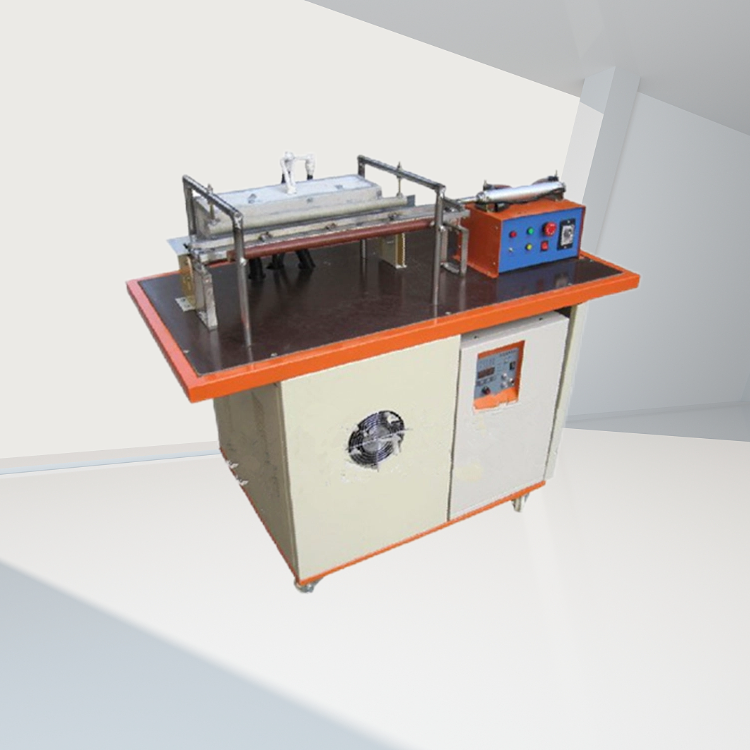

Product Description:

The Intermediate Frequency Induction Forging Furnace designed and produced by sinowin industry is for continuous heating of various materials including Φ12 and above steel, stainless steel, copper, aluminum, and other shapes of raw materials. This furnace is specifically designed for overall continuous heating, making it an ideal solution for achieving superior forging quality.

Key Applications:

The Intermediate Frequency Induction Heating Furnace is primarily utilized for heating round bars, square bars, and other irregularly shaped billets. Its outstanding performance ensures that your materials reach the desired temperature efficiently, enhancing productivity and reducing material waste.

Main Features:

- Versatile Material Heating: Effectively heats copper bars, iron bars, and aluminum profiles.

- Compact Design: With an ultra-small footprint of just 0.6 square meters, this movable furnace easily integrates with any forging or rolling equipment.

- Ease of Use: Installation, debugging, and operation are incredibly convenient, making it easy to learn and implement.

- Induction Heating Technology: Rapidly heats billets to the required temperature, significantly reducing metal oxidation, ultimately saving material and improving forging quality.

- Enhanced Heating Capacity: Specifically designed for Φ15 and above bars, offering more thorough, uniform, and rapid heating.

- Continuous Operation: Capable of working 24 hours without interruption to maximize output.

- Automated Feeding System: Streamlines the heating process for increased efficiency.

- Energy Efficient and Environmentally Friendly: Reduces costs and labor expenditures while promoting sustainable operation.

- Customizable Furnace Body: Easily replaceable furnace body to accommodate different heating needs, including overall and end heating.

- Advanced Power Supply: Utilizes an ultra-compact intermediate frequency induction heating power source, distinctly different from traditional intermediate frequency systems, comprising the power supply, compensation capacitor box, worktable, induction coil, and feeding device. Optional accessories may include infrared thermometers, temperature controllers, and feeding or coiling mechanisms adapted to specific applications.

Intermediate Frequency Heating Furnace Characteristics:

lBroad Frequency Range Operating between 1KHz – 20KHz, allowing selection of appropriate frequencies based on the diameter of the workpiece.

lEffective Heating Features induction coil lengths of 500mm to 1 meter, ensuring multiple billets are heated simultaneously for optimal thermal effectiveness.

lContinuous Heating Mode Addresses the stability of power throughout the heating cycle, maintaining the actual heating power above 85% of the rated value. This approach efficiently manages the significant load changes when raising a single billet from room temperature to 1100°C.

lHigh Capacity for Non-ferrous Metals When heating materials like copper and aluminum, the reasonable design of the induction coil and capacitors can achieve over 85% of actual power, with copper heating capabilities reaching 3.5KG/KW·hour.

lSpace-Saving and Economical Compared to silicon-controlled intermediate frequency power supplies, this model is not only more compact and easier to maintain but also saves 15-20% on energy consumption.

Elevate your forging process with the Intermediate Frequency Induction Forging Furnace – where efficiency, precision, and reliability meet. Optimize your operations today!

