Product Description:

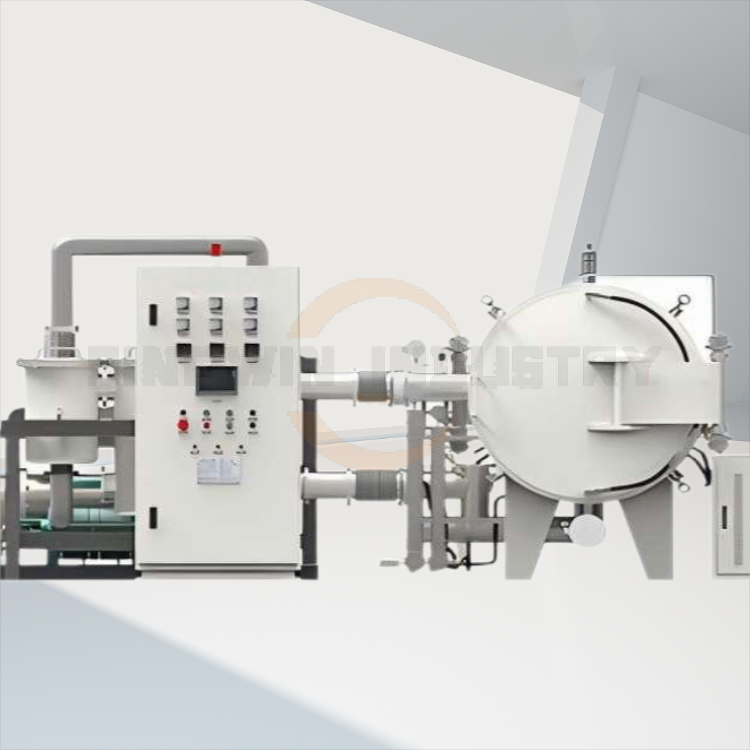

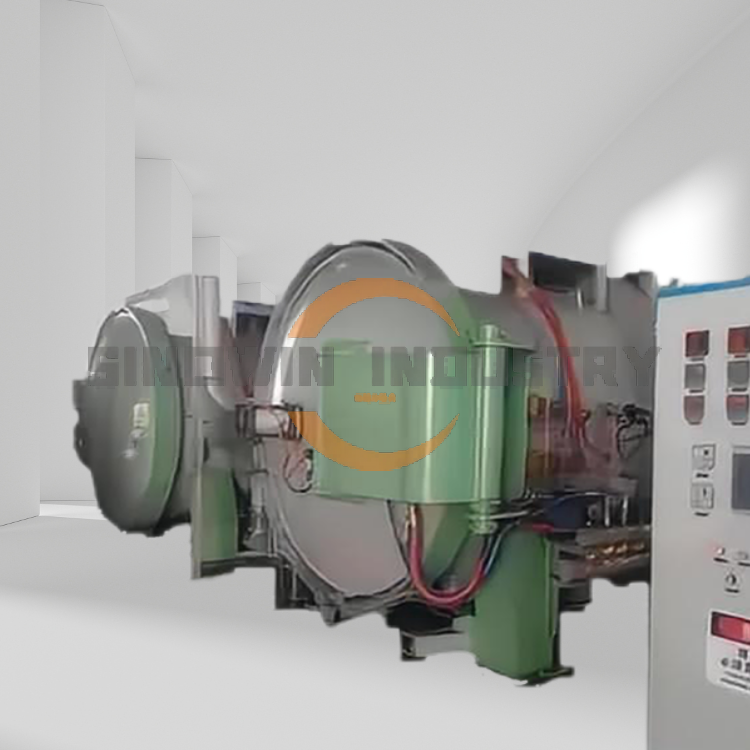

The PI (Polyimide) Film High-Temperature Graphitization Furnace, is an innovative heat treatment solution for advanced material processing. Available in both vertical and horizontal structures, this furnace features a top-opening lid for the upright design and front-and-rear opening doors for the horizontal version. With a double-layer water cooling structure and an inner chamber crafted from 304 stainless steel, it integrates cooling water in the interlayer to ensure optimal thermal management. The furnace allows for both vacuum operation and the introduction of protective gas, enhancing its utility across various applications.

