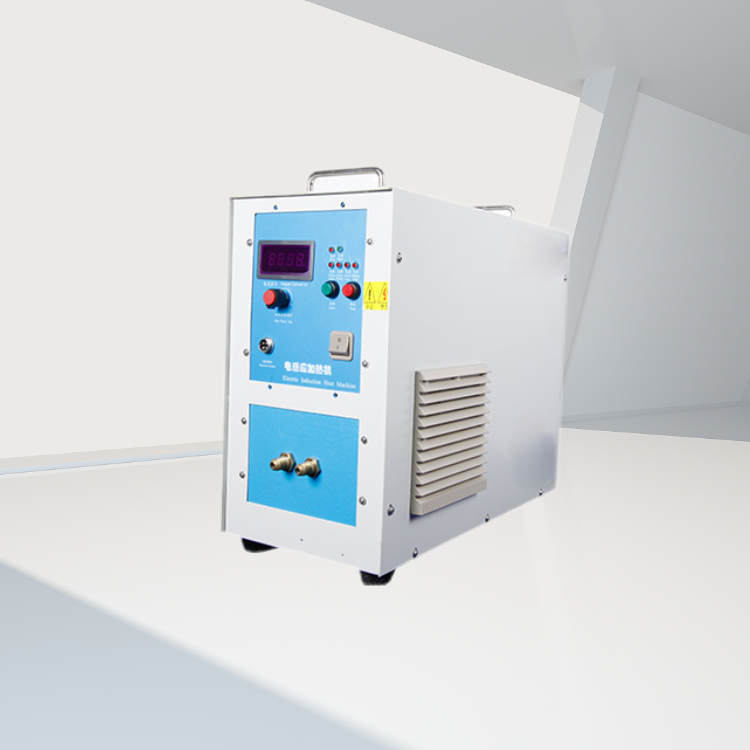

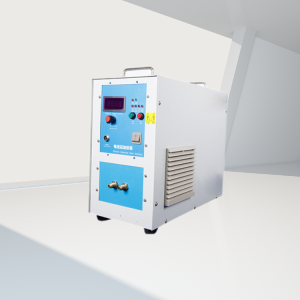

Product Title: Medium Frequency Induction Heating Power Supply (SWI Series)

Product Description:

The SWI Series Medium Frequency Induction Heating Power Supply designed and produced by sinowin industry – a cutting-edge thermal solution designed to enhance your heating applications with unparalleled efficiency and reliability.

The SWI series medium frequency induction heating power supply produced by sinowin industry stands out due to its utilization of all-solid-state IGBT technology, providing precise frequency control and power adjustment. This innovative design incorporates comprehensive protection features such as overcurrent protection, low-water protection, overheating protection, overvoltage protection, short-circuit protection, and phase loss protection, ensuring the utmost reliability and facilitating maintenance.

With an intuitive display functionality showcasing frequency, current, voltage, and power status, operators can easily monitor the device’s operating conditions. This enhanced visibility assists in optimizing the design of the induction coil and capacitor adjustments, promoting a more effective heating process.

Notably compact and lightweight, the SWI series medium frequency induction heating power supply saves clients up to 10 times the production space compared to conventional thyristor-based systems. Capable of operating continuously at full load for 24 hours, this power supply delivers high efficiency and energy savings across all power ranges, boasting excellent power factor and source efficiency.

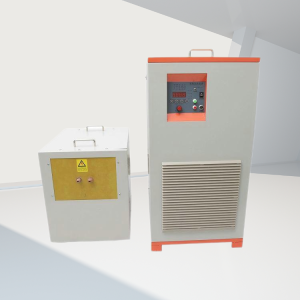

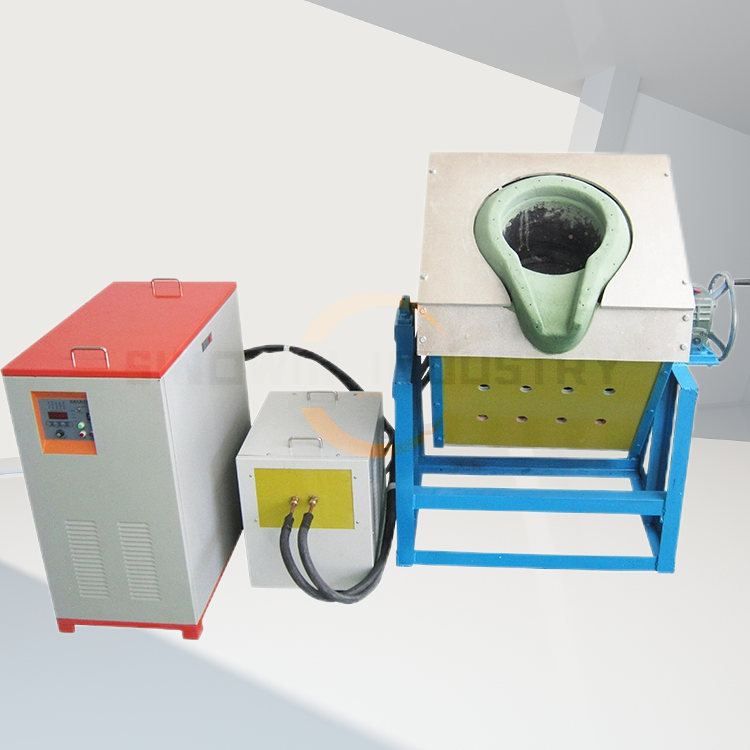

The SWI series induction heating furnace is constructed with a parallel resonant circuit that allows for versatile applications, including direct output configurations. Its fundamental structure integrates a medium frequency power supply, capacitor, and induction coil, making it perfectly suited for common applications like medium frequency forging furnaces and melting furnaces. This simplicity reduces loss, elevates operational efficiency, and minimizes manufacturing costs.

