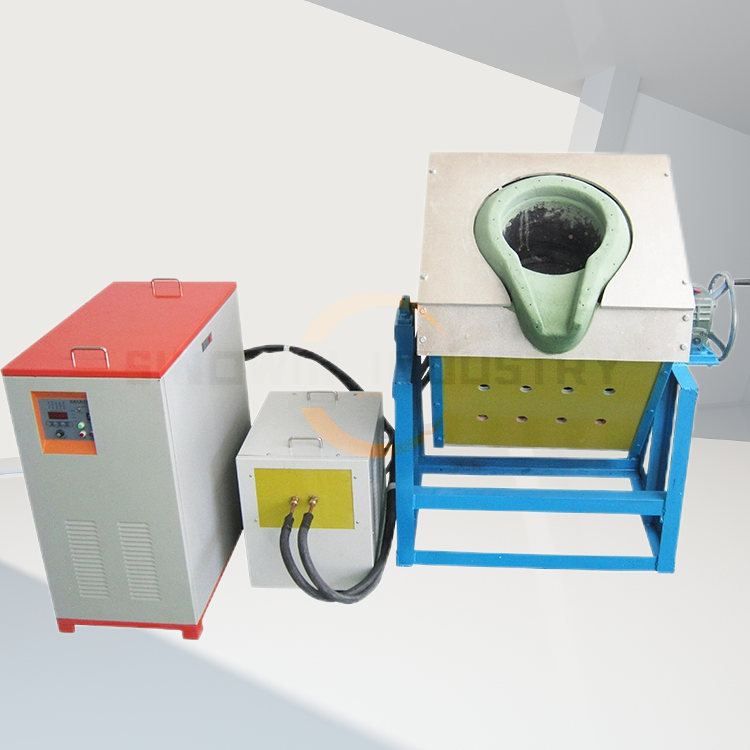

Product Name: Medium Frequency Gold Melting Furnace

Product Description:

The Medium Frequency Gold Melting Furnace produced by sinowin industry with technical parameters ranging from 15 to -70 kW and an oscillation frequency of 2-20 kHz, is designed to handle a melting capacity of 2kg to 50kg of different precious metals, reaching furnace temperatures of up to 1700 degrees Celsius in a swift 5 to 30 minutes.

Our company specializes in producing high-frequency melting furnaces with capacities of 2kg and 4kg, alongside medium frequency furnaces for 10kg, 20kg, 30kg, 50kg, 100kg, 120kg, and 150kg. Utilizing a crucible container, our melting technology ensures metals are rapidly heated before the melting process initiates, allowing for efficient smelting, refining, purifying, and casting procedures.Sinowin industry supply the indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with long-term trusted and reliable service.

Key Features of the Medium Frequency Gold Melting Furnace:

- Convenient installation and operation: User-friendly design allows for immediate adaptability.

- High efficiency with low power consumption: Compact size and lightweight nature make the furnace portable, occupying less than 1 square meter.

- 24/7 melting capability: Designed for continuous operation without compromise.

- Energy-saving and environmentally friendly: Produces no noise or harmful emissions, and significantly reduces electricity usage, outperforming conventional coal, gas, and oil-based furnaces.

- Quick crucible replacement: Simplifies the workflow and enhances operational speed.

- Safe operation: Mitigates the risks associated with high-pressure systems while providing a low surrounding temperature and minimal smoke output, ensuring a clean work environment.

Comprehensive Specifications Include:

- Types of power supply High-frequency and medium-frequency options tailored to various needs.

- Furnace designs Choose from integrated, split, tilting, and fixed styles with coil variations, all designed with specific advantages for diverse applications.

- Basic components Includes a small medium frequency induction heating power supply and either manual or automatic tilting furnace body options, accompanied by compensation capacitor boxes.

What is the Applications of the Medium Frequency Gold Melting Furnace?

The Medium Frequency Gold Melting Furnace designed and manufactured by sinowin industry is ideally suited for melting and heating metals, including but not limited to steel, stainless steel, copper, aluminum, gold, and silver, with melting quantities ranging from 3kg to 300kg. The electromagnetic stirring capabilities enhance the uniformity of temperature and structure during melting, effectively reducing impurities.

Our furnace excels in various environments, making it the preferred choice for modern manufacturers, schools, and research institutions seeking reliable and efficient melting equipment.

With our metal melting technology of our Medium Frequency Gold Melting Furnace where innovation meets quality to enhance your business.

lease feel free to consult for any additional questions or specifics related to your requirements for the Medium Frequency Gold Melting Furnace!and Sinowin industry not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Main parameters of power supply for medium-frequency smelting furnace:

| Model | SWI—15 | SWI—25 | SWI—35 | SWI—45 | SWI—70 | SWI—90 | SWI—110 | SWI—160 |

| Input power | 15KVA | 25KVA | 35KVA | 45KVA | 70KVA | 90KVA | 110KVA | 160KVA |

| Output current | 3~22A | 5~45A | 10~70A | 15~95A | 20~130A | 25~170A | 30~200A | 30~250A |

| Output voltage | 70~520V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V |

| Power supply | Three-phase 380V ± 20% 50 or 60 HZ | |||||||

| Output oscillation frequency | 1 KHZ ~ 20 KHZ according to the customer work-piece heating requirements | |||||||

| Cyclic duration factor | 100% 24 hours, continuous work | |||||||

| Power weight | 28KG | 30KG | 40KG | 50KG | 60KG | 80KG | 100KG | 122KG |

| Power supply volume (width, height and length) CM | 27×45×46 | 27×45×52 | 35×55×65 | 50×88×75 | 50×88×75 | |||

| Complete set of cooling water requirements of the Medium-frequency induction furnace | ≥0.2Mpa ≥6L/Min | ≥0.3Mpa ≥10L/Min | ≥0.3Mpa ≥20L/Min | ≥0.3Mpa ≥25L/Min | ||||

| Requirements for cooling water of medium-frequency power supply | ≥0.2Mpa ≥3L/Min | ≥0.2Mpa ≥4L/Min | ≥0.2Mpa ≥6L/Min | ≥0.2Mpa ≥6L/Min | ||||

| Power waterway | One Water Inlet; One Water Outlet | One Water Inlet; Three Water Outlet | ||||||

Specification and heating capacity of the Intermediate Frequency Induction Smelting Furnace:

| Specifications | Steel, iron | Gold, silver, copper, and tin | Aluminum, aluminum alloy | Input voltage | Input power |

| SWI-15 Smelting Furnace | 2kg | 10kg | 3kg | 380v | 15kw |

| SWI-25 Smelting Furnace | 4kg | 20kg | 6kg | 380v | 25kw |

| SWI-35 Smelting Furnace | 8kg | 40kg | 10kg | 380v | 35kw |

| SWI-45 Smelting Furnace | 12kg | 50kg | 20kg | 380v | 45kw |

| SWI-70 Smelting Furnace | 25kg | 100kg | 30kg | 380v | 70kw |

| SWI-90 Smelting Furnace | 40kg | 120kg | 50kg | 380v | 90kw |

| SWI-110 Smelting Furnace | 50kg | 150kg | 80kg | 380v | 110kw |

| SWI-160 Smelting Furnace | 70kg | 250kg | 200kg | 380v | 160kw |

| Note | The heating capacity of each type of smelting furnace is listed in the table below. When the furnace is cold, the smelting time for each furnace is 50 to 60 minutes. When the furnace is hot, the smelting time for each furnace is 20 to 30 minutes. | ||||