Product Description:

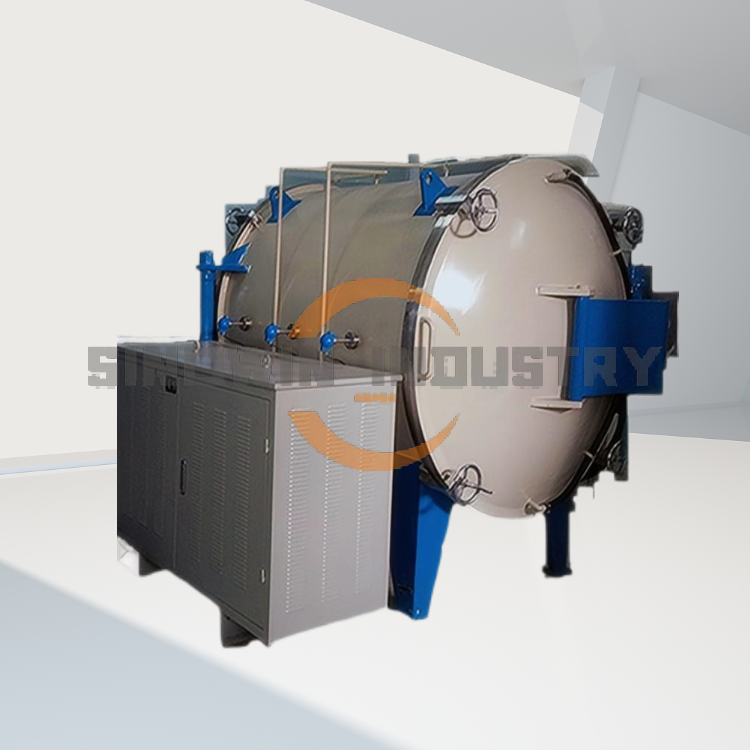

The Horizontal Vacuum High-Temperature Graphitization Furnace,used for a wide range of applications in the field of carbon materials, is ideal for the sintering and graphitization of carbon-based materials, including pi-film graphitization, thermally conductive material graphitization, carbon fiber rope sintering, and the graphitization of carbon fiber filaments. This furnace can accommodate various materials that can undergo graphitization in a carbon environment.

When utilized in tandem with its complementary carbonization furnace, the Horizontal Vacuum High-Temperature Graphitization Furnace significantly reduces labor and raw material costs while enhancing production capacity. It is particularly suitable for the production of roll materials and is instrumental in the manufacturing process of pi-films. The furnace also excels in high-temperature processing for graphite purification, phosphorus plate graphite, structural carbon products, C/C composite materials, carbon materials, and various other graphite material treatments.

Key Features:

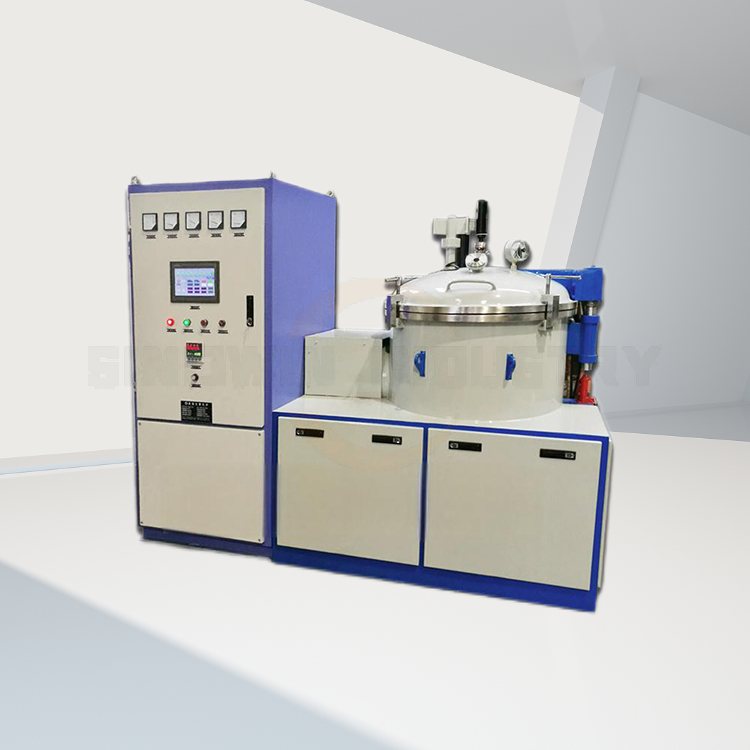

- Design and Structure: Our furnace features a circular, horizontal design with dual-opening doors and a single chamber structure. The high-temperature graphitization process is powered by medium-frequency induction heating. The furnace interior is equipped with a water-cooled induction coil, while an integrated graphite crucible serves as the induction current sensor surrounded by carbon felt as a thermal insulation material. The dual-layer water cooling system consists of a 304 stainless steel inner container and a cooling water jacket for temperature maintenance and safety.

