Product Description:

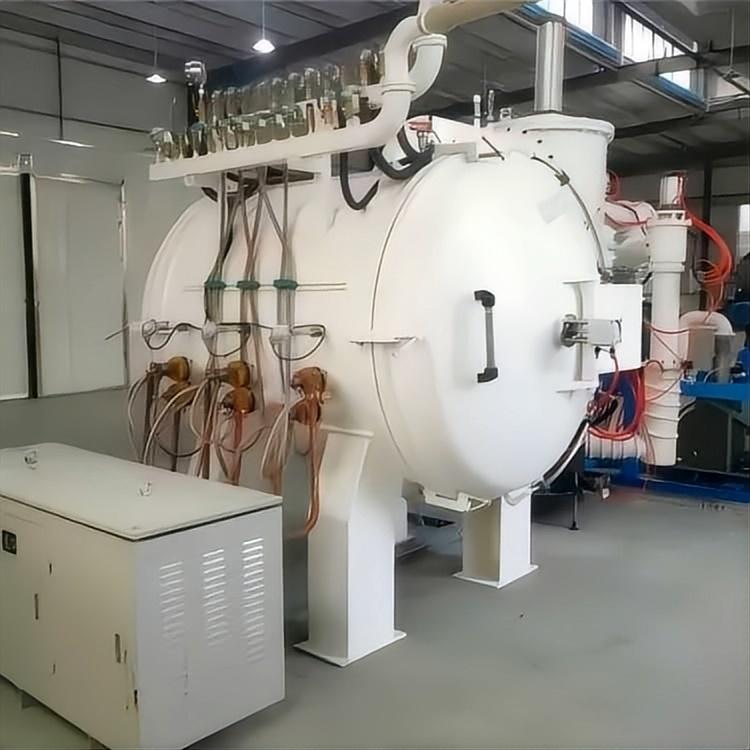

The Induction Sintering Furnace for Silicon Carbide, a heat treatment solution designed by sinowin industry specifically for the hard alloy and powder metallurgy industries, is specialized in producing silicon carbide powder of various particle sizes, sintering silicon carbide sealing ceramics, pressureless silicon carbide sintering, as well as titanium carbide and vanadium carbide powders, along with composite metal powders.

Key Features:

- High-Efficiency Electromagnetic Induction Heating:

The furnace employs electromagnetic induction heating that offers superior thermal efficiency and an extended lifespan for the heating elements. Unlike traditional graphite rod resistance heating furnaces, which suffer short operational life due to high temperatures and electrode insulation material limitations, our furnace ensures reliability and durability, avoiding frequent replacements.

- Stable Operation at Ultra-High Temperatures:

With a remarkable working temperature of up to 2300°C-2400°C, this furnace is compatible with a wide range of applications, fulfilling the stringent demands for silicon carbide powder, sealing ceramics, pressureless sintering, and various metallic and composite powders.

- Excellent Sealing and Versatile Operation:

Featuring a fully sealed structure with a vacuum pumping system and protective gas circulation, the furnace can operate under high vacuum conditions or in a protective gas atmosphere, meeting diverse product and process requirements.

- Cooling Filtration System:

Our innovative cooling filtration system effectively protects the vacuum environment, ensuring consistent performance.

- Rapid Cooling Design:

The integrated quick-cooling structure significantly reduces production cycles. The furnace is equipped with an inner door insulation layer and an external cooling gas circulation system, cutting down cooling times by over 50%.

- Precision Temperature Control:

Utilizing infrared temperature measurement technology, alongside PID segmented control of the heating curve, this furnace ensures precise temperature management with minimal deviation.

- User-Friendly Control Software:

The sintering furnace features intuitive software integrated into a human-machine interface, simplifying operations such as power on/off, alarm indications, temperature curve programming, display, recording, and data export. This design combining aesthetic appeal with practicality streamlines your operational workflow.

Whether you’re working with silicon carbide powders or other metallic and composite materials,, the Induction Sintering Furnace for Silicon Carbide produced by sinowin industry with unmatched efficiency and reliability is engineered to meet the highest industry standards.

Technical Parameters of Induction Silicon Carbide Sintering Furnace:

| Working Size-DX(mm) | 400X400X1200 | 500X500X1600 | 600X600X1600 | 700X700X4000 |

| Utmost temperature (℃) | 2450 | 2450 | 2450 | 2450 |

| Working Temperature(℃) | 2400 | 2400 | 2400 | 2400 |

| Temperature uniformity(℃) | ±10 | ±10 | ±10 | ±10 |

| Working Voltage(V) | 3 phase,380 | |||

| Rated Power(KW) | 160 | 200 | 250 | 400 |

| Ultimate Vacuum(pa) | 0.1 | 0.1 | 0.1 | 0.1 |

| The above technical parameters of the silicon carbide sintering furnace can be adjusted according to the process parameters, not as a basis for acceptance, and shall be implemented according to the specific technical plan and agreement shall be implemented | ||||

