Product Description:

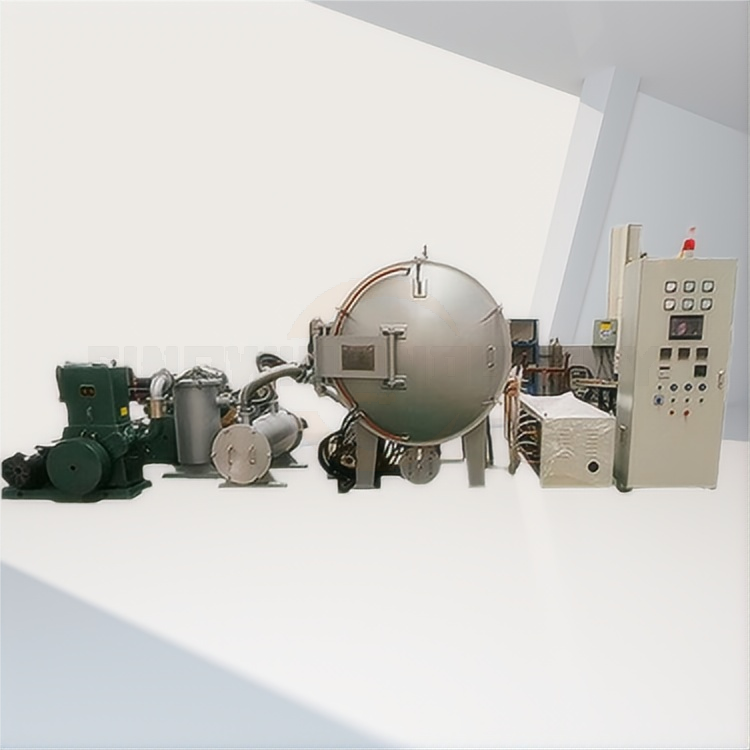

The Silicon Carbide Sintering Furnace – an advanced, batch-type induction heating or resistance heating furnace designed and produced is used for the production of various granular tungsten carbide, titanium carbide, vanadium carbide powders, and composite metal powders in the hard alloy and powder metallurgy industries. This furnace offers unparalleled capabilities for vacuum sintering, partial pressure sintering, micro positive pressure sintering, reactive sintering, pressureless sintering, recrystallization sintering, and hot isostatic pressing of composite materials including silicon carbide, carbon/carbon composites, transparent ceramics, and carbon ceramics.

Overview of Features:

- The furnace operates at a maximum temperature of up to 2400°C, enabling a wide range of sintering applications with high efficiency.

- Equipped with a specialized resin removal and dust collection system, the furnace is capable of executing a complete resin removal sintering process in one cycle, ensuring cleaner and more efficient operations.

Applications:

The Silicon Carbide Sintering Furnace is ideally suited for:

- Pressureless sintering of boron carbide ceramics

- Pressureless sintering of silicon carbide ceramics

- Recrystallization sintering of silicon carbide ceramics

- Sintering of aluminum nitride ceramics

- Sintering high-performance ceramic substrates

- Precision ceramic sintering for products requiring strict consistency in shrinkage dimensions and density

- High-temperature vacuum sintering of metallurgical powders and other metallic and non-metallic materials

Key Features:

- High Automation: The furnace boasts a high level of automation with one-button replacement capability for vacuum extraction and argon gas flushing processes. The entire operation, including water, electricity, and gas, is monitored automatically, with a user-friendly touch screen interface enabling real-time observation of device status, alarm indications, temperature curves, and operational commands.

- Robust Construction: Constructed entirely from high-quality 304 stainless steel in compliance with pressure vessel standards, our furnace offers excellent corrosion resistance and sealing performance. The insulation materials are composed of high-purity graphite felt, ensuring long-lasting durability. All electrical components are sourced from reliable domestic and international brands for dependable operation.

- Enhanced Safety: The furnace features an automatic explosion-proof valve for added safety and reliability. The induction sensor is fitted with a dedicated flow switch to continuously monitor water flow conditions, while power supply parameters are stringently set to predefined overload and over-voltage thresholds.

- Optional Accessories: The device can be equipped with a dedicated medium-frequency power supply circulation cooling system and a protective gas purification unit. The circulation cooling system effectively minimizes equipment malfunctions caused by cooling water quality issues, ensuring sustained, high-performance production. Moreover, the protective gas purification device guarantees a high level of purity for the protective gas, extending the lifespan of the furnace’s insulation materials and reducing overall customer costs.

