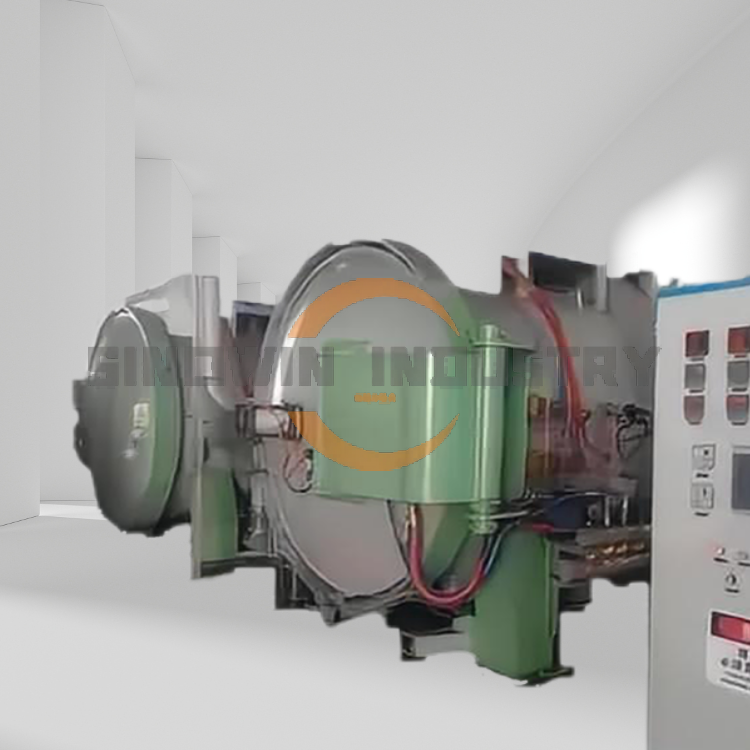

Product Description:

The High Thermal Conductivity Film Graphitization Furnace is an advanced manufacturing solution specifically for producing high-quality thermal conductive graphite films. it operates by applying controlled temperature profiles in an inert atmosphere, enabling the conversion of precursors into graphitized materials. The process enhances the material’s thermal conductivity, making it suitable for various high-performance applications.

Applications:

- Capable of producing diverse sizes and specifications of thermal conductive graphite films.

- Integrates seamlessly with upstream and downstream equipment, enhancing production efficacy significantly.

- Features microcomputer-controlled furnace distribution management for precise temperature control, recording, and monitoring of water, electricity, and gas data.

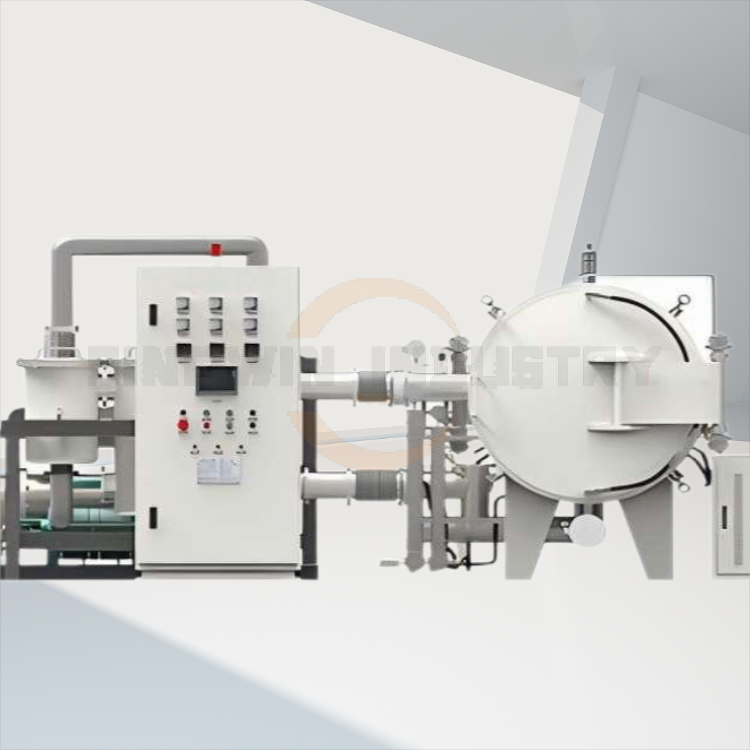

The High Thermal Conductivity Film Graphitization Furnace supplied by Sinowin Industry primarily comprises a carbonization furnace operating at temperatures between 1200-1600℃ and a high-temperature furnace ranging from 2800-3000℃, paired with essential systems such as gas purification units, filtration devices, and a recirculating cooling water system. This furnace not only supports the production of thermal conductive graphite films of various specifications but also guarantees the consistency and quality of each production batch.

Key Features:

- Fully Sealed Dustproof Power Cabinet: Designed to prevent conductive carbon fibers and dust from compromising electrical components, featuring built-in water cooling to avoid heat exchange with indoor air.

- Comprehensive PLC Control and Protection System: Ensures sequential control and interlocking protection for power supply, furnace body, cooling water, and protective gases, along with pre-warning and alarm functionalities.

