Product Description:

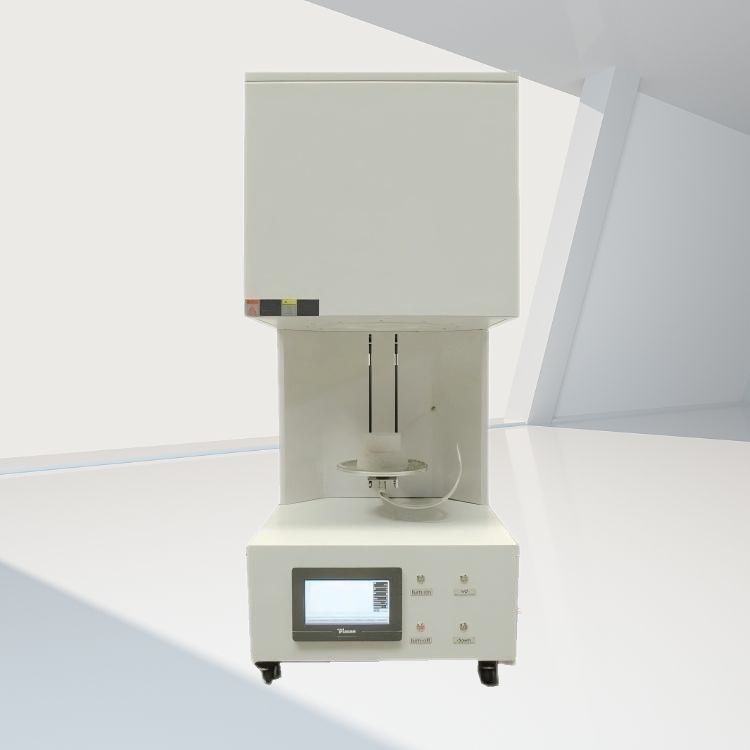

The High Temperature Vacuum rotary tube furnace is meticulously engineered for achieving superior consistency during the Sintering of inorganic compounds, making it an ideal choice for preparing conductive coating negative materials for lithium-ion batteries. This versatile equipment is suited for uniformly drying materials, calcining, and various high-temperature Sintering processes across a broad spectrum of applications, including ceramics, optical materials, composite materials, hard alloys, and powder metallurgy. It can also facilitate Sintering in a protected atmosphere.

