Product Description:

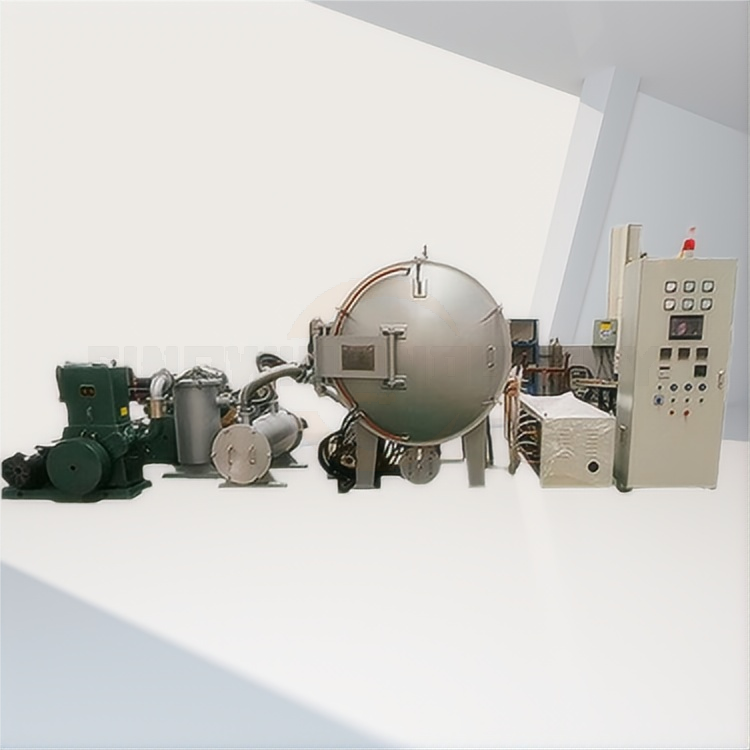

The 2450°C Resistive Silicon Carbide Sintering Furnace is a high-performance industrial furnace used for a variety of applications across several sectors including photovoltaics, electronics, chemicals, and metallurgy. This sophisticated equipment primarily facilitates the preparation of silicon carbide ceramic materials such as ceramic tubes, plates, and electrical power capacitors. Additionally, it is an invaluable tool for laboratory research and the development of new materials, making it indispensable in scientific research environments.This Resistance type silicon carbide sintering furnace designed and produced by nanyang sinowin industry co.ltd operates using intermittent electric heating, focusing on non-pressure silicon carbide ,tungsten carbide powder, chromium carbide powder, titanium carbide powder, and vanadium carbide powder, as well as composite metal powders. After cold pressing, the integrated system expertly handles the sintering process, ensuring optimized material properties.

Key Features:

- Versatile Application The Resistance SiC Sintering Furnace is widely utilized across various industries, including photovoltaic, electronics, chemical, and metallurgy, making it ideal for producing SiC ceramics such as ceramic tubes, boards, and electrical power capacitors.

- Intelligent Control System Equipped with a PID intelligent digital temperature control device, our furnace features programmable multi-segment heating, holding, and cooling curves, which minimizes reading errors and significantly enhances operational efficiency while ensuring safety with over-temperature alarms.

- High-Temperature Insulation Built with durable high-temperature insulation materials, the furnace guarantees long-term operational effectiveness while maintaining external casing temperatures within permissible national standards, ensuring both safety and prolonging the furnace’s lifespan.

- Rapid Heating & Eco-Friendly Designed for fast heating and energy efficiency, the Resistance SiC Sintering Furnace offers precise temperature control and stable performance, making it an environmentally friendly choice for modern laboratories and industrial applications.

- Safety Protocols:The system includes overheating alarms and comprehensive microcomputer control, featuring programmable multi-segment heating, holding, and cooling curves. The resistive silicon carbide sintering furnace can autonomously manage heating, holding, cooling, and overheating protection, automatically halting operations once the program concludes, thereby requiring no on-site supervision.

