube materials include quartz, corundum, alloy, or stainless steel, adaptable based on temperature, capable of accommodating various protective atmospheres.

- High temperature control precision with minimal temperature fluctuation, including temperature compensation and calibration functions, achieving a control accuracy of ±1°C.

- Utilizes imported temperature control instruments with programmability, allowing the setting of heating curves with up to 50 programmable segments.

- Aesthetic and functional design with an integrated structure, featuring a double-layer outer shell that promotes air circulation for thermal insulation.

- All electronic components are of premium quality, equipped with leakage protection for enhanced reliability.

- The machine issues alarm signals for overheating during operation and executes automatic protection measures to ensure safety.

- Once the program is set, simply press the run button, and the furnace will complete the subsequent operations automatically.

- User-friendly, programmable features include PID self-tuning, automatic heating, maintenance, and cooling without the need for supervision. It can additionally connect with computers for remote operation (start/stop the furnace, pause heating, set heating curves, store temperature histories, etc.).

- Stainless steel KF metal flange sealing (dual O-rings).

- The furnace body maintains a temperature close to room temperature for safety.

- Achievable vacuum level of -0.1Mpa (custom options available for specific vacuum requirements).

- Capable of using various gases (oxygen, nitrogen, argon, hydrogen, etc.), with customization options available.

- Temperature ranges available: 600°C, 800°C, 1000°C, 1200°C, 1400°C, 1600°C, 1700°C, and 1800°C.

Elevate your material processing capabilities with our High-Temperature Tube Furnace, the ultimate solution for precision thermal treatment in scientific and industrial applications.

Technical parameter of the High Temperature Tube Furnace

| Product | High Temperature Tube Furnace |

| voltage V | 220V/380V |

| design temperature | 600℃,800℃,1000℃,1200℃,1400℃,1600℃,1700℃,1800℃ |

| heating element | Using resistance wire, U-type silicon carbon rod, U-silicon molybdenum rod, (depending on temperature) |

| Temperature control accuracy | ± 1 degree (integrated circuit control, no overshoot) |

| The control range is | 0 / / 1800 degrees |

| Temperature measurement element | K-type Thermocouples (0-1250℃) / S Thermocouples (0-1600℃) / B Thermocouples (0-1800℃) (depending on temperature) |

| Furnace Tube material | Quartz / corundum / alloy / stainless steel tubes 310s (depending on temperature) |

| Flow-meter | Range: 0.3-3 L/min (is available upon request) |

| heating rate | 0-30℃ / min (heating rate can be freely adjustable) |

| vacuum degree | -0.1MPa, (1Pa,-1Pa,-0.01Pa etc) (customized to customer requirements) |

| Temperature control mode | Microcomputer program control function, can input setting: can input multiple curves at the same time, can be called arbitrarily when using |

| Furnace refractory | High purity alumina containing zirconium poly-crystalline fiber material |

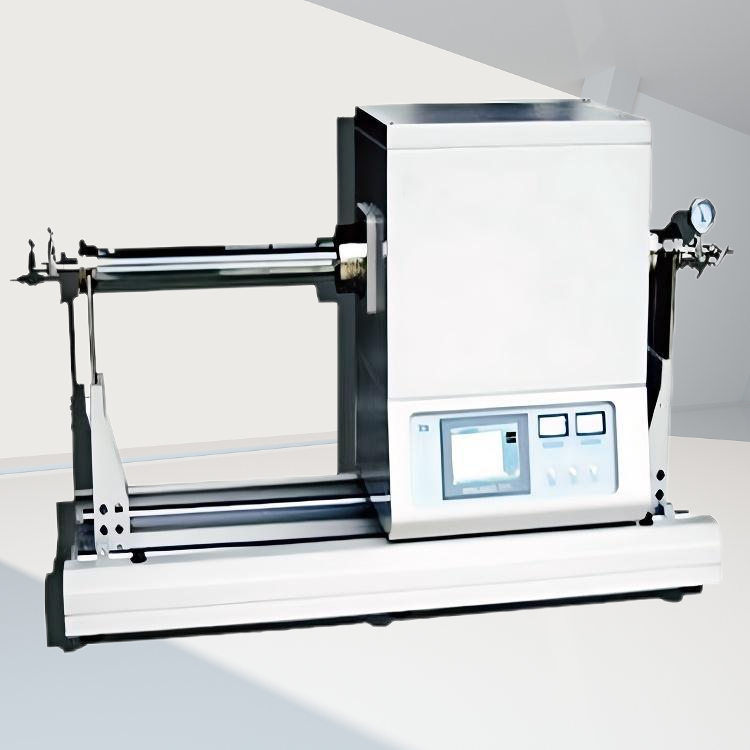

| rotational structure | The rotation speed is adjustable with a digital display governor, with an electric gear rotation system at one end and a bearing bracket at the other end |