Key Features:

- High-Temperature Capability: The PI Film High-Temperature Graphitization Furnace operates at a maximum temperature of 3000°C, with a typical working temperature of 2800°C, making it ideal for graphite purification tasks.

- Dual Structure Configuration: A standard configuration supports one power supply for two furnace bodies, while customization options are available for industries with special needs, such as graphite purification, allowing for a one-to-many configuration.

- Customizable Dimensions: The furnace typically features a uniform heating zone size of φ600MM×1600MM or φ500MM×1300MM. However, dimensions can be tailored to meet specific customer requirements.

- Superior Temperature Control: The furnace offers temperature uniformity of ≤±10°C and precision control of ±1°C, ensuring consistent and reliable operation.

- Working Atmosphere Options: It supports a vacuum replacement atmosphere with Ar2 or N2 protection (slightly positive pressure), providing the necessary conditions for various applications.

- Advanced Temperature Measurement: Equipped with an imported infrared optical temperature gauge, the measuring range spans from 1000°C to 3000°C with a precision of 0.3%.

- Automated Safety Features: The system includes automatic explosion-proof valves, as well as real-time monitoring of water pressure and flow, ensuring safety throughout the operation.

- Temperature Control Options: Users can choose between program-controlled or manual temperature settings, with a control precision of ±5°C.

- Enhanced Vacuum System: The vacuum acquisition system comprises a direct-coupled mechanical pump, along with gas-inflation electromagnetic vacuum valves, butterfly valves, a diaphragm valve, and necessary piping. This ensures efficient operation and reliability.

Technical Paramete of the PI Film Graphitization Furnace:

| Work Size (mm) | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Volume(L) | 9 | 28 | 125 | 196 | 282 | 452 |

| Heating Power | 100 KW | 160 KW | 200 KW | 250 KW | 300 KW | 350 KW |

| Frequency | 2000 Hz | 2000 Hz | 2000 Hz | 1500 Hz | 1500 Hz | 1500 Hz |

| Max. Work Temperature | 3000°C | |||||

| Ultra Vacuum | 1.2×10-3 mbar | |||||

| Optional High Vacuum | 5×10-5 mbar | |||||

| Max.temperature rise rate | 15°C/min (RT~1500°C), 10°C/min (1500°C~2500°C), 5°C/min (2500°C~3000°C) | |||||

| Vacuum Pressure Rise | 6.7×10-3 mbar/hr | |||||

| Atmosphere | High Vacuum(optional)/ Vacuum/ Inert Gas(Ar or N2)

Vacuum and high vacuum atmospheres are only allowed below 2200°C |

|||||

| Power | 3P, 380V, 50Hz/60Hz | |||||

| Pressure of the cooling water | 1.5~2.5 bar | |||||

| Temperature of the cooling water | ≤28 °C | |||||

Optional Features:

- High-Vacuum System: Tailored vacuum systems (including roots pump, diffusion pump, molecular pump, and slide valve pump) are available based on user requirements.

- Closed-Loop Cooling Water System

- Thyristor Power Supply / IGBT Power Supply

The PI (Polyimide) Film High-Temperature Graphitization Furnace is designed for professionals seeking high-performance and reliability in their material processing needs. Whether you are in research, analysis, or manufacturing, the PI (Polyimide) Film High-Temperature Graphitization Furnace supplied from SINOWIN INDUSTRY is one guaranteed option for your heating treatment industry.

Donot hesitate to Contact us at once for quotation of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Q&A for PI Film High-Temperature Graphitization Furnace

Q1: What is the purpose of the PI Film High-Temperature Graphitization Furnace?

