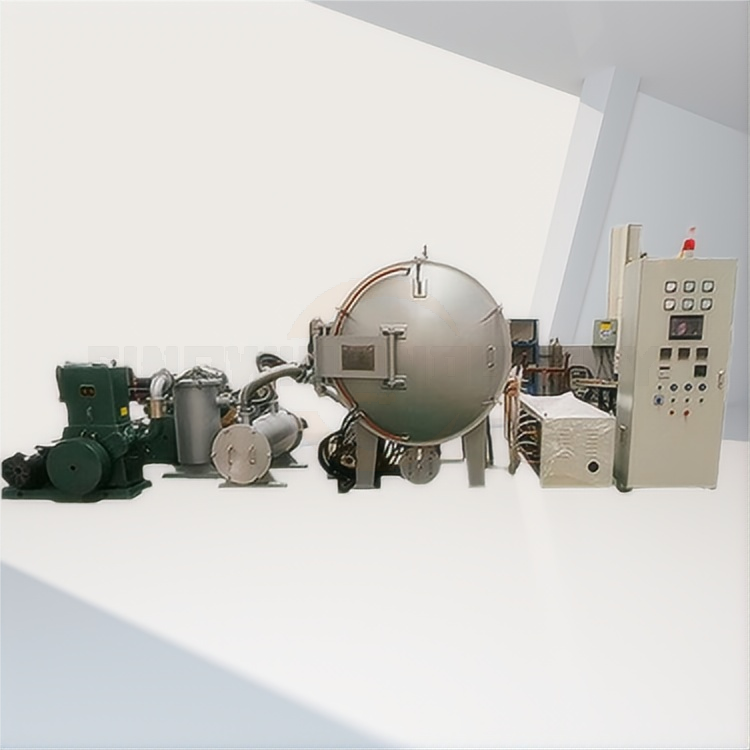

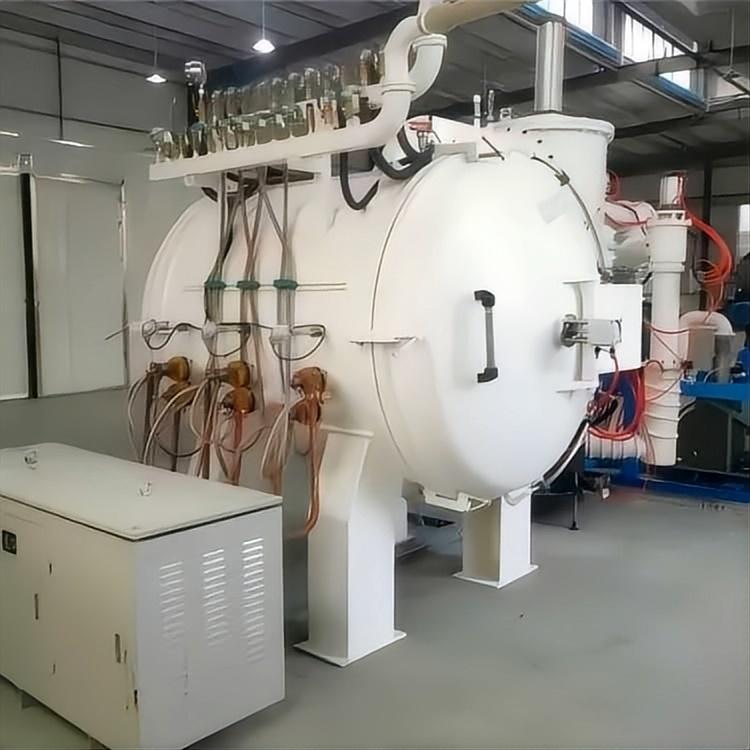

Product Description:

The Integrated Debinding and Sintering Furnace is specifically used for the debinding and sintering of injection-molded products made from a variety of materials, including iron-based alloys, stainless steel, titanium alloys, alloy steel, and high-speed steel. This advanced furnace seamlessly combines debinding and sintering processes, ensuring optimal results for manufacturers in the metalworking industry.

Key Features:

- Uniform Temperature Distribution: The furnace is equipped with a specially designed furnace lining structure and an innovative heater layout, ensuring excellent temperature uniformity throughout the chamber for consistent results.

- Effective Debinding System: Featuring a uniquely constructed debinding chamber with superior sealing effectiveness, our furnace guarantees complete debinding without contaminating the internal components.

- Versatile Operating Modes: This equipment boasts a range of functionalities, including flexible vacuum extraction, micro-positive pressure sintering, differential pressure sintering, negative pressure debinding, and micro-positive pressure debinding, catering to various process requirements.

- Superior Insulation Materials: Utilizing carbon fiber insulation structure and materials, the furnace exhibits excellent thermal insulation performance and minimal heat storage, promoting energy efficiency.

- User-Friendly Interface: Our furnace is designed with a touch screen operation and PLC centralized control, ensuring easy operation and high reliability for users.