| angle of inclination | Body tilt angle adjustable (0-30 degrees) (electric adjustable) |

| Furnace Tube speed | Furnace tube speed (0-10 rpm) / min (customized according to customer requirements) |

| tongued and grooved flanges | The instrument standard has a set of stainless steel sealing flanges, air outlet and inlet end are installed with rotary joint, stainless steel stop valve |

| Can pass gas | Nitrogen, argon, oxygen, hydrogen, ammonia, and other inert gases (can be customized according to customer requirements) |

| Scope and duration of the warranty | Electric furnace free warranty for one year, heating components, thermocouples do not warranty |

| Random spare parts | 2 heating components, 2 sets of rods, 1 furnace Tube, 2 sets of sealing flanges, 1 certificate, 1 pair of high temperature gloves. |

Ordering instruction:

Length (* * *) mm, tube diameter (* * *) mm, voltage selection (220V / 380V), temperature requirement (* * * * ℃), vacuum requirement (-0.1MPa- -10-6Pa)

Furnace tube size: the heating area and Tube diameter can be customized!

| Furnace tube diameter (mm) | Heating length (mm) | voltage AC | power (KW) | accuracy |

| 30、40、50、60、80、90、

100,110,120,150, etc |

150、250、300、400、500

600,700,1000,1200, etc |

220V/380V | 0.5-30KW | Control accuracy is ± 1℃ |

| Other furnace tube sizes can be customized according to customer requirements | ||||

Sinowin industry supply the indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with long-term trusted and reliable service.

Please feel free to consult for any additional questions or specifics about our High-Temperature Tube Furnace.

Technical parameter of the High Temperature Tube Furnace

| Product | High Temperature Tube Furnace |

| voltage V | 220V/380V |

| design temperature | 600℃,800℃,1000℃,1200℃,1400℃,1600℃,1700℃,1800℃ |

| heating element | Using resistance wire, U-type silicon carbon rod, U-silicon molybdenum rod, (depending on temperature) |

| Temperature control accuracy | ± 1 degree (integrated circuit control, no overshoot) |

| The control range is | 0 / / 1800 degrees |

| Temperature measurement element | K-type Thermocouples (0-1250℃) / S Thermocouples (0-1600℃) / B Thermocouples (0-1800℃) (depending on temperature) |

| Furnace Tube material | Quartz / corundum / alloy / stainless steel tubes 310s (depending on temperature) |

| Flow-meter | Range: 0.3-3 L/min (is available upon request) |

| heating rate | 0-30℃ / min (heating rate can be freely adjustable) |

| vacuum degree | -0.1MPa, (1Pa,-1Pa,-0.01Pa etc) (customized to customer requirements) |

| Temperature control mode | Microcomputer program control function, can input setting: can input multiple curves at the same time, can be called arbitrarily when using |

| Furnace refractory | High purity alumina containing zirconium poly-crystalline fiber material |

| rotational structure | The rotation speed is adjustable with a digital display governor, with an electric gear rotation system at one end and a bearing bracket at the other end |

| angle of inclination | Body tilt angle adjustable (0-30 degrees) (electric adjustable) |

| Furnace Tube speed | Furnace tube speed (0-10 rpm) / min (customized according to customer requirements) |

| tongued and grooved flanges | The instrument standard has a set of stainless steel sealing flanges, air outlet and inlet end are installed with rotary joint, stainless steel stop valve |

| Can pass gas | Nitrogen, argon, oxygen, hydrogen, ammonia, and other inert gases (can be customized according to customer requirements) |

| Scope and duration of the warranty | Electric furnace free warranty for one year, heating components, thermocouples do not warranty |

| Random spare parts | 2 heating components, 2 sets of rods, 1 furnace Tube, 2 sets of sealing flanges, 1 certificate, 1 pair of high temperature gloves. |