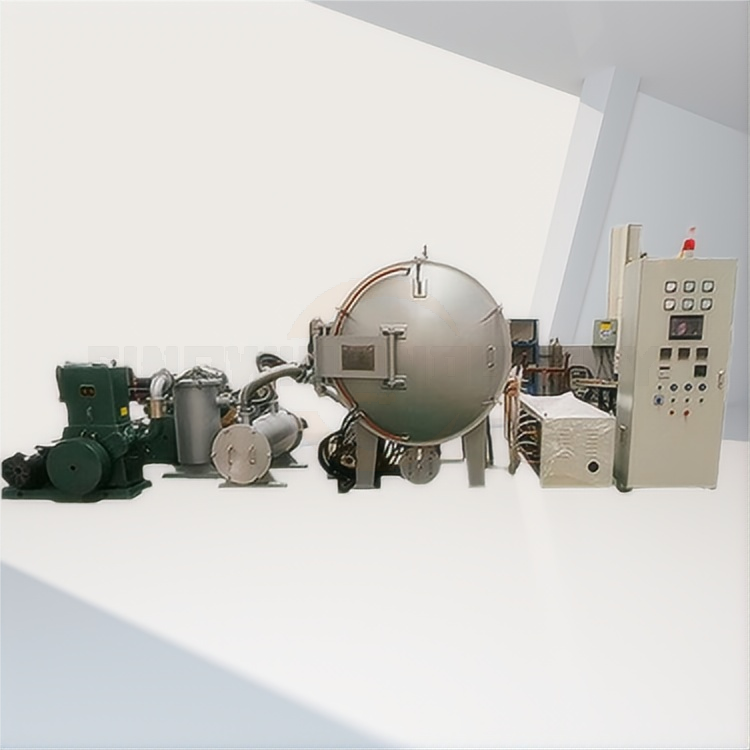

Product Description: 1600 degree Silicon Carbide Deposition Sintering Furnace

The Silicon Carbide Deposition Sintering Furnace, specifically designed for the chemical vapor deposition (CVD) process, optimizing the sintering of carbon-carbon and carbon-ceramic composite materials.

Applications:

This advanced CVD furnace is ideal for the sintering of high-performance composite materials, making it an essential tool in industries focused on innovative materials and applications.

Key Features:

- Horizontal Furnace Body: Our furnace boasts a dual-layer structure with a water-cooling jacket design, ensuring efficient thermal management and safety during operation.

- Advanced Chamber Design: The inner chamber comprises heating elements, insulation layers, thermocouples for temperature measurement, and monitoring thermocouples, creating an integrated system for performance optimization.

- Uniform Heating Elements Arrangement: The heating elements are strategically placed along the furnace’s inner walls to achieve uniform heating, ensuring excellent temperature consistency throughout the application.

- User-Friendly Operation: The furnace is equipped with a PLC and a touch screen or industrial computer for easy operation. It also features an alarm function and high automation, ensuring reliability and safety during use.

Technical Characteristics of the 1600 degree Silicon Carbide Deposition Sintering Furnace

| Work Size W×HXL(mm) | 600×600×1200 | 1000×1000×1200 | 1200×1200×2000 |

| Loading(kg) | 300 | 1000 | 2000 |

| Work Temperature(℃) | 1500 | 1500 | 1500 |

| Temperature Uniformity(℃) | ±7 | ±10 | ±10 |

| Heating Power(kW) | 130 | 300 | 500 |

| Ultra Vacuum(Pa) | 20 | 20 | 20 |

| Pressure Rise Rate(Pa/h) | 0.67 | 0.67 | 0.67 |

Advantages of the 1600 degree Silicon Carbide Deposition Sintering Furnace

- Precise Control Technology: Our furnace utilizes cutting-edge control techniques for accurate management of MTS gas flow and pressure, resulting in stable deposition gas flow with minimal pressure fluctuations within the chamber.

- Specially Designed Deposition Chamber: The deposition chamber features a unique structure that provides excellent sealing and strong anti-contamination capabilities.

- Multi-Channel Gas Flow System: This furnace is designed with a multi-channel gas pathway, ensuring a uniform flow field without deposition dead zones, enhancing the overall deposition effectiveness.