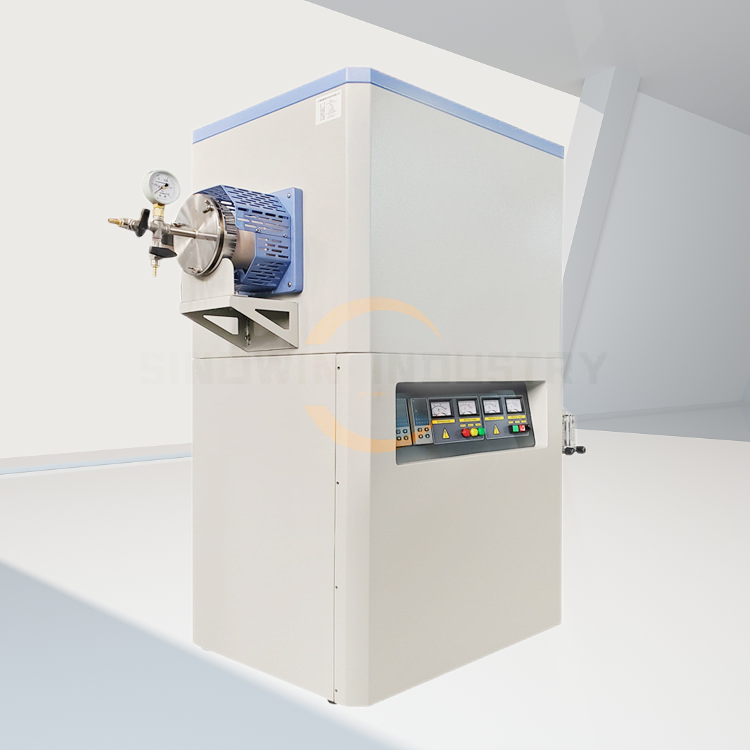

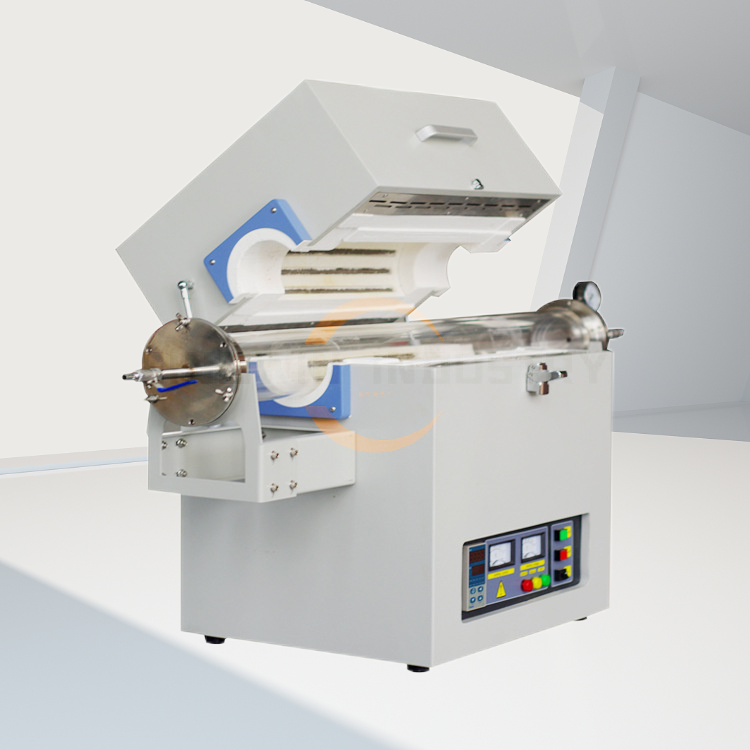

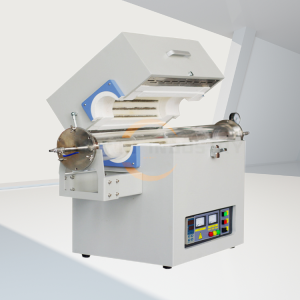

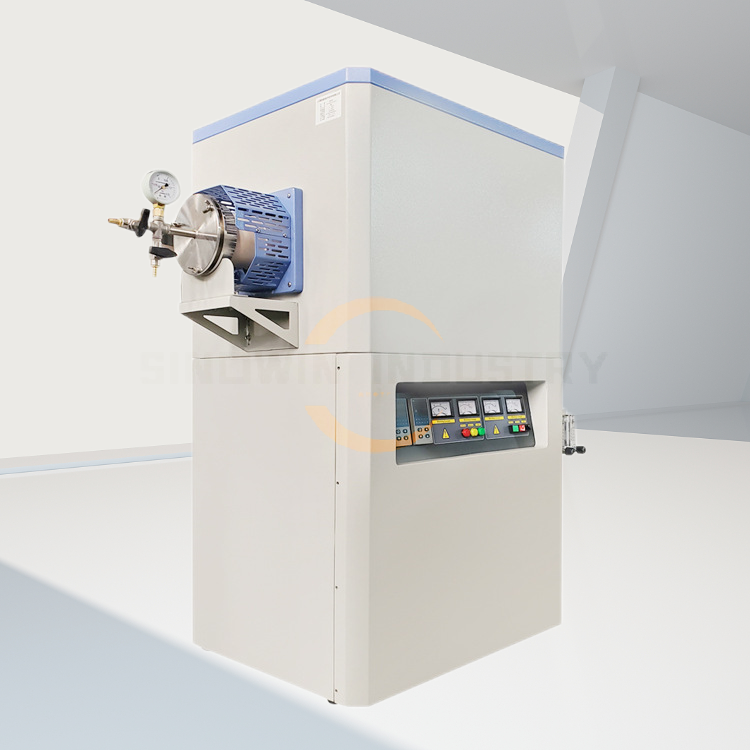

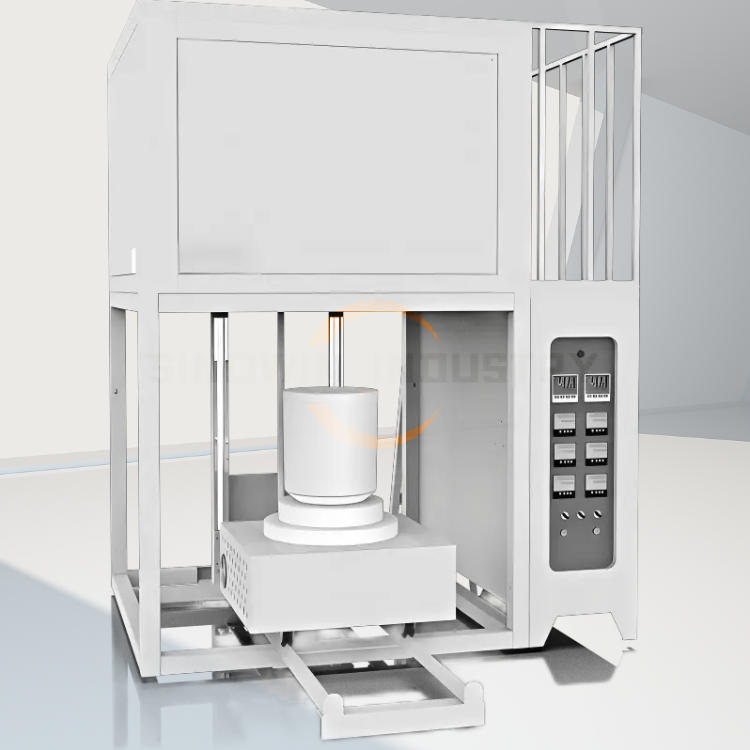

Designed with a furnace body that can tilt up to 30 degrees and a tube that can rotate a full 360 degrees, thisrotary tube furnace provides dynamic heating and ensures even distribution of heat. Furthermore, a dual temperature zone can be customized as needed. The adjustable rotation speed of the furnace tube, along with precise controls for temperature, heating time, and other parameters, allows for tailored experiments and production needs. The tube material options include heat-resistant alloys, quartz, and alumina, catering to diverse experimental setups.

Key Features:

- Intelligent 50-segment programmable automatic temperature control.

- Heating rate adjustable from 0 to 20°C/min.

- Temperature control accuracy of ±1°C.

- Top-opening design allows real-time observation of heated materials.

- Adjustable tilt angle of the furnace body from 0 to 30 degrees for easy loading and unloading.

- Tube rotation speed adjustable between 3 to 7 revolutions per minute, with the capability to reverse. The interior of the tube is equipped with three quartz lifting plates to ensure thorough material turnover and uniform heating during rotation.

- Safety features include door interlock system, over-temperature alarm, and leakage protection.

Advantage of the Rotary Tube Furnace

- High-Temperature Precision: The Rotary Tube Furnace is engineered for high-temperature vacuum Sintering, reaching temperatures of up to 1700℃, ensuring optimal performance and consistent results in the preparation of lithium-ion battery anode materials and various inorganic compounds.

- Versatile Application: This advanced Rotary Tube Furnace is ideal for a wide range of applications including material synthesis and Sintering, metal annealing, chemical reaction research, and the preparation of high-purity ceramics, composite materials, and superconductors.

- Intelligent Control System: Featuring a programmable automatic temperature control system capable of managing up to 50 segments and a heating rate of 0-20℃/min, the Rotary Tube Furnace provides high precision temperature control with an accuracy of ±1℃, facilitating meticulous experimental conditions.

- Dynamic Heating Mechanism: Designed for uniform heating, the Rotary Tube Furnace allows the furnace body to tilt up to 30 degrees and the tube to rotate between 3-7 RPM (with reverse capability), maximizing material exposure to thermal reactions and ensuring even heat distribution via integrated quartz lifting plates.