- Operational Flexibility: The furnace is designed with a vacuum extraction interface, electrode flange, infrared temperature measurement ports, gas outlet, and an adjustable base height to accommodate different induction sensor requirements.

- User-Friendly Capabilities: The furnace cover operates using a manual hydraulic lift and swivel mechanism, offering more ergonomic handling compared to traditional manual wheel operations. Additionally, it is equipped with an observation port, temperature measurement port, and gas inlet to facilitate monitoring during operation.

- High-Quality Components: The induction coils are constructed with premium square copper tubing to minimize magnetic leakage while maximizing efficiency. Supporting arms for the sensors are made from stainless steel to prevent high-temperature degradation. Additionally, the resonant capacitors have a water-cooling structure with a 30% safety margin.

- Real-Time Temperature Monitoring: An imported infrared thermometer allows for real-time observation of the crucible temperature within the furnace. This advanced temperature sensing technology ensures accurate measurement even with smoke, dust, or particulate obstructions.

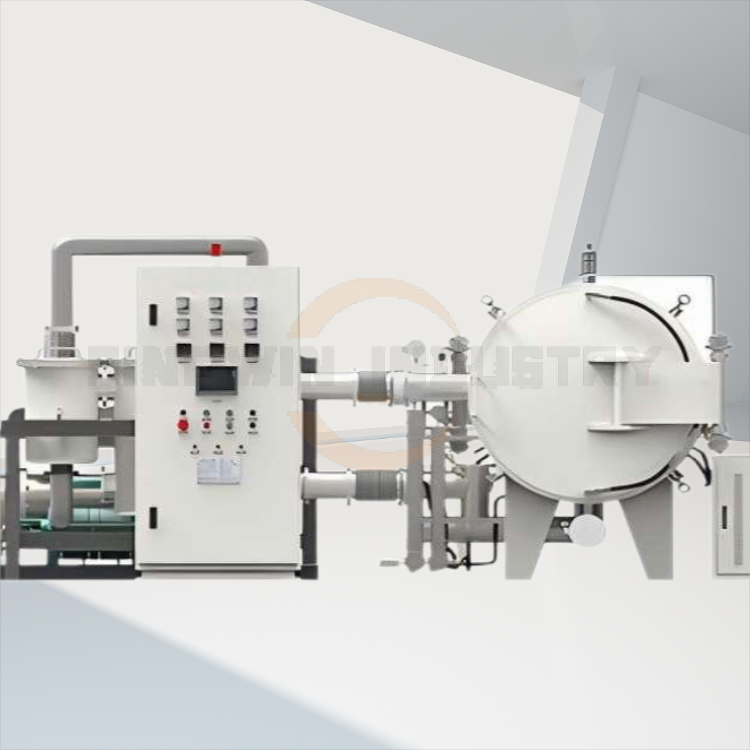

- Vacuum Acquisition System: The comprehensive vacuum system includes a direct-drive mechanical pump, electromagnetic vacuum valve for gas charging, vacuum butterfly valve, diaphragm valve, and connecting pipelines. It is equipped with a diaphragm vacuum valve for process gas charging and a second for reintroducing air before opening the furnace door.

- Intelligent Control System: The temperature control instrument employs a 0.1% class intelligent segmentation program to regulate heating cycles, with the capability to store up to 50 heating programs and optional communication ports. The system features PLC protection for monitoring conditions such as phase loss, water pressure, circuit status, protective gas levels, vacuum pump operation, furnace temperature, and control cabinet temperature. Moreover, it provides sequential control and interlocking protection for power, furnace body, cooling water, and protective gas systems. Alerts and alarms trigger for situations such as furnace body water temperatures exceeding 60 degrees, vacuum unit low-water conditions, and failure to achieve vacuum levels.

Advantage :

- High-Temperature Capability: The Horizontal Vacuum High-Temperature Graphitization Furnace boasts an impressive operating temperature of up to 3000℃, enabling efficient graphite purification tasks at a consistent temperature of 2800℃.

- Superior Sealing and Purity: Featuring a fully sealed structure combined with an advanced vacuum pumping and argon gas replacement system, this furnace ensures optimal gas purity within the chamber, thereby enhancing the overall quality of the graphitization process.

- Energy-Efficient Design: Utilizing electromagnetic induction heating directly on the graphite crucible, this furnace achieves high thermal efficiency while significantly reducing energy consumption, making it an environmentally friendly choice for industrial applications.

- Rapid Heating and Precision Control: With a high heating rate of up to 600℃/h and the use of advanced infrared temperature measurement technology, our PID segmented control system ensures precise temperature regulation with minimal error, guaranteeing consistent processing results.

- Enhanced Safety Features and User Convenience: Designed with a dual-layer stainless steel shell and water-cooled insulation, the furnace maintains exterior temperatures below 50℃, while integrated safety alarms for pressure, water, and high temperature provide peace of mind during operation. The horizontal design also simplifies loading, unloading, and maintenance, streamlining your workflow.