Silicon carbide performance index::

| Index name | Atmospheric pressure sintered silicon carbide | Reaction sintered silicon carbide | Plus carbon silicon carbide |

| Purity (%) Silicon carbide content | > 97 | >90 | carbon content30% |

| Density (g/cm) ) | 3.06-3.15 | >3.05 | >2.65 |

| Granularity (um) | 0.5-0.7 | 8-20 | 20-40 |

| Hardness ( | ≥90 | ≥90 | ≥85 |

| Flexural strength MPa) | 400-580 | 350-450 | 200 |

| Compressive strength(MPa) | 3900 | >2500 | 1800 |

| Elastic modulus(GPa) | 380-410 | 420 | |

| Elastic modulus(GPa) | 380-410 | 420 | |

| Thermal conductivity | 102.6 | 35-110 | 125 |

| Thermal expansion coefficient (1/℃) | 4.02×10 | 4.3×10 | 3×10 |

| Poisson’s ratio | 0.14 | 0.15 |

Q1: What is an induction silicon carbide sintering furnace?

A1: An induction silicon carbide sintering furnace is a specialized industrial device designed for the sintering process of silicon carbide (SiC) ceramics. The furnace utilizes induction heating technology, which means that it generates heat within the material itself, rather than relying on an external heat source. This allows for rapid and uniform heating, enabling the sintering of SiC at high temperatures. This process leads to the densification of the material, enhancing its mechanical strength, hardness, and thermal stability, making it ideal for various applications, including electronics, aerospace, and manufacturing.

Q2: How does an induction silicon carbide sintering furnace work?

A2: The induction silicon carbide sintering furnace operates using electromagnetic fields to induce an electric current within the silicon carbide material placed inside the furnace. This induces efficient heat generation due to the material’s resistance, causing it to reach the necessary sintering temperatures rapidly. The furnace is constructed with advanced insulation materials to maintain temperature consistency and to maximize energy efficiency. As the silicon carbide particles heat up and undergo sintering, they bond together, resulting in a solidified end product with superior physical properties. This innovative heating method not only shortens processing times but also enhances product quality.

Q3: What are the advantages of using an induction silicon carbide sintering furnace over traditional sintering methods?

A3: The induction silicon carbide sintering furnace offers several advantages compared to traditional sintering methods:

- Efficiency: It provides rapid heating and shorter cycle times, reducing overall production time.

- Uniformity: The induction heating ensures even heat distribution throughout the material, leading to consistent sintering results.

- Energy Savings: Induction heating is more energy-efficient as it minimizes heat loss, making it a cost-effective choice for manufacturers.

- High Quality: Sintered products exhibit superior mechanical properties due to the controlled heating environment and reduced thermal gradients during the process.

These advantages make the induction silicon carbide sintering furnace an excellent choice for businesses aiming to enhance their production efficiency and product quality.

Q4: Can the induction silicon carbide sintering furnace be used for other materials?

A4: Yes, while the induction silicon carbide sintering furnace is specifically designed for silicon carbide, it can also accommodate other materials that can be sintered effectively via induction heating. This includes various types of ceramics and composites that benefit from high-temperature processing. However, it is essential to ensure that the materials used are compatible with the induction heating process and the furnace design. If you are considering multiple materials for sintering, it’s best to consult with our technical team to assess suitability and optimize your sintering parameters.

Please feel free to consult for any additional questions or specifics related to your requirements for OUR Induction Silicon Carbide Sintering Furnace

!and Nanyang sinowin industry co.ltd are not only a lab and industrial furnace supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Technical Parameters of Induction Silicon Carbide Sintering Furnace:

| Working Size-DX(mm) | 400X400X1200 | 500X500X1600 | 600X600X1600 | 700X700X4000 |

| Utmost temperature (℃) | 2450 | 2450 | 2450 | 2450 |

| Working Temperature(℃) | 2400 | 2400 | 2400 | 2400 |

| Temperature uniformity(℃) | ±10 | ±10 | ±10 | ±10 |

| Working Voltage(V) | 3 phase,380 | |||

| Rated Power(KW) | 160 | 200 | 250 | 400 |

| Ultimate Vacuum(pa) | 0.1 | 0.1 | 0.1 | 0.1 |

| The above technical parameters of the silicon carbide sintering furnace can be adjusted according to the process parameters, not as a basis for acceptance, and shall be implemented according to the specific technical plan and agreement shall be implemented | ||||

Silicon carbide performance index::

| Index name | Atmospheric pressure sintered silicon carbide | Reaction sintered silicon carbide | Plus carbon silicon carbide |

| Purity (%) Silicon carbide content | > 97 | >90 | carbon content30% |

| Density (g/cm) ) | 3.06-3.15 | >3.05 | >2.65 |

| Granularity (um) | 0.5-0.7 | 8-20 | 20-40 |

| Hardness ( | ≥90 | ≥90 | ≥85 |

| Flexural strength MPa) | 400-580 | 350-450 | 200 |

| Compressive strength(MPa) | 3900 | >2500 | 1800 |

| Elastic modulus(GPa) | 380-410 | 420 | |

| Elastic modulus(GPa) | 380-410 | 420 | |

| Thermal conductivity | 102.6 | 35-110 | 125 |

| Thermal expansion coefficient (1/℃) | 4.02×10 | 4.3×10 | 3×10 |

| Poisson’s ratio | 0.14 | 0.15 |