Product Description:

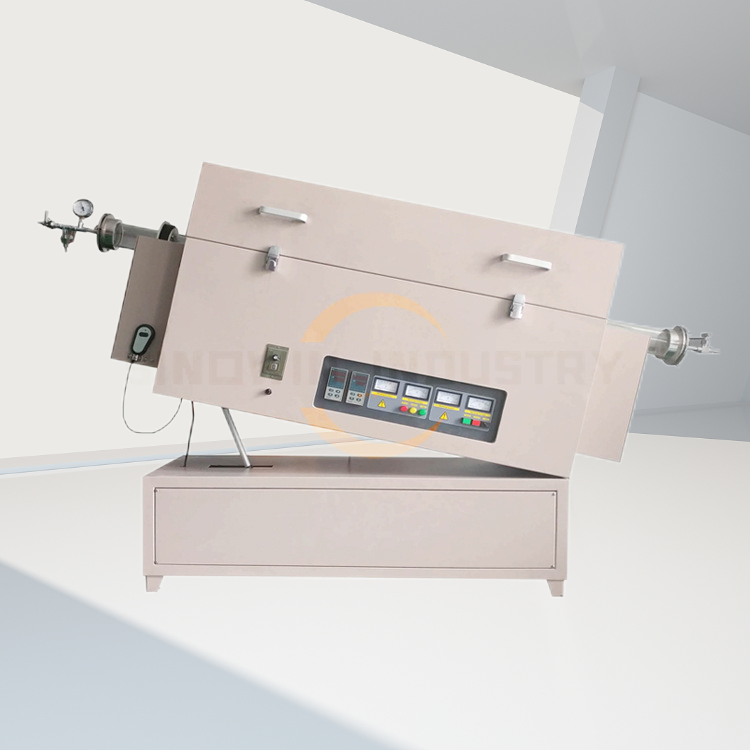

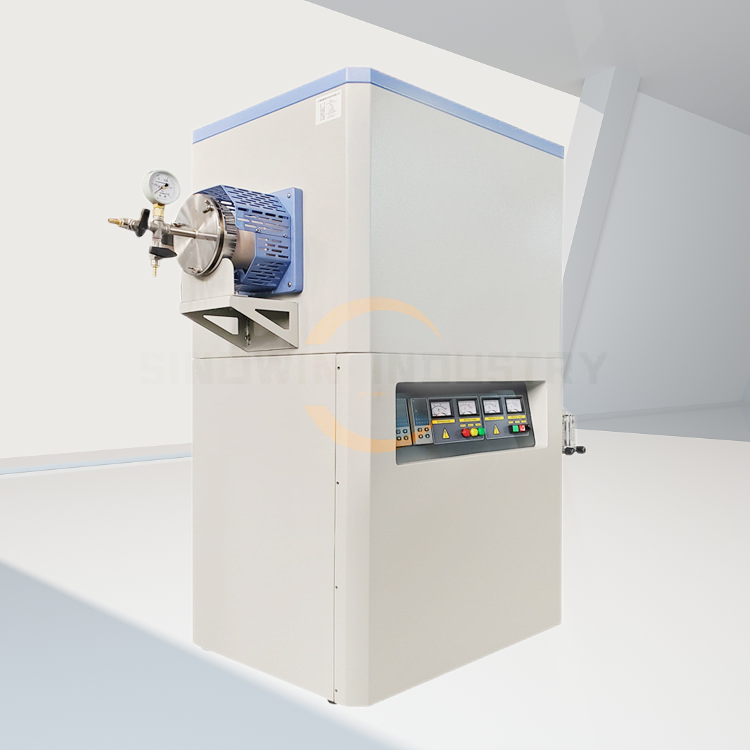

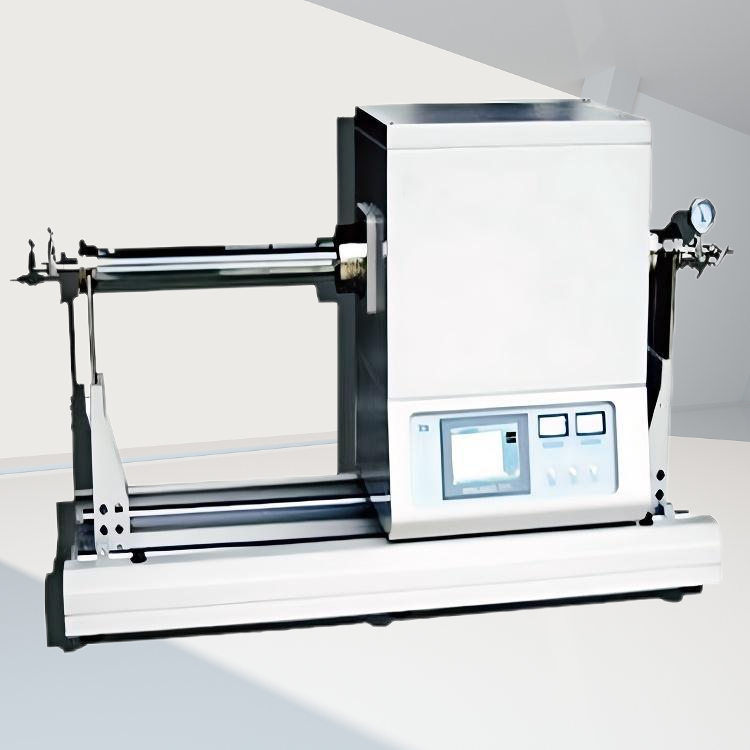

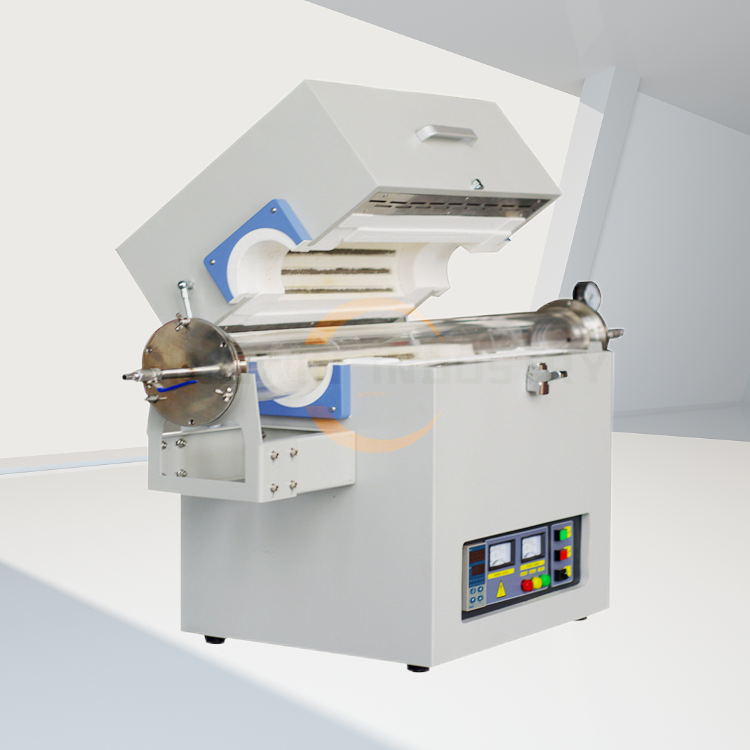

The Multi-Zone Tube Furnace designed and manufactured by Sinowin Industry is applied for advanced material processing. With a maximum operating temperature of 1600°C, this tube furnace meets the needs of various applications in educational institutions, research laboratories, and industrial settings.

