Product Description:

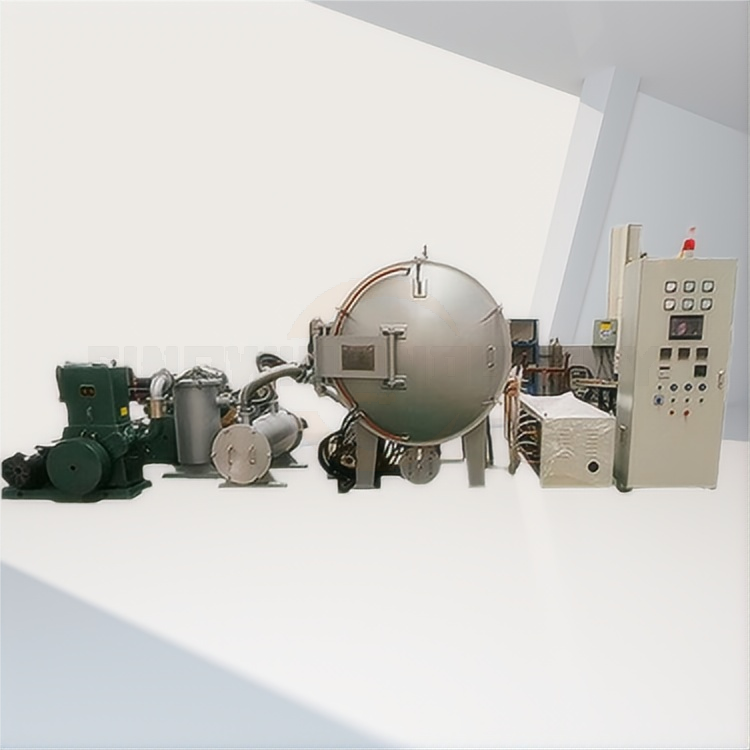

The **Silica Sintering Furnace**, is used for the mass sintering production of battery anode materials, silica, and various gas-phase deposition materials. This state-of-the-art equipment features a horizontal dual-door high vacuum sintering system that optimizes efficiency and output in high-temperature applications.

Key Features:

– High Production Efficiency:

The furnace is capable of handling a significant batch load, enabling substantial production runs with minimal downtime.

– Multi-Zone Heating:

Our furnace utilizes multi-zone heating technology, providing precise temperature control of up to 1500 degrees Celsius. Experience rapid heating rates that enhance your material preparation processes.

– Stable Vacuum Operation:

Designed for reliable performance, this furnace can maintain stable operating conditions under high vacuum, ensuring the quality of your silica and other materials.

The **Silicon Oxide Sintering Furnace** is perfect designed and supplied by Sinowin Industry for the high-temperature fabrication and collection of silica materials, including silicon monoxide, to enhance your production while maintaining superior quality standards.

Technical Parameter of Silicon Oxide Sintering Furnace:

| Furnace structure | Horizontal |

| Thermostatic area size | Φ500mm*600mm、φ600mm*800mm、φ700mm*1000mm、

Φ800mm*1600mm(Size Customizable) |

| Max.work termperature | 2400°C |

| Optimal temperature | When The temperature is controlled within 1500 degrees, the heating rate is the fastest |

| Furnace body | With an inner and outer double-layer water cooling structure, the parts that come into contact with the cooling water are made of 304 stainless steel, effectively preventing gas leakage from the furnace body after long-term use. |

| Sublimation system | Composed of a heating zone and a collection zone, the heating zone consists of an induction coil, heavy-duty corundum, graphite felt, and isostatic graphite; the collection zone is made up of 310S stainless steel and an insulation layer. |

| Temperature control system | Adopting PLC touch screen centralized control method, automatic control, with network port, can achieve remote control. |

| Heating system | Adopting induction heating, the power supply uses an IGBT energy-saving power source, which has low noise and is about 15% more energy-efficient than traditional thyristor power sources |

| Vacuum system | Composed of multistage vacuum pumps, vacuum valves, pressure controllers, and piping. |

| ·Cooling System

|

Configure a closed cooling system, use deionized water for the internal loop to prevent scaling in the equipment pipes, with minimal internal water loss. The external loop uses tap water with automatic water replenishment and fans that start up automatically for cooling; it has good heat dissipation, integrated environmental protection, and a small footprint. |

| The equipment consists of sublimation system, collection system, heating system, temperature control system, vacuum system, mechanical system and cooling system.。 | |

Whether you’re in the manufacturing sector or a research facility, our Silicon Oxide Sintering Furnace is an indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with user-friendly operation.