- Efficient Hazardous Gas Treatment: We effectively manage highly corrosive exhaust gases, flammable and explosive gases, solid dust, and low melting-point viscous products generated during the deposition process.

- Newly Designed Corrosion-Resistant Vacuum Unit: Our specially-engineered vacuum unit is built for extended operational periods and boasts a significantly low maintenance rate, reflecting our commitment to durability and performance.

With unparalleled features and advanced technology, our Silicon Carbide Deposition Sintering Furnace offers unmatched reliability and precision for your industrial applications. Whether you are in research, analysis, or manufacturing, the Silicon Carbide Deposition Sintering Furnacesupplied from SINOWIN INDUSTRY is one guaranteed option for your heating treatment industry.

Donot hesitate to Contact us at once for quotation of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Q&A for Silicon Carbide CVD Sintering Furnace

Q1: What is a Silicon Carbide CVD Sintering Furnace, and how does it work?

A1: A Silicon Carbide CVD Sintering Furnace is a specialized equipment used in the process of Chemical Vapor Deposition (CVD) to produce high-purity silicon carbide materials. It works by heating a substrate in a controlled chemical environment where silicon and carbon precursors are vaporized. These vapors react and deposit silicon carbide onto the substrate, allowing for precise control over the material’s properties and structure. This process is essential in manufacturing advanced materials for various high-performance applications.

Q2: How does CVD technology enhance the production of carbon-carbon composites?

A2: CVD technology greatly enhances the production of carbon-carbon composites by providing uniform deposition of carbon materials. This process ensures a much tighter bond between the carbon fibers and the matrix, resulting in improved mechanical properties. Moreover, CVD allows for the tailoring of composite characteristics such as density, porosity, and thermal conductivity, making it a crucial method in producing high-performance carbon-carbon composites suitable for aerospace and automotive applications.

Q3: What are the advantages of using a CVD furnace for sintering ceramic materials?

A3: The use of a CVD furnace for sintering ceramic materials offers several advantages:

- High Purity: CVD processes lead to fewer impurities in the final product due to the controlled environment.

- Precision: The ability to precisely control temperature and chemical composition results in uniform microstructures and better material properties.

- Versatility: CVD technology can be adapted to produce a variety of ceramic materials, thus catering to diverse industrial applications.

- Enhanced Properties: Sintered ceramics exhibit improved mechanical attributes, thermal stability, and resistance to wear when processed through CVD methods.

Q4: Can CVD technology improve the properties of carbon ceramic composites?

A4: Yes, CVD technology significantly improves the properties of carbon ceramic composites. Through the CVD process, a finer microstructure can be achieved, enhancing strength, toughness, and resistance to thermal shock. The uniform deposition of material leads to better interfacial bonding within the composite, which enhances overall performance under extreme conditions. This technology is especially beneficial for applications in aerospace, automotive, and defense sectors, where high-performance materials are crucial.

Q5: What materials can be processed using a Silicon Carbide CVD Sintering Furnace?

A5: A Silicon Carbide CVD Sintering Furnace is capable of processing a wide range of materials, including but not limited to:

- Silicon carbide (SiC) ceramics

- Carbon-carbon composites

- Various advanced ceramic materials such as alumina, zirconia, and nitride-based ceramics

- Specialty materials used in high-temperature environments, such as aerospace components

- —

Please feel free to consult for any additional questions or specifics related to your requirements for the Silicon Carbide CVD Sintering Furnace or Silicon Carbide Deposition Sintering Furnace!

Technical Characteristics of the 1600 degree Silicon Carbide Deposition Sintering Furnace

| Work Size W×HXL(mm) | 600×600×1200 | 1000×1000×1200 | 1200×1200×2000 |

| Loading(kg) | 300 | 1000 | 2000 |

| Work Temperature(℃) | 1500 | 1500 | 1500 |

| Temperature Uniformity(℃) | ±7 | ±10 | ±10 |

| Heating Power(kW) | 130 | 300 | 500 |

| Ultra Vacuum(Pa) | 20 | 20 | 20 |

| Pressure Rise Rate(Pa/h) | 0.67 | 0.67 | 0.67 |