It is Ideal for professional and research applications where precision and reliability are paramount with our Resistance type silicon carbide sintering furnace to enhance your production capabilities and achieve superior material quality

Technical parameter of our Resistive Silicon Carbide Sintering Furnace:

| Ultimate temperature | 2450℃ |

| Working T. | 2400℃ |

| Ultimate Vacuum | 1Pa(In a cold, empty, and clean furnace chamber.) |

| Leakage rate | Stop the pump for 15 minutes, The cold state should not exceed 10Pa/hour over 12 hours after the 15 minutes stop of the pump |

| Temperature control accuracy | ±1℃ |

| Voltage | 380V、50Hz、3phase |

| Heating materials | Graphite tubes and graphite rods |

| Atmosphere | Ar、N2 |

| Constant temperature zone | 300*300*500mm、400*400*800mm、500*500*1300mm、600*600*1400mm、

800*800*1600mm、1000*1000*2000mm |

Product Q&As for our Resistive Silicon Carbide Sintering Furnace:

Question 1: What is a resistive sintering furnace, and how does it differ from other types of sintering furnaces?

Answer: A resistive sintering furnace is a specialized apparatus designed to facilitate the sintering process through resistive heating elements. Unlike induction or microwave sintering furnaces, which utilize electromagnetic fields, a resistive sintering furnace generates heat directly through resistive materials, allowing for precise control over the temperature profile. This type of furnace is particularly effective for materials like silicon carbide, ensuring uniform heating and optimal density in the final product.

Question 2: How does a resistive sintering furnace work for silicon carbide materials?

Answer: The resistive sintering furnace operates by converting electrical energy into thermal energy using resistive heating elements. For silicon carbide, the furnace is configured to reach high temperatures necessary for sintering. As the heat is applied uniformly, it causes the particles of silicon carbide to bond together, reducing porosity and enhancing mechanical strength. The controlled environment of the furnace also prevents oxidation and promotes the formation of the desired crystalline structures, resulting in high-quality sintered silicon carbide products.

Question 3: What are the advantages of using a resistive sintering furnace for silicon carbide manufacturing?

Answer: The advantages of employing a resistive sintering furnace for silicon carbide include superior temperature control, uniform heating, and reduced energy consumption. This precision facilitates the sintering of silicon carbide to high density and hardness levels, essential for applications in ceramics, electronics, and abrasives. Additionally, the furnace can accommodate various atmospheres and pressures, allowing for versatile processing conditions that enhance the material’s properties.

Question 4: What are the key features to look for in a resistive sintering furnace?

Answer: When selecting a resistive sintering furnace, consider features such as maximum operating temperature, heating elements’ quality, temperature uniformity, and control systems for precise adjustments. Additionally, look for advanced safety features, energy efficiency ratings, and the ability to create specific atmospheres vital for processing silicon carbide. A robust warranty and after-sales support also contribute to a more favorable investment.

Question 5: Can the resistive sintering furnace handle different types of ceramics besides silicon carbide?

Answer: Yes, a resistive sintering furnace is versatile and can handle a variety of ceramic materials aside from silicon carbide. The furnace’s design allows for the adjustment of temperature profiles and atmospheres suitable for different ceramics, including alumina, zirconia, and more. This flexibility makes it an excellent choice for manufacturers looking to sinter various ceramic types while maintaining high quality and efficiency standards.

Whether you’re in the manufacturing sector or a research facility, our Resistive Silicon Carbide Sintering Furnace is an indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with user-friendly operation.

Donot hesitate to Contact us at once for any further information of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Technical parameter of our 2450 degree Resistive Silicon Carbide Sintering Furnace:

| Ultimate temperature | 2450℃ |

| Working T. | 2400℃ |

| Ultimate Vacuum | 1Pa(In a cold, empty, and clean furnace chamber.) |

| Leakage rate | Stop the pump for 15 minutes, The cold state should not exceed 10Pa/hour over 12 hours after the 15 minutes stop of the pump |

| Temperature control accuracy | ±1℃ |

| Voltage | 380V、50Hz、3phase |

| Heating materials | Graphite tubes and graphite rods |

| Atmosphere | Ar、N2 |

| Constant temperature zone | 300*300*500mm、400*400*800mm、500*500*1300mm、600*600*1400mm、

800*800*1600mm、1000*1000*2000mm |