Product Description:

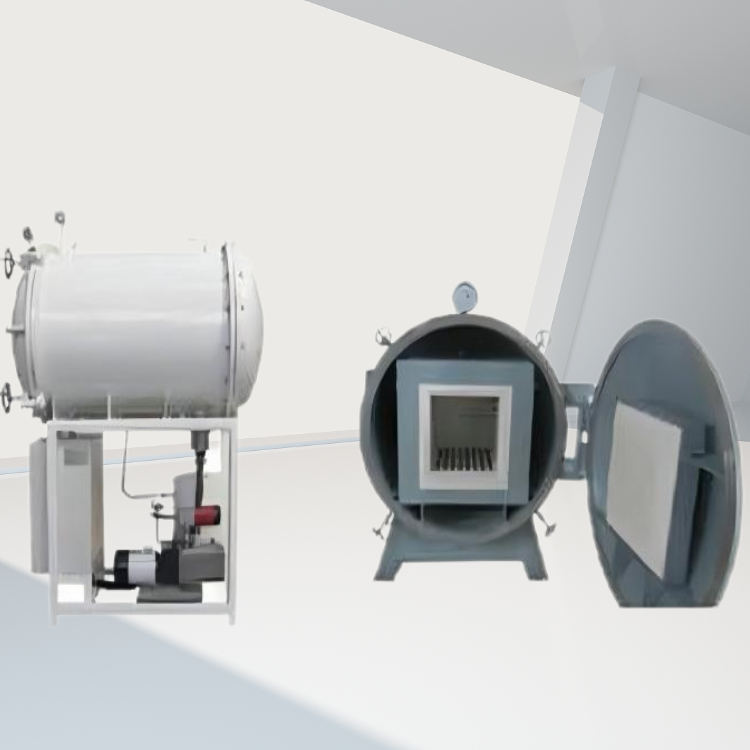

The High-Temperature Vacuum Tungsten Wire Sintering Furnace designed and produced by nanyang sinowin industry is a highly specialized vacuum resistance furnace that utilizes tungsten wire or tungsten mesh as the heating element. This sophisticated equipment is expertly designed for the sintering of various materials including metal compounds, ceramics, and inorganic compounds in a vacuum or protective atmosphere.

Ideal for high-temperature applications, the Vacuum Tungsten Wire Furnace plays a crucial role in processes involving the sintering of titanium, tantalum, and other refractory metal alloys, as well as advanced ceramic materials such as silicon carbide and silicon nitride. This furnace is also adept at facilitating the heat treatment of metallic materials under high vacuum conditions, ensuring optimal purification and properties enhancement.

Moreover, it is particularly beneficial for the degassing treatment of precious metal materials, making it an essential tool in both research and industrial settings. With its ability to deliver precise temperature control and a controlled environment, the Vacuum Tungsten Wire Furnace is the preferred choice for professionals seeking reliable results in high-temperature processing.

.

Applications:

Perfect for sintering of various ceramics, including transparent ceramics, as well as tungsten electrode processing. This furnace is also suitable for vacuum sintering of tungsten-molybdenum products.

Technical Parameter:

| Working Size | Rower(kw) | Working Temperature | Utmost Vacuum |

| Φ60×80㎜ | 18Kw | 2000℃ | 6.67×10-3Pa |

| Φ80×120㎜ | 30Kw | 2000℃ | 6.67×10-3Pa |

| Φ60×120㎜ | 50Kw | 2300℃ | 6.67×10-4Pa |

| Φ140×140㎜ | 45Kw | 2000℃ | 6.67×10-3Pa |

| Φ150×200㎜ | 50Kw | 2300℃ | 6.67×10-4Pa |

| Φ150×200㎜ | 50Kw | 2100℃ | 6.67×10-4Pa |

Technical Specifications:

