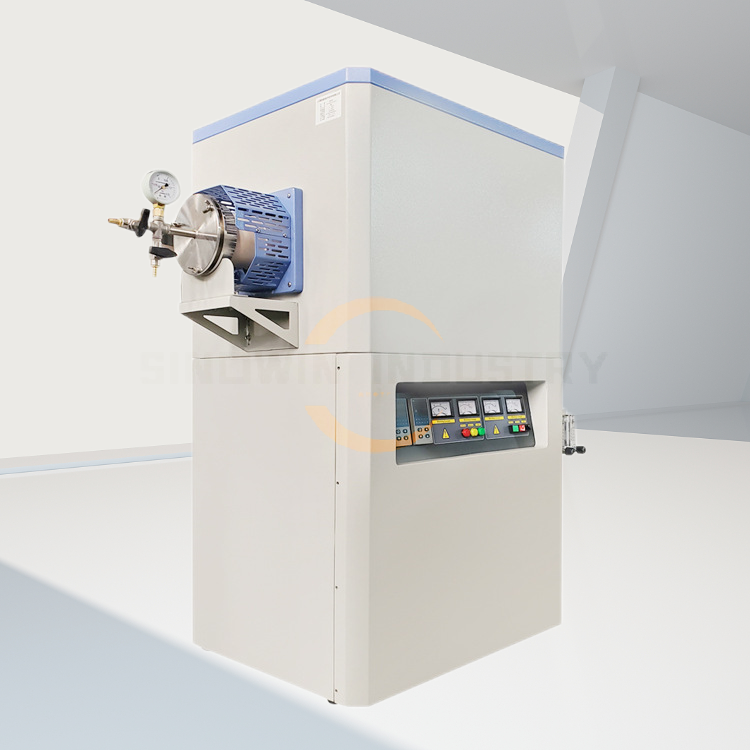

Product Description: High Vacuum High-Temperature Carbonization Furnace

The High Vacuum High-Temperature Carbonization Furnace is designed for the carbonization of various materials under controlled environments. This advanced furnace allows for high-temperature treatments in either a high vacuum or protective atmosphere, ensuring superior performance and dimensional stability of the finished products.

Product Characteristics:

- Maximum Design Temperature: Capable of reaching an impressive maximum design temperature of up to 2400℃, this furnace is engineered for optimal thermal efficiency.

- Long-term Operating Temperature: The furnace ensures reliable performance at a sustained operating temperature of 2200℃, catering to a broad range of carbonization applications.

- Spacious Charging Chamber: With a large charging space, this furnace enables easy loading and unloading of materials, significantly enhancing productivity.

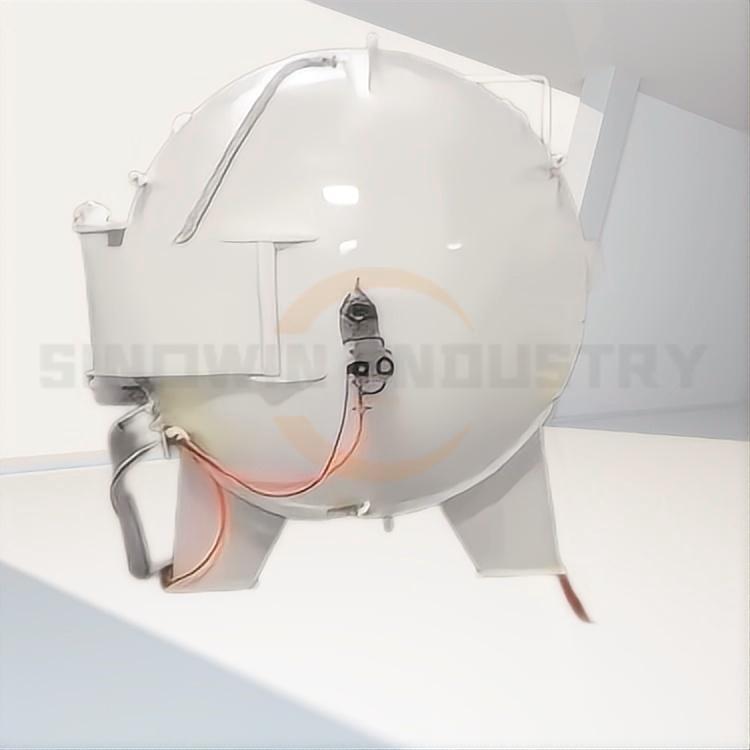

- Heating Method: Utilizing high-purity graphite heating elements, the furnace guarantees uniform heat distribution, thus minimizing thermal gradients during the carbonization process.

- Power Specification: Featuring multi-zone temperature control and operating at a voltage of less than 50V, this furnace provides precise and energy-efficient heating capabilities.

- Door Operation: The furnace is equipped with a hinge-driven electric rotating door system, facilitating seamless access to the chamber while ensuring safety and convenience.

- Loading Mechanism: The specialized material handling cart ensures efficient loading and unloading processes, further optimizing operational workflow.

- Working Atmosphere: The High Vacuum High-Temperature Carbonization Furnace operates effectively in either a high vacuum or a protective atmosphere, significantly enhancing the quality of the carbonized products.

Invest in the High Vacuum High-Temperature Carbonization Furnace for your advanced material processing needs. Designed for both efficiency and precision, this furnace is a reliable solution for achieving the highest standards in carbonization technology.