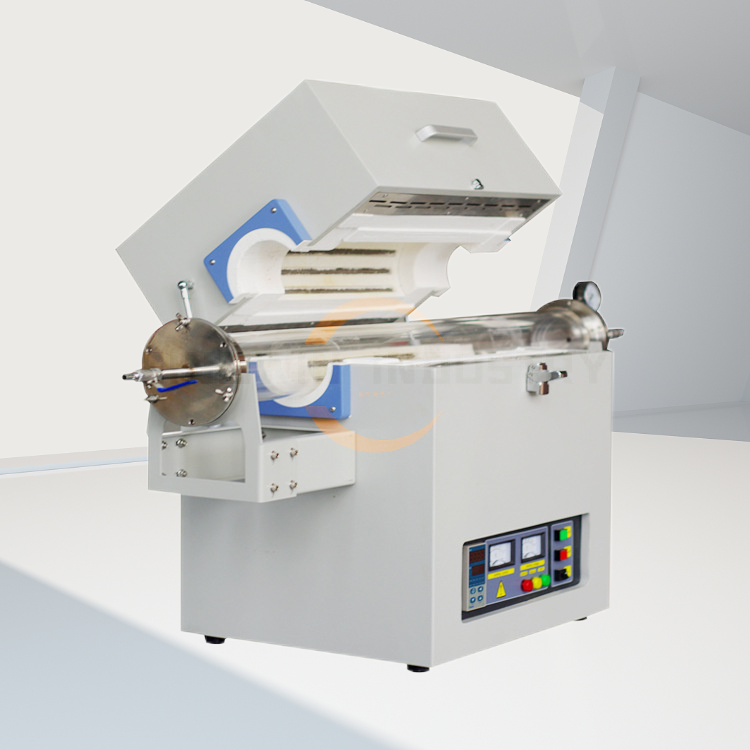

Constructed with high-purity quartz or high-purity alumina tubes, the Multi-Zone Tube Furnace operates seamlessly within a temperature range of 300°C to 1600°C. Customers can select the ideal specifications based on their unique requirements. The cutting-edge control system of this furnace is internationally recognized for its safety, reliability, user-friendly interface, high temperature control precision, superior insulation properties, and excellent temperature uniformity throughout the chamber. Additionally, it supports gas atmosphere operation and vacuum conditions, making it ideal for high-temperature Sintering experiments, material quality testing, and small-batch production processes.

This Multi-Zone Tube Furnace is equipped with 2 to 5 individual heating zones, allowing for independent temperature control in each zone. Users can choose from three specific temperature settings: 1200°C, 1400°C, and 1600°C.

Key Features of the Sinowin Multi-Zone Tube Furnace:

lOptions for Dual, Tree-Zone, or Pent-Zone configurations

lEach heating zone can be individually controlled

lPerfect for processes such as pre-sintering, Sintering, film coating, high-temperature pyrolysis, low-temperature deposition (CVD), carbon nanotube synthesis, and silicon nanowire fabrication in vacuum or protective gas atmospheres.

Advantages of Sinowin Multi-Zone Tube Furnace:

lHigh-Performance Heating Capability The Multi-Zone Tube Furnace boasts a maximum temperature of 1600°C, ideal for high-temperature Sintering of metal materials and various advanced material processes, ensuring versatility for laboratory and production applications.

lPrecise Temperature Control With 2 to 5 independently controlled heating zones, this furnace allows for precise temperature regulation across different thermal profiles, making it suitable for demanding processes such as CVD and high-temperature pyrolysis.

lSuperior Construction Materials Built with high-purity quartz or alumina tubes, the Multi-Zone Tube Furnace provides excellent thermal resistance and minimizes contamination, ensuring reliability and consistency in your experimental and production results.

lAdvanced Safety Features Designed with a state-of-the-art control system that prioritizes safety and ease of use, the furnace includes effective insulation and high uniformity in chamber temperature, optimizing performance and user experience during high-precision operations.

lComprehensive Support and Components Each Multi-Zone Tube Furnace package includes essential accessories such as four pipe plugs, a thermocouple, a furnace tube, a vacuum pump, a vacuum flange, and a pressure gauge, along with customer-focused after-sales support to ensure optimal functionality and satisfaction.

Standard Accessories Included:

l4 tube stoppers

l1 thermocouple

l1 furnace tube

l1 vacuum pump

l1 vacuum flange set

l1 vacuum pressure gauge

The Multi-Zone Tube Furnace is your indispensable tool for advanced material processing and experimentation with its excellent performance.