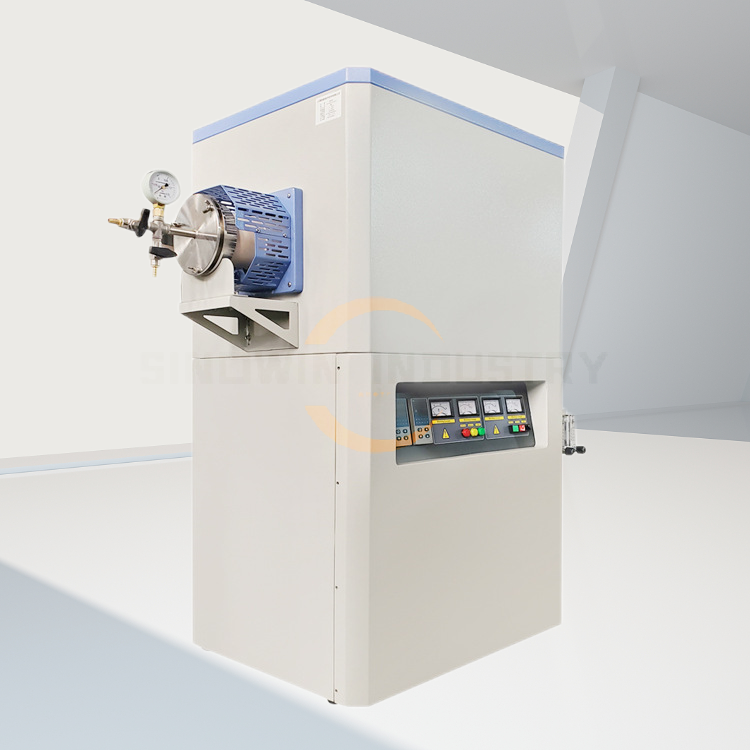

- Maximum Operating Temperature:2300°C

- Heating Method:Resistance heating

- Ultimate Vacuum:* 6.6710^-3 Pa

- Pressure Rise Rate:** <1 Pa/hour

- Protective Atmosphere:**Vacuum / Argon/Hydrogen

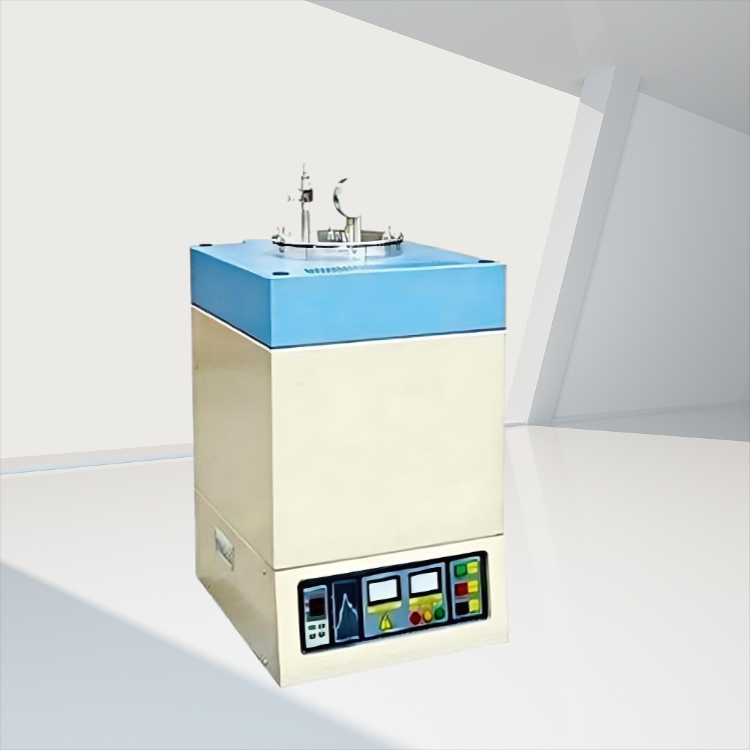

- Furnace structure:Vertical

- Bottom Discharge

High-Temperature Vacuum Tungsten Wire Sintering Furnace is engineered to meet the demands of high-performance applications in material science and semiconductor industries, guaranteeing superior results in your thermal processing needs.