Technical Paremeter:

Round Furnace Chamber of the Horizontal Vacuum High-Temperature Graphitization Furnace

| Work Size(mm) | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Volume(L) | 9 | 28 | 125 | 196 | 282 | 452 |

| Heating Power | 100 KW | 160 KW | 200 KW | 250 KW | 300 KW | 350 KW |

| Frequency | 2000 Hz | 2000 Hz | 2000 Hz | 1500 Hz | 1500 Hz | 1500 Hz |

| Max.Working Temperature | 3000°C | |||||

| Temperature uniformity (between 1000°C and 2200°C) | ±10°C | |||||

| Ultra Vacuum | 1.2×10-3 mbar | |||||

Square Furnace Chamber of the Horizontal Vacuum High-Temperature Graphitization Furnace

| Work Size(mm) | 400X400X1200 | 500X500X1400 | 550X550X1600 |

| Volume (L) | 192 | 350 | 484 |

| Max.Working Temperature(℃) | 3000 | 3000 | 3000 |

| Power(KW) | 200 | 350 | 450 |

| Frequency(HZ) | 1500 | 1000 | 1000 |

| Heating Method | IGBT HEATING | ||

| Atmosphere |

High Vacuum(optional)/ Vacuum /N2,Ar or other inert gases |

||

Q&As for your Horizontal Vacuum High-Temperature Graphitization Furnace

Q1: What is the maximum operating temperature of the Horizontal Vacuum High-Temperature Graphitization Furnace?

A1: The Horizontal Vacuum High-Temperature Graphitization Furnace can reach a remarkable maximum operating temperature of up to 3000°C, making it highly suitable for graphite purification tasks. This capability ensures that it can effectively meet your high-temperature processing needs with precise temperature control.

Q2: How does the sealing system of the furnace maintain gas purity?

A2: Our furnace features a fully sealed structure equipped with a vacuum pumping system and an argon gas replacement system. This innovative design ensures optimal sealing, which significantly protects the purity of the internal gases during operation. You can trust this system to provide a controlled atmosphere essential for high-quality graphitization.

Q3: Can you explain the energy efficiency features of this furnace?

A3: Absolutely! The Horizontal Vacuum High-Temperature Graphitization Furnace utilizes electromagnetic induction heating, which directly heats the graphite crucibles. This method results in a high thermal efficiency, allowing for substantial energy savings. You’ll appreciate the cost-effectiveness of this furnace as it minimizes power consumption while maintaining excellent performance.

Q4: What is the heating rate and how does it influence the process?

A4: This furnace boasts an impressive heating rate of up to 600°C per hour, with even faster heating for lower temperature ranges. Such rapid heating contributes to increased productivity and reduced processing time, allowing your projects to progress efficiently without compromising on quality.

Q5: How is temperature controlled in the furnace, and why is it important?

A5: The furnace employs advanced infrared temperature measurement technology paired with PID segmented program control for the heating curve. This system ensures precise temperature management with minimal error margins. Accurate temperature control is critical in materials processing to achieve desired material properties and ensure consistent results.

Q6: What safety features does the furnace incorporate?

A6: Safety is a top priority for our Horizontal Vacuum High-Temperature Graphitization Furnace. It is designed with a double-layer stainless steel outer shell that features water cooling in the interlayer, keeping the exterior temperature below 50°C. Additionally, it includes pressure, water pressure, and high-temperature alarms, as well as an overpressure venting system to ensure safe operation at all times.

Whether you are in research, analysis, or manufacturing, the Horizontal Vacuum High-Temperature Graphitization Furnace supplied from SINOWIN INDUSTRY is your best choice.Donot hesitate to Contact us today for a quote and transform your scientific journey completely.

Technical Paremeter:

Round Furnace Chamber of the Horizontal Vacuum High-Temperature Graphitization Furnace

| Work Size(mm) | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Volume(L) | 9 | 28 | 125 | 196 | 282 | 452 |

| Heating Power | 100 KW | 160 KW | 200 KW | 250 KW | 300 KW | 350 KW |

| Frequency | 2000 Hz | 2000 Hz | 2000 Hz | 1500 Hz | 1500 Hz | 1500 Hz |

| Max.Working Temperature | 3000°C | |||||

| Temperature uniformity (between 1000°C and 2200°C) | ±10°C | |||||

| Ultra Vacuum | 1.2×10-3 mbar | |||||

Square Furnace Chamber of the Horizontal Vacuum High-Temperature Graphitization Furnace

| Work Size(mm) | 400X400X1200 | 500X500X1400 | 550X550X1600 |

| Volume (L) | 192 | 350 | 484 |

| Max.Working Temperature(℃) | 3000 | 3000 | 3000 |

| Power(KW) | 200 | 350 | 450 |

| Frequency(HZ) | 1500 | 1000 | 1000 |

| Heating Method | IGBT HEATING | ||

| Atmosphere |

High Vacuum(optional)/ Vacuum /N2,Ar or other inert gases |

||