Technical parameter:

Parameter of the 2400 degree High Vacuum Carbonization Furnace

| W×H×L(mm) | 400×400×1000 | 600×600×1500 | 700×700×2000 | |||

| Ultra Vacuum(Pa) | 1X10-2 | 1X10-3 | 1X10-2 | 1X10-3 | 1X10-2 | 1X10-3 |

| Max temperature(℃) | 2400 | 2200 | 2400 | 2200 | 2400 | 2200 |

| Temperature Uniformity(℃) | ±7.5 | ±7.5 | ±7.5 | ±7.5 | ±7.5 | ±10 |

| Pressure rise rate(Pa/h) | 0.67 | 0.67 | 0.67 | |||

| Atmosphere | High Vacuum/Ar,N2 etc.,Inert atmosphere | |||||

| Heating Method | Resistance Heating | |||||

Parameter of the 1650 degree Vacuum Carbonization Furnace

| Work Size | Max.Temperature | Work Temperature | Voltage | Power | Ultra Vacuum | Temperature Uniformity | Atmosphere &Heating |

| mm | ℃ | ℃ | V | KW | Pa | ℃ | Vacuum/Ar,N2 etc.,

Inert atmosphere,Resistance heating |

| 800X800X1200 | 1650 | 1600 | 50 | 150 | 20 | ±10 | |

| 1000X1000X1500 | 1650 | 1600 | 50 | 210 | 20 | ±10 | |

| 1300X1300X2000 | 1650 | 1600 | 50 | 300 | 20 | ±15 | |

| 1500X1500X3000 | 1650 | 1600 | 50 | 550 | 20 | ±15 | |

| 1500X1500X3000 | 1650 | 1600 | 50 | 550 | 20 | ±15 | |

| 2500X2500X4000 | 1650 | 1600 | 50 | 1200 | 20 | ±15 | |

| 2500X2500X5000 | 1650 | 1600 | 50 | 1500 | 20 | ±15 |

Q&A for High Vacuum High Temperature Carbonization Furnace

- Q: What is the maximum temperature that this carbonization furnace can achieve?

- A: The maximum design temperature of our high vacuum high temperature carbonization furnace is an impressive 2400°C. This temperature allows for advanced material processing and high-performance carbonization.

- Q: What is the long-term operating temperature of the furnace?

- A: The furnace is engineered for long-term use at a consistent temperature of 2200°C, making it ideal for a variety of carbonization processes without compromising performance.

- Q: How convenient is the loading and unloading process with this furnace?

- A: Our furnace features a spacious loading area and employs a specialized charging system. This design ensures easy and efficient loading and unloading of materials, streamlining your workflow.

- Q: What type of heating element is used in this furnace?

- A: The furnace utilizes high-purity graphite heating elements, ensuring uniform heat distribution and enhancing the efficiency of the carbonization process.

- Q: How is the temperature controlled within the furnace?

- A: The furnace boasts multi-zone temperature control, allowing for precise adjustments and enhanced control of the heating process. It operates safely with a voltage of less than 50V.

- Q: Can the furnace door be opened easily during operation?

- A: Yes, the furnace door is designed with a hinge-type electric rotary mechanism, enabling smooth and effortless opening and closing during operation for optimal user convenience.

- Q: How is material loaded into the furnace?

- A: Materials are loaded into the furnace using a dedicated charging vehicle, ensuring safety and efficiency during the loading process.

- Q: What atmospheric conditions can this furnace operate under?

- A: The furnace can function in either high vacuum or protective atmosphere conditions, allowing for versatile processing based on the specific requirements of the materials being carbonized.

Whether you are in research, analysis, or manufacturing, the high vacuum high-temperature carbonization furnace supplied from SINOWIN INDUSTRY is your best choice.Please feel free to reach out if you have any further questions or require additional information regarding our high vacuum high temperature carbonization furnace!and donot hesitate to Contact us today for a quote and transform your scientific journey completely.

Parameter of the 2400 degree High Vacuum Carbonization Furnace

| W×H×L(mm) | 400×400×1000 | 600×600×1500 | 700×700×2000 | |||

| Ultra Vacuum(Pa) | 1X10-2 | 1X10-3 | 1X10-2 | 1X10-3 | 1X10-2 | 1X10-3 |

| Max temperature(℃) | 2400 | 2200 | 2400 | 2200 | 2400 | 2200 |

| Temperature Uniformity(℃) | ±7.5 | ±7.5 | ±7.5 | ±7.5 | ±7.5 | ±10 |

| Pressure rise rate(Pa/h) | 0.67 | 0.67 | 0.67 | |||

| Atmosphere | High Vacuum/Ar,N2 etc.,Inert atmosphere | |||||

| Heating Method | Resistance Heating | |||||

Parameter of the 1650 degree Vacuum Carbonization Furnace

| Work Size | Max.Temperature | Work Temperature | Voltage | Power | Ultra Vacuum | Temperature Uniformity | Atmosphere &Heating |

| mm | ℃ | ℃ | V | KW | Pa | ℃ | Vacuum/Ar,N2 etc.,

Inert atmosphere,Resistance heating |

| 800X800X1200 | 1650 | 1600 | 50 | 150 | 20 | ±10 | |

| 1000X1000X1500 | 1650 | 1600 | 50 | 210 | 20 | ±10 | |

| 1300X1300X2000 | 1650 | 1600 | 50 | 300 | 20 | ±15 | |

| 1500X1500X3000 | 1650 | 1600 | 50 | 550 | 20 | ±15 | |

| 1500X1500X3000 | 1650 | 1600 | 50 | 550 | 20 | ±15 | |

| 2500X2500X4000 | 1650 | 1600 | 50 | 1200 | 20 | ±15 | |

| 2500X2500X5000 | 1650 | 1600 | 50 | 1500 | 20 | ±15 |