Q1: What materials can the high-temperature vacuum tungsten wire furnace process?

A1: The high-temperature vacuum tungsten wire furnace is primarily designed for sintering and degassing treatments of ceramics, such as transparent ceramics, as well as tungsten electrodes. It is also suitable for the vacuum sintering of tungsten and molybdenum products. This versatility makes it ideal for a wide range of high-temperature applications.

Q2: What is the maximum working temperature of the High-Temperature Vacuum Tungsten Wire Furnace?

A2: The furnace can reach a maximum working temperature of 2300°C. This high-temperature capability allows for effective processing of materials that require precise thermal management and sintering under vacuum conditions.

Q3: What is the rated power and voltage of the High-Temperature Vacuum Tungsten Wire Furnace?

A3: The high-temperature vacuum tungsten wire furnace has a rated power of 40KW and operates at a rated voltage of 380V. These specifications ensure efficient operation and powerful heating capabilities essential for achieving high-performance results in material processing.

Q4: How does the High-Temperature Vacuum Tungsten Wire Furnace maintain the vacuum environment during operation?

A4: The furnace can achieve an extreme vacuum level of 5×10^-3 Pa, with a pressure increase rate of less than 1 Pa per hour. This exceptional vacuum control is crucial in preventing contamination during the sintering process and ensuring high-purity results.

Q5: What protective atmosphere is used in the High-Temperature Vacuum Tungsten Wire Furnace?

A5: The furnace operates in a protective atmosphere using argon or hydrogen gas. This controlled environment prevents oxidation and contamination of the materials being processed, ensuring high-quality outcomes in sintering and degassing treatments.

Q6: How can I ensure that my products are not contaminated during the sintering process?

A6: This furnace is specifically designed without carbon components, which significantly reduces the risk of carbon contamination. Additionally, by operating in a high vacuum and using an inert gas atmosphere (argon/hydrogen), we enhance the purity and integrity of your products during the sintering process.

Q7: Can this furnace be used for industrial applications?

A7: Yes, the high-temperature vacuum tungsten wire furnace is suitable for industrial applications, particularly in sectors that require precise material processing, such as aerospace, electronics, and advanced ceramics manufacturing. Its robust specifications and capabilities make it ideal for professional use.

Please feel free to consult for any additional questions or specifics related to your requirements for OUR Induction Silicon Carbide Sintering Furnace

!and Nanyang sinowin industry co.ltd are not only a lab and industrial furnace supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Technical Parameter of the High-Temperature Vacuum Tungsten Wire Sintering Furnace:

| Working Size | Rower(kw) | Working Temperature | Utmost Vacuum |

| Φ60×80㎜ | 18Kw | 2000℃ | 6.67×10-3Pa |

| Φ80×120㎜ | 30Kw | 2000℃ | 6.67×10-3Pa |

| Φ60×120㎜ | 50Kw | 2300℃ | 6.67×10-4Pa |

| Φ140×140㎜ | 45Kw | 2000℃ | 6.67×10-3Pa |

| Φ150×200㎜ | 50Kw | 2300℃ | 6.67×10-4Pa |

| Φ150×200㎜ | 50Kw | 2100℃ | 6.67×10-4Pa |

Technical Specifications of the High-Temperature Vacuum Tungsten Wire Sintering Furnace

- Maximum Operating Temperature:2300°C

- Heating Method:Resistance heating

- Ultimate Vacuum:* 6.6710^-3 Pa

- Pressure Rise Rate:** <1 Pa/hour

- Protective Atmosphere:**Vacuum / Argon/Hydrogen

- Furnace structure:Vertical

- Bottom Discharge