Donot hesitate to Contact us at once for any further information of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Q&A for Silicon Oxide Sinter Furnace :

Q1: What are the advantages of using a Silicon Oxide Sinter Furnace for industrial sintering applications?

**A1:** The Silicon Oxide Sinter Furnace offers numerous advantages for industrial sintering applications, making it an ideal choice for manufacturers. First and foremost, it provides a high-temperature environment that is crucial for achieving uniform sintering of materials, ensuring optimal density and strength. Additionally, its advanced temperature control systems allow for precise management of thermal profiles, reducing the risk of defects during the sintering process. This furnace is also highly efficient, leading to lower energy consumption and cost savings. Furthermore, silicon oxide is known for its excellent thermal stability and resistance to chemical reactions, which means a longer lifespan for the furnace and reduced maintenance costs. Overall, investing in a Silicon Oxide Sinter Furnace can significantly enhance product quality and operational efficiency in your production line.

—

Q2: Can the Silicon Oxide Sinter Furnace be used for various materials?

**A2:** Yes, the Silicon Oxide Sinter Furnace is highly versatile and can be utilized for a wide range of materials, including ceramics, metals, and composites. Its ability to reach and maintain high temperatures, combined with precise control over the sintering atmosphere, allows for effective processing of different materials with varying thermal properties. This flexibility makes it an excellent choice for industries such as ceramics, aerospace, and electronics, where diverse material requirements are common. Whether you’re sintering hard ceramics or metal powders, the Silicon Oxide Sinter Furnace is designed to deliver consistent and reliable results across various applications.

—

Q3: What operational features should I expect from a Silicon Oxide Sinter Furnace?

**A3:** When utilizing a Silicon Oxide Sinter Furnace, you can expect an array of operational features that enhance usability and performance. Key features include advanced digital control systems for precise temperature management, programmable sintering profiles, and real-time monitoring capabilities. Many models come equipped with high-quality insulation to minimize heat loss and improve energy efficiency. Additionally, some furnaces may offer adjustable atmospheres, allowing you to tailor the sintering environment according to material requirements. With these features, the Silicon Oxide Sinter Furnace not only streamlines production processes but also helps maintain the highest standards of quality in your industrial applications.

—

Q4: Is the Silicon Oxide Sinter Furnace energy-efficient?

**A4:** Absolutely, the Silicon Oxide Sinter Furnace is designed with energy efficiency in mind. It incorporates advanced insulation materials and high-performance heating elements that minimize energy waste while providing optimal heat transfer. The precise temperature control capabilities allow for only the necessary energy input based on the specific sintering profile, which collectively leads to lower operational costs. Investing in an energy-efficient sintering furnace not only helps your bottom line but also contributes to more sustainable manufacturing practices by reducing overall energy consumption.

—

Q5: How does the Silicon Oxide Sinter Furnace ensure product quality?

**A5:** The Silicon Oxide Sinter Furnace is engineered to ensure exceptional product quality through several key mechanisms. Its high-temperature capabilities allow for optimal densification of materials, which is critical in minimizing porosity and enhancing structural integrity. The precise control over sintering parameters—such as temperature, time, and atmosphere—further guarantees that each batch achieves uniform results. Moreover, the furnace’s reliable thermal uniformity prevents hotspots and cold spots, which could lead to defects in the final product. As a result, manufacturers can trust that employing a Silicon Oxide Sinter Furnace will yield consistently high-quality materials suitable for demanding industrial applications.

Please feel free to consult for any additional questions or specifics related to your requirements for our Silicon Oxide Sinter Furnace.