Main parameter of the Intermediate Frequency Induction Forging Furnace

(1) SWF- -35 / 45 / 70 / 90 / 11 / 160 medium frequency power supply

(2) Compensation capacitor and forging furnace workbench

(3) Induction ring, guide rail and outer cover

(4) Pneumatic feeding mechanism

- Input power: 35KW / 45KW / 70KW / 90KW / 110KW / 160 kW

- Output oscillation frequency: 1-20 KHZ

4, Input voltage: three-phase 380V 50 or 60 HZ

- Load persistence rate: 100%

- Cooling water requirements: 0.2MPa, 20L / min

- Heating capacity (KG / min)

(1) Steel to 1100℃:2.5KG/3.3KG/4.16KG

(2) Copper to 900℃: 3.5KG/4.6KG/5.8KG

8, table size: 1.4 meters long 0.7 meters wide 0.89 meters high

- Weight of forging furnace: 140 / 185 KG / 210 KG / 223 KG

10, used for continuous heating of steel, copper, aluminum and other rods or pipe material

Specification and heating capacity of the Intermediate Frequency Induction Forging Furnace:

| Main specifications | Input power | Heating capacity of commonly used materials | |

| Heat the steel feed to 1100℃ | Heat the brass material to 700℃ | ||

| SWF-35 Forge furnace | 35kw | 1.25 KG / min | 1.75 KG / min |

| SWF-45 Forge furnace | 45kw | 1.67 KG / min | 2.33 KG / min |

| SWF-70 Forge furnace | 70kw | 2.5 KG / min | 3.5 KG / min |

| SWF-90 Forge furnace | 90kw | 3.33 KG / min | 4.67 KG / min |

| SWF-110 forging furnace | 110kw | 4.17 KG / min | 5.83 KG / min |

| SWF-160 forging furnace | 160kw | 5.83 KG / min | 8 KG / cent |

Main parameters of power supply for medium-frequency forging furnace:

| model | SWF—35 | SWF—45 | SWF—70 | SWF—90 | SWF—110 | SWF—160 |

| Input power | 35KVA | 45KVA | 70KVA | 90KVA | 110KVA | 160KVA |

| output | 10~70A | 15~95A | 20~130A | 25~170A | 30~200A | 30~250A |

| output voltage | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V |

| Enter the power supply | Three-phase 380V ± 20% 50 or 60 HZ | |||||

| Output oscillation frequency | 1 KHZ ~ 20 KHZ according to the customer work-piece heating requirements | |||||

| cyclic duration factor | 100% 24 hours, continuous work | |||||

| Power weight |

40KG |

50KG | 60KG | 80KG | 100KG | 122KG |

| Power supply volume (width, height and length) CM |

27×45×52 |

35×55×65 | 50×88×75 | 50×88×75 | ||

| Medium-frequency complete set of cooling water requirements |

≥0.3Mpa ≥10L/Min |

≥0.3Mpa ≥20L/Min | ≥0.3Mpa ≥25L/Min | |||

| Requirements for cooling water of medium-frequency power supply |

≥0.2Mpa ≥4L/Min |

≥0.2Mpa ≥6L/Min | ≥0.2Mpa ≥6L/Min | |||

Invest in our Intermediate Frequency Induction Forging Furnace for your metal melting needs and experience unmatched efficiency, precision, and reliability. Sinowin industry supply the indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with long-term trusted and reliable service. Please feel free to consult for any additional questions or specifics.

Specification and heating capacity of the Intermediate Frequency Induction Forging Furnace:

| Main specifications | Input power | Heating capacity of commonly used materials | |

| Heat the steel feed to 1100℃ | Heat the brass material to 700℃ | ||

| SWF-35 Forge furnace | 35kw | 1.25 KG / min | 1.75 KG / min |

| SWF-45 Forge furnace | 45kw | 1.67 KG / min | 2.33 KG / min |

| SWF-70 Forge furnace | 70kw | 2.5 KG / min | 3.5 KG / min |

| SWF-90 Forge furnace | 90kw | 3.33 KG / min | 4.67 KG / min |

| SWF-110 forging furnace | 110kw | 4.17 KG / min | 5.83 KG / min |

| SWF-160 forging furnace | 160kw | 5.83 KG / min | 8 KG / cent |

Main parameters of power supply for medium-frequency forging furnace:

| model | SWF—35 | SWF—45 | SWF—70 | SWF—90 | SWF—110 | SWF—160 |

| Input power | 35KVA | 45KVA | 70KVA | 90KVA | 110KVA | 160KVA |

| output | 10~70A | 15~95A | 20~130A | 25~170A | 30~200A | 30~250A |

| output voltage | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V |

| Enter the power supply | Three-phase 380V ± 20% 50 or 60 HZ | |||||

| Output oscillation frequency | 1 KHZ ~ 20 KHZ according to the customer work-piece heating requirements | |||||

| cyclic duration factor | 100% 24 hours, continuous work | |||||

| Power weight |

40KG |

50KG | 60KG | 80KG | 100KG | 122KG |

| Power supply volume (width, height and length) CM |

27×45×52 |

35×55×65 | 50×88×75 | 50×88×75 | ||

| Medium-frequency complete set of cooling water requirements |

≥0.3Mpa ≥10L/Min |

≥0.3Mpa ≥20L/Min | ≥0.3Mpa ≥25L/Min | |||

| Requirements for cooling water of medium-frequency power supply |

≥0.2Mpa ≥4L/Min |

≥0.2Mpa ≥6L/Min | ≥0.2Mpa ≥6L/Min | |||