In scenarios requiring long induction coils, typically constructed from 3 to 10 meters of copper tubing, the SWI medium frequency power supply delivers a compelling voltage output of 550V directly to the induction coil. Note that since this design does not isolate from the main power supply, it is imperative that the induction coil is well insulated and not exposed to external elements.

Generally regarded as a standard product, the medium frequency induction heating power supply produced by sinowin industry automatically follows a frequency range of 1–20 kHz. Customized designs for the capacitor box and induction coil can be engineered based on the specific heating workpieces and requirements, achieving optimal heating effects and efficiency.

Main Features of the Medium Frequency Induction Heating Power Supply

- Advanced Solid-State Technology: The SWI medium frequency induction power supply utilizes all-solid-state IGBT frequency conversion and power regulation, ensuring enhanced reliability and reduced maintenance requirements with built-in protective functions including overcurrent, under-voltage, overheating, over-voltage, short-circuit, and phase loss protection.

- Intuitive Display Features: Our induction power supply is equipped with comprehensive display functionalities such as frequency, current, voltage, and power indicators, providing real-time insights into operational status, which aids in the precise design of induction coils and capacitor adjustments.

- Compact and Lightweight Design: Compared to conventional thyristor-based induction power supplies, the SWI series is significantly smaller and lighter, saving up to 10 times the production space, making it an ideal choice for facilities with limited space.

- Continuous High-Load Operation: Designed to operate at a full load, the SWI medium frequency induction power supply offers 24-hour continuous working capability, ensuring high efficiency and energy savings with a superior power factor and efficiency across the entire power range.

- Customizable to Your Needs: Our standard frequency range of 1-20 kHz is automatically adjustable to match your heating demands. We also provide tailored design options for capacitor boxes and induction coils, optimizing heating performance and efficiency for applications such as medium frequency forging and melting furnaces.

Main parameters of power supply for medium-frequency smelting furnace

| Model | SWI—15 | SWI—25 | SWI—35 | SWI—45 | SWI—70 | SWI—90 | SWI—110 | SWI—160 |

| Input power | 15KVA | 25KVA | 35KVA | 45KVA | 70KVA | 90KVA | 110KVA | 160KVA |

| Output current | 3~22A | 5~45A | 10~70A | 15~95A | 20~130A | 25~170A | 30~200A | 30~250A |

| Output voltage | 70~520V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V |

| Power supply | Three-phase 380V ± 20% 50 or 60 HZ | |||||||

| Output oscillation frequency | 1 KHZ ~ 20 KHZ according to the customer work-piece heating requirements | |||||||

| Cyclic duration factor | 100% 24 hours, continuous work | |||||||

| Power weight | 28KG | 30KG | 40KG | 50KG | 60KG | 80KG | 100KG | 122KG |

| Power supply volume (width, height and length) CM | 27×45×46 | 27×45×52 | 35×55×65 | 50×88×75 | 50×88×75 | |||

| Complete set of cooling water requirements of the Medium-frequency induction furnace | ≥0.2Mpa ≥6L/Min | ≥0.3Mpa ≥10L/Min | ≥0.3Mpa ≥20L/Min | ≥0.3Mpa ≥25L/Min | ||||

| Requirements for cooling water of medium-frequency power supply | ≥0.2Mpa ≥3L/Min | ≥0.2Mpa ≥4L/Min | ≥0.2Mpa ≥6L/Min | ≥0.2Mpa ≥6L/Min | ||||

| Power waterway | One Water Inlet; One Water Outlet | One Water Inlet; Three Water Outlet | ||||||

Purchase our SWI Series Medium Frequency Induction Heating Power Supply to elevate your heating solutions with superior technology and exceptional performance,sinowin industry supply the top quality&service to support all clients from the world.

Please feel free to consult for any additional questions or specifics related to your requirements for our Medium Frequency Induction Heating Power Supply! Sinowin industry not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Main parameters of power supply for medium-frequency smelting furnace

| Model | SWI—15 | SWI—25 | SWI—35 | SWI—45 | SWI—70 | SWI—90 | SWI—110 | SWI—160 |

| Input power | 15KVA | 25KVA | 35KVA | 45KVA | 70KVA | 90KVA | 110KVA | 160KVA |

| Output current | 3~22A | 5~45A | 10~70A | 15~95A | 20~130A | 25~170A | 30~200A | 30~250A |

| Output voltage | 70~520V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V | 70~550V |

| Power supply | Three-phase 380V ± 20% 50 or 60 HZ | |||||||

| Output oscillation frequency | 1 KHZ ~ 20 KHZ according to the customer work-piece heating requirements | |||||||

| Cyclic duration factor | 100% 24 hours, continuous work | |||||||

| Power weight | 28KG | 30KG | 40KG | 50KG | 60KG | 80KG | 100KG | 122KG |

| Power supply volume (width, height and length) CM | 27×45×46 | 27×45×52 | 35×55×65 | 50×88×75 | 50×88×75 | |||

| Complete set of cooling water requirements of the Medium-frequency induction furnace | ≥0.2Mpa ≥6L/Min | ≥0.3Mpa ≥10L/Min | ≥0.3Mpa ≥20L/Min | ≥0.3Mpa ≥25L/Min | ||||

| Requirements for cooling water of medium-frequency power supply | ≥0.2Mpa ≥3L/Min | ≥0.2Mpa ≥4L/Min | ≥0.2Mpa ≥6L/Min | ≥0.2Mpa ≥6L/Min | ||||

| Power waterway | One Water Inlet; One Water Outlet | One Water Inlet; Three Water Outlet | ||||||