- High Safety Standards: Equipped with over-temperature and over-pressure alarms, mechanical automatic pressure protection, and interlock mechanisms, this furnace guarantees high safety levels during operation.

- Remote Capabilities: The furnace supports remote operation, remote fault diagnosis, and remote software upgrades, making it a cutting-edge solution for today’s advanced manufacturing environments.

Specifications:

- Furnace Door: Manual locking / Automatic lock ring locking

- Furnace Shell: Full carbon steel / Inner layer stainless steel / Full stainless steel

- Furnace Lining: Soft carbon felt + Rigid composite felt / Full rigid composite felt

- Heating Element Material: Isostatic graphite / Press-molded high-grade graphite.

Parameter of the Integrated Debinding and Sintering Furnace:

| Specification of Debinding and Sintering Furnace | ||||

| Work size

W×H×L(mm) |

300×300×600 | 400×400×800 | 400×400×1500 | 500×500×2000 |

| Loading (kg) | 150 | 250 | 500 | 1000 |

| Work Temperature(℃) | 1550 | 1550 | 1550 | 1550 |

| Temperature uniformity(℃) | ±3 | ±3 | ±5 | ±5 |

| Heating Power(kw) | 75 | 90 | 145 | 240 |

| Ultimate vacuum(pa) | 1 | 1 | 1 | 1 |

| rate of pressure rise(pa/h) | 0.67 | 0.67 | 0.67 | 0.67 |

| Degreasing Atmosphere | Ar/N2 | Ar/N2 | Ar/N2 | Ar/N2 |

Q&As for vacuum sintering debinding furnace:

Q1: What types of materials can this vacuum sintering debinding furnace process?

A1: Our vacuum sintering debinding furnace is specifically designed to handle a wide range of materials including iron-based alloys, stainless steel, titanium alloys, alloy steels, and high-speed steels. This versatility makes it an indispensable tool for manufacturers focusing on injection-molded products in various industries.

Q2: How does the uniformity of temperature in the furnace affect the sintering process?

A2: The special furnace structure and heater arrangement of our debinding furnace ensure excellent temperature uniformity throughout the chamber. This uniformity is crucial as it not only guarantees consistent material properties in the final product but also improves overall processing efficiency, ensuring that each piece achieves optimal debinding and sintering results.

Q3: What safety features does the debinding furnace have?

A3: Your safety is our priority! Our debinding furnace is equipped with several safety features, including over-temperature and over-pressure alarms, mechanical automatic pressure protection, and interlocking actions to prevent any unsafe operations. These features work together to ensure reliable and safe furnace operations in your facility.

Q4: Can the device be operated remotely, and what advantages does that provide?

A4: Yes, our vacuum sintering debinding furnace supports remote operation, fault diagnosis, and software upgrades. This capability allows for enhanced operational efficiency as you can monitor and control the furnace from a distance, reducing downtime and improving response times in case of issues. This feature is ideal for modern manufacturing environments looking to optimize their processes.

Q5: How user-friendly is the operation of the furnace?

A5: The debinding furnace comes with an intuitive touch screen interface and centralized PLC control, making it extremely user-friendly. This design ensures that operators can easily navigate through the settings, enhancing the overall user experience. Its simplicity combined with its reliability makes it an excellent investment for both new and experienced operators.

Q6: What maintenance is required for the furnace?

A6: Proper maintenance is essential for the longevity of our vacuum sintering debinding furnace. We recommend regular checks of the heating elements, ensuring seals are intact, and monitoring safety systems to ensure they function properly. Routine maintenance not only prolongs the life of the furnace but also ensures continued high performance and safety.

The Integrated Debinding and Sintering Furnace is the ideal solution for manufacturers with reliable and efficient debinding and sintering processes.

Whether you are in research, analysis, or manufacturing, the Debinding and Sintering Furnace supplied from SINOWIN INDUSTRY is one guaranteed option for your heating treatment industry.

Donot hesitate to Contact us at once for quotation of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Parameter of the Integrated Debinding and Sintering Furnace:

| Specification of Debinding and Sintering Furnace | ||||

| Work size

W×H×L(mm) |

300×300×600 | 400×400×800 | 400×400×1500 | 500×500×2000 |

| Loading (kg) | 150 | 250 | 500 | 1000 |

| Work Temperature(℃) | 1550 | 1550 | 1550 | 1550 |

| Temperature uniformity(℃) | ±3 | ±3 | ±5 | ±5 |

| Heating Power(kw) | 75 | 90 | 145 | 240 |

| Ultimate vacuum(pa) | 1 | 1 | 1 | 1 |

| rate of pressure rise(pa/h) | 0.67 | 0.67 | 0.67 | 0.67 |

| Degreasing Atmosphere | Ar/N2 | Ar/N2 | Ar/N2 | Ar/N2 |