Parameter of Sinowin Multi-Zone Tube Furnace

Size of Sinowin Industry’s 1200℃ Multi-Zone Tube Furnace

| Chamber Size

(Dia*Heating Area) |

Power (KW) | Max.Temperature | Heating Area | Thermoelectric couple | Furnace tube | Heating Element |

| 40x220x220mm | 5 KW | 1200 | Double hot zone | K type | Quartz tube | Resistance wire |

| 60x220x220mm | 5 KW | |||||

| 80x220x220mm | 6 KW | |||||

| 100x300x300mm | 12 KW | |||||

| 120x300x300mm | 12 KW |

Size of Sinowin Industry’s 1400℃ Multi-Zone Tube Furnace

| Chamber Size

(Dia*Heating Area) |

Power (KW) | Max.Temperature | Heating Area | Thermoelectric couple | Furnace tube | Heating Element |

| 40x220x220mm | 5 KW | 1400℃ | Double hot zone | S Type | Alumina tube | Sic |

| 60x220x220mm | 5 KW | |||||

| 80x220x220mm | 6 KW | |||||

| 100x300x300mm | 12 KW | |||||

| 120x300x300mm | 12 KW |

Size of Sinowin Industry‘s 1600℃ Multi-Zone Tube Furnace

| Chamber Size

(Dia*Heating Area) |

Power (KW) | Max.Temperature | Heating Area | Thermoelectric couple | Furnace tube | Heating Element |

| 40x220x220mm | 6 KW | 1600℃ | Double hot zone | B Type | Alumina tube | MoSi2 |

| 60x220x220mm | 6 KW | |||||

| 80x220x220mm | 6 KW | |||||

| 100x300x300mm | 12 KW | |||||

| 120x300x300mm | 12 KW |

Experience unparalleled heating versatility and precision with Sinwon Industry’s Multi-Zone Tube Furnace—your solution for advanced material processing needs.

Whether you are in research, analysis, or manufacturing, the Multi-Zone Tube Furnace supplied from SINOWIN INDUSTRY is one guaranteed option for your heating treatment industry.

Donor hesitate to Contact us at once for any further information of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Parameter of Sinowin Multi-Zone Tube Furnace

Size of Sinowin Industry’s 1200℃ Multi-Zone Tube Furnace

| Chamber Size

(Dia*Heating Area) |

Power (KW) | Max.Temperature | Heating Area | Thermoelectric couple | Furnace tube | Heating Element |

| 40x220x220mm | 5 KW | 1200 | Double hot zone | K type | Quartz tube | Resistance wire |

| 60x220x220mm | 5 KW | |||||

| 80x220x220mm | 6 KW | |||||

| 100x300x300mm | 12 KW | |||||

| 120x300x300mm | 12 KW |

Size of Sinowin Industry’s 1400℃ Multi-Zone Tube Furnace

| Chamber Size

(Dia*Heating Area) |

Power (KW) | Max.Temperature | Heating Area | Thermoelectric couple | Furnace tube | Heating Element |

| 40x220x220mm | 5 KW | 1400℃ | Double hot zone | S Type | Alumina tube | Sic |

| 60x220x220mm | 5 KW | |||||

| 80x220x220mm | 6 KW | |||||

| 100x300x300mm | 12 KW | |||||

| 120x300x300mm | 12 KW |

Size of Sinowin Industry‘s 1600℃ Multi-Zone Tube Furnace

| Chamber Size

(Dia*Heating Area) |

Power (KW) | Max.Temperature | Heating Area | Thermoelectric couple | Furnace tube | Heating Element |

| 40x220x220mm | 6 KW | 1600℃ | Double hot zone | B Type | Alumina tube | MoSi2 |

| 60x220x220mm | 6 KW | |||||

| 80x220x220mm | 6 KW | |||||

| 100x300x300mm | 12 KW | |||||

| 120x300x300mm | 12 KW |