- Safety and Reliability: Equipped with essential safety features such as power interruption on door opening, over-temperature alarms, and leakage protection, this Rotary Tube Furnace ensures safe and reliable operation, making it suitable for demanding laboratory environments and industrial applications.

Specific Applications of the Rotary Tube Furnace:

- Material Synthesis and Sintering: Ideal for R&D of new materials, including metal powders, superconductors, ceramics, and composites.

- Battery Material Preparation:Optimally suited for laboratory calcination and drying of battery cathode materials like lithium iron phosphate, as well as non-strong acid and alkaline powder materials. The high-temperature environment and precise temperature control are pivotal in ensuring the performance and quality of battery materials.

- Metal Annealing and Sintering: Effective for the heat treatment of metal or alloy materials, enabling processes like annealing, tempering, and quenching to modify their micro structure and properties.

- Chemical Reaction Research:Frequently utilized for polymer synthesis, catalyst preparation, and various chemical reaction processes.

- Electronics Industry:Employed for high-temperature Sintering and chemical vapor deposition (CVD) processes involving materials such as graphite, sodium titanium phosphate, PSA molecular sieves, and carbon nanotubes.

Therotary tube furnace designed and manufactured by Sinowin Industry embodies safety, reliability, and user-friendly operation while maintaining remarkable heating precision and uniform thermal distribution, making it an invaluable asset in advanced materials research and industrial applications.

Parameters of the Rotary Tube Furnace:

| Product Name | Rotary Tube Furnace | ||

| Maximum Temperature | 1200℃ | 1400℃ | 1700℃ |

| Working Temperature | ≤1100℃ | ≤1300℃ | ≤1600℃ |

| Heating Element | resistance wire | Sic Heater | Mosi2 |

| Thermocouples | K type | S type | B type |

| Furnace pipe material | Quartz tube | Alumina tube | Alumina tube |

| External diameter of furnace pipe | φ50~φ150mm | φ50~φ100mm | φ50~φ100mm |

| Length of heating area | 200~450mm | 300~450mm | 300~450mm |

| Temperature area quantity | Single temperature area / multiple temperature area, can be customized according to customer needs | ||

| Other specifications can be customized according to the customer’s needs | |||

| spin velocity | 3-7 rpm (adjustable speed) | ||

| angle of inclination | 0-30° (angle-adjustable) | ||

| Temperature control mode | PID control and self-setting adjustment, intelligent 30-segment programmable | ||

| Temperature control protection | Ultra-mild diseven protection function | ||

| heating rate | Recommended for 0 to 20 ° C/min | ||

| Temperature control accuracy | ±1℃ | ||

| Furnace material | High-purity alumina refractory fiber | ||

| Furnace structure | Carbon steel shell, double shell and equipped with air cooling system | ||