Technical Parameter:

| Work Size | m | 300*300*400 | 450*450*750 | 500*500*1200 | 600*600*1500 | 700*700*1500 | 800*800*2000 | |

| Heating Method | / | Resistance Heating/IGBT Heating | ||||||

| Ultra Vacuum | Pa | 6.6X10ˉ3 | ||||||

| Working Temperature | ℃ | 2400 | 2400 | 2400 | 2400 | 2400 | 2400 | |

| Max.Temperature | ℃ | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | |

| Atmosphere | / | High Vacuum (optional),Vacuum/N²、Ar etc. | ||||||

Q&A for Silicon Carbide (SiC) Sintering Furnace

Q1: What is a Silicon Carbide (SiC) Sintering Furnace, and how does it work?

A1: A Silicon Carbide Sintering Furnace is a specialized device designed for high-temperature processing of SiC materials. It operates by utilizing advanced heating systems to achieve precise temperature control, facilitating the densification of SiC powder into solid components. The furnace features an airtight structure and high-vacuum replacement systems that ensure the purity of gases, thus enhancing the quality of the final products. This process is essential for creating durable materials used across various industries.

Q2: What are the advantages of using an SiC Sintering Furnace in production?

A2: Using an SiC Sintering Furnace offers several advantages, including excellent thermal stability, high efficiency with heating rates up to 600°C/h, and a significant reduction in production cycles. The high purity environment maintained by the furnace protects the product from contamination, resulting in superior material properties. It is specifically designed to meet the demanding requirements for advanced material processing, making it a valuable asset in production.

Q3: How does temperature affect the sintering process of Silicon Carbide?

A3: Temperature plays a critical role in the sintering process of Silicon Carbide. Elevated temperatures facilitate the diffusion processes that lead to densification and improved material strength. However, achieving optimal temperatures is crucial; higher than necessary temperatures can lead to excessive grain growth or even decomposition of the material. Therefore, precise control of temperature is essential to achieve the best performance from SiC components, which the advanced controls of our furnace ensure.

Q4: What factors should be considered when choosing a Silicon Carbide Sintering Furnace?

A4: When selecting a Silicon Carbide Sintering Furnace, key factors to consider include maximum operating temperature, furnace capacity, heating rate, and the purity level of the atmosphere within the furnace. Additionally, energy efficiency, ease of maintenance, and the reputation of the manufacturer should also be taken into account. These elements will influence not only the performance and output quality but also the overall operational costs of the furnace.

Q5: How can I improve the efficiency of my Silicon Carbide Sintering Furnace?

A5: To enhance the efficiency of your Silicon Carbide Sintering Furnace, consider optimizing the heating rate by utilizing advanced control systems, ensuring that thermal insulation is intact to reduce heat loss, and maintaining regular maintenance checks to prevent operational downtimes. Additionally, employing software solutions for monitoring and adjustments can significantly streamline processes, resulting in shorter production cycles and better energy utilization.

Q6: Which industries benefit from using a Silicon Carbide Sintering Furnace?

A6: Various industries significantly benefit from the use of Silicon Carbide Sintering Furnaces, including aerospace, automotive, electronics, and materials science. In aerospace, SiC parts are crucial for high-temperature applications. The automotive industry utilizes SiC for components that require high thermal conductivity. Electronics benefit from its application in semiconductors. Overall, any field that demands high-performance ceramics can leverage the capabilities of SiC sintering furnaces.

Q7: Are there environmental considerations when using a Silicon Carbide Sintering Furnace?

A7: Yes, there are several environmental considerations when operating a Silicon Carbide Sintering Furnace. The high-energy consumption associated with sintering processes can lead to increased carbon footprints; therefore, using energy-efficient systems and renewable energy sources can mitigate these effects. Additionally, ensuring proper emissions control and gas management within the furnace helps minimize any potential pollutants released into the atmosphere, aligning with sustainability practices.

Please feel free to consult for any additional questions or specifics related to your requirements for the Silicon Carbide Sintering Furnace.

The Silicon Carbide Sintering Furnace is the ultimate solution for those seeking efficiency, safety, and superior material processing capability in high-temperature heat treatment industry. Whether you are in research, analysis, or manufacturing, the Silicon Carbide Sintering Furnace supplied from SINOWIN INDUSTRY is one guaranteed option for your heating treatment industry.

Donot hesitate to Contact us at once for quotation of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Technical Parameter of the 2400 degree Silicon Carbide Sintering Furnace :

| Work Size | m | 300*300*400 | 450*450*750 | 500*500*1200 | 600*600*1500 | 700*700*1500 | 800*800*2000 | |

| Heating Method | / | Resistance Heating/IGBT Heating | ||||||

| Ultra Vacuum | Pa | 6.6X10ˉ3 | ||||||

| Working Temperature | ℃ | 2400 | 2400 | 2400 | 2400 | 2400 | 2400 | |

| Max.Temperature | ℃ | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | |

| Atmosphere | / | High Vacuum (optional),Vacuum/N²、Ar etc. | ||||||