- Closed Pure Water Recirculation System: Facilitates efficient cooling while displaying water flow rates on a touchscreen interface, utilizing stainless steel piping and deionized water for all water circulation.

- Gas Purification Unit: Capable of reducing oxygen content to 1 PPMV and achieving a dew point temperature lower than -80 degrees Celsius.

- Dual-Output Design: Enhances production capacity with both horizontal and vertical furnace configurations to meet varying product requirements.

Technical Parameter:

| Work Size | mm | Φ100*150 | Φ200*300 | Φ300*500 | Φ400*800 | Φ500*1000 | Φ600*1200 |

| IGBT Power | Kw | 60 | 120 | 160 | 200 | 250 | 400 |

| Frequency | Hz | 4000 | 2500 | 2500 | 1500 | 1500 | 1000 |

| Max.Temperature | C | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Ultra Vacuum | Pa | 1.2*107 | 1.2*10 | 1.2*107 | 1.2*107 | 1.2*10 | 1.2*107 |

| Temperature Uniformity | ℃ | ±10 | ±10 | ±10 | ±15 | ±15 | ±15 |

With the High Thermal Conductivity Film Graphitization Furnace, manufacturers can trust in a reliable, sophisticated, and efficient solution tailored to meet the demanding needs of thermal conductive graphite film production.Whether you are in research, analysis, or manufacturing, the Thermal Conductive Film Graphitization Furnace supplied from SINOWIN INDUSTRY is one guaranteed option for your heating treatment industry.

Donot hesitate to Contact us at once for any quotation of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Product Q&As for the Thermal Conductive Film Graphitization Furnace

● Q1: What is a Thermal Conductive Film Graphitization Furnace, and how does it work?

- A1: A Thermal Conductive Membrane Graphitization Furnace is a specialized device used for the heating and transformation of materials into a graphitic state. It operates by applying controlled temperature profiles in an inert atmosphere, enabling the conversion of precursors into graphitized materials. The process enhances the material’s thermal conductivity, making it suitable for various high-performance applications.

● Q2: What materials can be processed in the Graphitization Furnace?

- A2: The Graphitization Furnace is capable of processing a range of materials, including but not limited to carbon-based precursors, polymers, and certain composite materials. These materials undergo a transition into graphitic forms that significantly improve thermal properties.

● Q3: How does graphitization enhance thermal conductivity?

- A3: Graphitization enhances thermal conductivity by rearranging the carbon atoms into a highly ordered crystalline structure, which allows for efficient thermal energy transfer. This structural alignment reduces phonon scattering and enhances the overall heat conduction within the material, making it ideal for applications requiring high thermal performance.

● Q4: What are the benefits of using thermal conductive membranes in electronic applications?

- A4: The use of thermal conductive membranes in electronic applications offers numerous benefits, including improved heat dissipation, enhanced reliability of electronic components, and prolonged lifespan of devices. These membranes effectively manage thermal management challenges, ensuring optimal performance and preventing overheating.

● Q5: What factors should be considered when purchasing a Graphitization Furnace?

- A5: When purchasing a Graphitization Furnace, consider factors such as the maximum operating temperature, the size and capacity of the furnace, the type of heating mechanism (e.g., resistance or induction heating), inert gas capabilities, and compatibility with the materials you intend to process. Additionally, assess the manufacturer’s support and warranty options.

● Q6: How does the graphitization process improve material performance?

- A6: The graphitization process improves material performance by increasing thermal and electrical conductivity, enhancing mechanical strength, and providing better stability under high temperatures. This transformation allows materials to withstand more demanding environments, making them suitable for advanced applications in various industries.

● Q7: Which industries commonly utilize thermal conductive membranes and furnaces?

- A7: Thermal conductive membranes and furnaces are commonly utilized in industries such as electronics, aerospace, automotive, and energy sectors. They play a vital role in the development of components that require effective heat management solutions, such as heat sinks, batteries, and electronic devices.

● Q8: Can the Graphitization Furnace be used for small-scale production?

- A8: Yes, the Graphitization Furnace is suitable for small-scale production. It can be adapted for research and development purposes, as well as for the production of specialty materials in limited quantities. This flexibility makes it an excellent choice for laboratories or manufacturers looking to innovate without a large-scale commitment.

Technical Parameter of the 3000 degree High Thermal Conductivity Film Graphitization Furnace:

| Work Size | mm | Φ100*150 | Φ200*300 | Φ300*500 | Φ400*800 | Φ500*1000 | Φ600*1200 |

| IGBT Power | Kw | 60 | 120 | 160 | 200 | 250 | 400 |

| Frequency | Hz | 4000 | 2500 | 2500 | 1500 | 1500 | 1000 |

| Max.Temperature | C | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Ultra Vacuum | Pa | 1.2*107 | 1.2*10 | 1.2*107 | 1.2*107 | 1.2*10 | 1.2*107 |

| Temperature Uniformity | ℃ | ±10 | ±10 | ±10 | ±15 | ±15 | ±15 |