A1: The PI Film High-Temperature Graphitization Furnace is designed to transform polyimide (PI) films into graphite through a high-temperature process. This conversion enhances the thermal, electrical, and mechanical properties of the material, making it suitable for various applications, particularly in electronics, aerospace, and advanced material development.

Q2: How does the high-temperature graphitization furnace work?

A2: The high-temperature graphitization furnace operates by heating the PI film to elevated temperatures in a controlled atmosphere. This process facilitates the thermal decomposition of the polymer, leading to carbonization and subsequent graphitization. The precise temperature control and environment within the furnace ensure optimal conversion of the PI film into graphite, preserving the material’s desired characteristics.

Q3: What are the benefits of using PI films for high-temperature graphitization?

A3: Utilizing PI films in high-temperature graphitization offers several advantages, including excellent thermal stability, superior electrical conductivity, and high mechanical strength post-processing. The resulting graphite possesses enhanced properties that make it ideal for applications in batteries, conductive polymers, and thermal management systems, providing a significant performance boost over conventional materials.

Q4: What key features should be considered when purchasing a graphitization furnace?

A4: When choosing a graphitization furnace, consider essential features such as maximum operating temperature, heating rate, atmosphere control (inert, vacuum, or gas), uniformity of temperature distribution, and safety mechanisms. Additionally, look for user-friendly controls, maintenance requirements, and the furnace’s compatibility with different materials to ensure it meets your specific application needs.

Q5: Can the high-temperature graphitization furnace be used for materials other than PI films?

A5: Yes, the high-temperature graphitization furnace can be used for other carbon-based materials beyond PI films. It is capable of processing various polymers and precursors that require thermal treatment to achieve graphitization. However, it is essential to ensure that the chosen materials are compatible with the furnace’s operational settings for optimal results.

Q6: What are the best practices for maximizing the efficiency of the PI film furnace?

A6: To maximize the efficiency of the PI film furnace, follow these best practices: ensure proper loading of materials to allow for uniform heating, maintain cleanliness within the furnace to avoid contamination, conduct regular calibration of temperature controls, and utilize optimal processing parameters (such as heat-up rates and soak times) specific to the material being graphitized. Regular maintenance of the furnace is also crucial for long-term performance.

Q7: How does high-temperature graphitization affect the properties of PI films?

A7: High-temperature graphitization significantly enhances the properties of PI films, transforming them into high-performance graphite materials. The process increases thermal conductivity, electrical conductivity, and overall mechanical strength, while also improving thermal stability. As a result, graphitized PI films exhibit improved performance in applications requiring high-temperature resistance and conductivity, making them ideal for advanced technology sectors.

Technical Parameter of the 3000 degree PI (Polyimide) Film High-Temperature Graphitization Furnace

| Work Size (mm) | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Volume(L) | 9 | 28 | 125 | 196 | 282 | 452 |

| Heating Power | 100 KW | 160 KW | 200 KW | 250 KW | 300 KW | 350 KW |

| Frequency | 2000 Hz | 2000 Hz | 2000 Hz | 1500 Hz | 1500 Hz | 1500 Hz |

| Max. Work Temperature | 3000°C | |||||

| Ultra Vacuum | 1.2×10-3 mbar | |||||

| Optional High Vacuum | 5×10-5 mbar | |||||

| Max.temperature rise rate | 15°C/min (RT~1500°C), 10°C/min (1500°C~2500°C), 5°C/min (2500°C~3000°C) | |||||

| Vacuum Pressure Rise | 6.7×10-3 mbar/hr | |||||

| Atmosphere | High Vacuum(optional)/ Vacuum/ Inert Gas(Ar or N2)

Vacuum and high vacuum atmospheres are only allowed below 2200°C |

|||||

| Power | 3P, 380V, 50Hz/60Hz | |||||

| Pressure of the cooling water | 1.5~2.5 bar | |||||

| Temperature of the cooling water | ≤28 °C | |||||