| Furnace structure | horizontal type | ||

| Furnace door opening method | Sealed / open type (optional) | ||

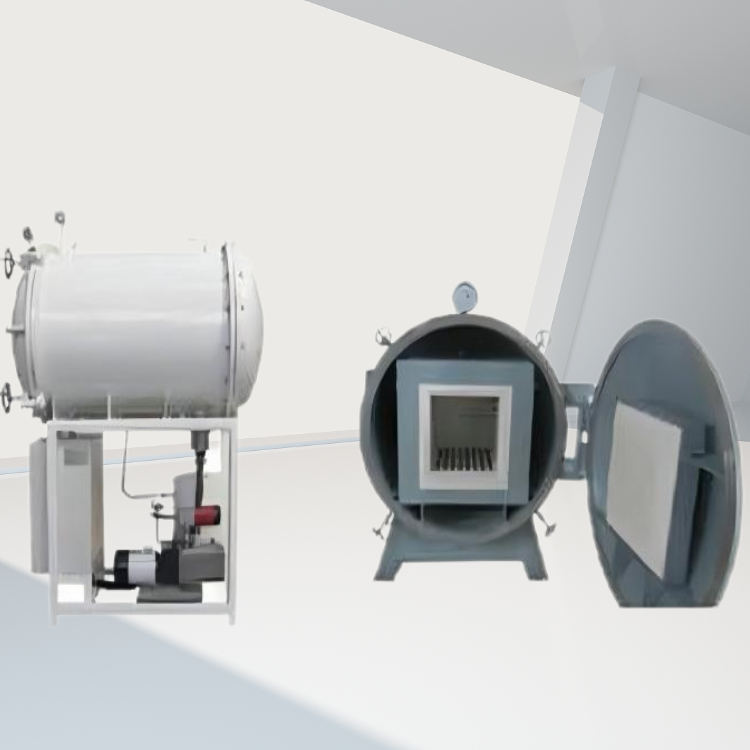

| work environment | Normal pressure / vacuum state / atmosphere state | ||

| working power supply | 220 / 380V, 50 HZ (customized to the requirements) | ||

| seal | Stainless steel vacuum flange, with a valve and a mechanical pressure gauge | ||

| Other optional configurations | Flow meter, vacuum system, open door power off, touch screen, remote control, computer display | ||

| Size (outer diameter of furnace pipe * length of heating area) | SNHT1200 | SNHT1400 | SNHT1700 |

| φ50*200mm

Φ60*300mm Φ60*450mm Φ80*300mm Φ80*450mm φ100*300mm φ100*450mm φ120*300mm φ120*450mm φ150*450mm |

φ50*300mm

φ80*300mm φ100*300mm φ100*450mm |

φ50*300mm

φ80*300mm φ100*300mm φ100*450mm |

|

| Other specifications of multi-temperature zone rotary tube furnace can be customized according to customer requirements | |||

Please feel free to send email to us if you have more questions or need further information about our High Temperature Vacuum Rotary Tube Furnace.!Sinowin Industry is not only a supplier but a reliable partner to assist you the safe solutions of the thermal treatment.

Parameters of the Rotary Tube Furnace:

| Product Name | Rotary Tube Furnace | ||

| Maximum Temperature | 1200℃ | 1400℃ | 1700℃ |

| Working Temperature | ≤1100℃ | ≤1300℃ | ≤1600℃ |

| Heating Element | resistance wire | Sic Heater

|

Mosi2

|

| Thermocouples | K type | S type | B type |

| Furnace pipe material | Quartz tube

|

Alumina tube

|

Alumina tube

|

| External diameter of furnace pipe | φ50~φ150mm | φ50~φ100mm | φ50~φ100mm |

| Length of heating area | 200~450mm | 300~450mm | 300~450mm |

| Temperature area quantity | Single temperature area / multiple temperature area, can be customized according to customer needs | ||

| Other specifications can be customized according to the customer’s needs | |||

| spin velocity | 3-7 rpm (adjustable speed) | ||

| angle of inclination | 0-30° (angle-adjustable) | ||

| Temperature control mode | PID control and self-setting adjustment, intelligent 30-segment programmable | ||

| Temperature control protection | Ultra-mild diseven protection function | ||

| heating rate | Recommended for 0 to 20 ° C/min | ||

| Temperature control accuracy | ±1℃ | ||

| Furnace material | High-purity alumina refractory fiber | ||

| Furnace structure | Carbon steel shell, double shell and equipped with air cooling system | ||

| Furnace structure | horizontal type | ||

| Furnace door opening method | Sealed / open type (optional) | ||

| work environment | Normal pressure / vacuum state / atmosphere state | ||

| working power supply | 220 / 380V, 50 HZ (customized to the requirements) | ||

| seal | Stainless steel vacuum flange, with a valve and a mechanical pressure gauge | ||

| Other optional configurations | Flow meter, vacuum system, open door power off, touch screen, remote control, computer display | ||

| Size (outer diameter of furnace pipe * length of heating area) | SNHT1200 | SNHT1400 | SNHT1700 |

| φ50*200mm

Φ60*300mm Φ60*450mm Φ80*300mm Φ80*450mm φ100*300mm φ100*450mm φ120*300mm φ120*450mm φ150*450mm |

φ50*300mm

φ80*300mm φ100*300mm φ100*450mm

|

φ50*300mm

φ80*300mm φ100*300mm φ100*450mm

|

|

| Other specifications of multi-temperature zone rotary tube furnace can be customized according to customer requirements | |||