**Product Description:**

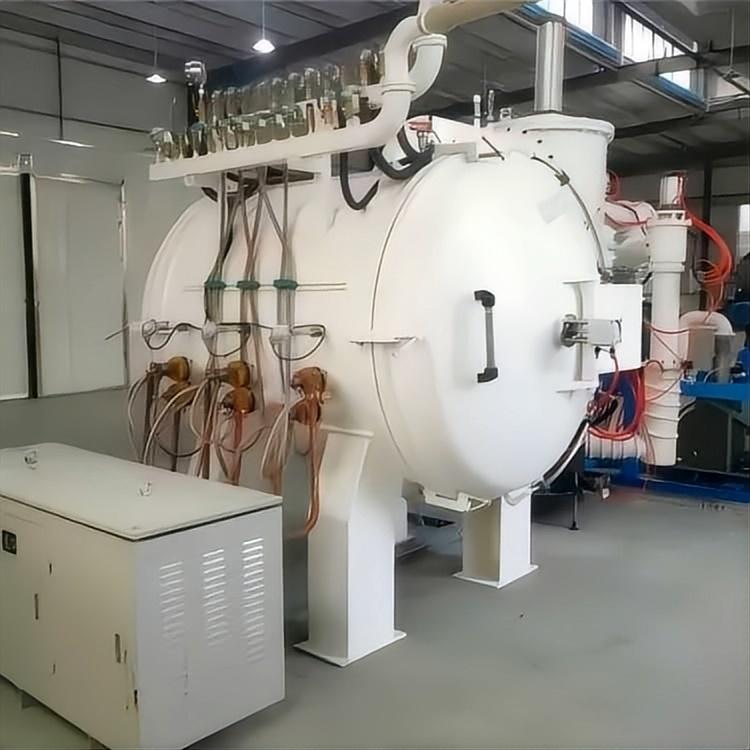

The High-Temperature Graphite Powder Purification Furnace , a cutting-edge solution engineered for the effective high-temperature physical purification of various graphite types, including flake graphite powder, coal-based graphite powder, earthy graphite powder, and carbon nanotubes. This furnace is expertly designed to process raw materials with a carbon content of ≥ 98%, making it an ideal choice for industries that demand high purity graphite.

**Key Features:**

- **High Operating Temperature:** The furnace operates at extraordinary temperatures, reaching up to 3000℃ for short durations and maintaining an impressive 2900℃ for extended use.

- **Environmentally Friendly:** Utilizing a physical high-temperature purification method, this furnace works without the use of acids, ensuring no environmental pollution occurs during the purification process.

- **Superior Sealing:** The equipment boasts excellent sealing capabilities with a fully enclosed structure. It is equipped with a vacuum pumping system and an argon gas replacement system that safeguards the gas purity inside the furnace.

- **Energy Efficient:** Featuring electromagnetic induction heating technology, our furnace directly heats the graphite crucible, optimizing thermal efficiency and resulting in significant energy savings.

- **Rapid Heating Rate:** The furnace can achieve heating rates of up to 600℃/h, with even faster rates at lower temperatures, ensuring quick processing times.

- **Short Production Cycle:** The time from loading to unloading the furnace is remarkably short, typically between 24 to 36 hours, making it highly efficient for production demands.

- **Precise Temperature Control:** Employing infrared temperature measurement technology and PID segmented program control, the furnace ensures accurate temperature control with minimal error margin.

- **High Safety Standards:** Designed with safety in mind, the furnace features a double-layer stainless steel shell with water-cooling in the interlayer, keeping the outer shell temperature below 50℃. It is also fitted with pressure, water, and high-temperature alarms, along with an overpressure venting device.

- **Tail Gas Filtration System:** Our furnace is equipped with a dedicated tail gas filtration device to ensure compliance with safety and environmental standards.

**Parameter of the High-Temperature Graphite Powder Purification Furnace **

| Work Size -DXH(mm) | Ф400X800 | Ф500X1000 | Ф600X1200 | Ф800X1200 | Ф900X1200 |

| Volume(L) | 100 | 196 | 339 | 602 | 763 |

| Work Temperature(℃) | 3000 | 3000 | 2850 | 2850 | 2850 |

| Temperature Uniformity(℃) | ±15 | ±15 | ±15 | ±20 | ±20 |

| Voltage(V) | 3 phase,380 | ||||

| Power(KW) | 200 | 250 | 300 | 400 | 450 |

| Atmosphere |

Vacuum /Ar,N2 etc.,Inert atmosphere |

||||

Invest in the High-Temperature Purification Furnace for Graphite Powder today and elevate your purification processes with unmatched efficiency, safety, and environmental responsibility. Perfect for industries requiring the utmost purity in graphite materials, our furnace is your solution for high-quality results every time.Whether you are in research, analysis, or manufacturing, the High-Temperature Purification Furnace for Graphite Powder supplied from SINOWIN INDUSTRY is your best choice.Donot hesitate to Contact us today for a quote and transform your scientific journey completely.

Q&As of our high-temperature purification furnace for graphite powder:

### Q1: What is a High-Temperature Purification Furnace for Graphite Powder?

**A:** A High-Temperature Purification Furnace is a specialized equipment designed to purify graphite powder by using elevated temperatures to remove impurities. The process involves heating the graphite to high temperatures, facilitating the breakdown of contaminants and enhancing the overall purity of the material. This furnace is essential for industries requiring high-purity graphite for advanced applications.

—

### Q2: How does a High-Temperature Furnace increase the purity of graphite?

**A:** A High-Temperature Furnace increases graphite purity by subjecting the material to temperatures where impurities decompose or oxidize, which leads to their removal. The controlled environment within the furnace ensures that the graphite maintains its structural integrity while achieving high levels of purity, often exceeding 99.9%. This precision is vital for applications demanding exceptional material quality.

—

### Q3: What are the benefits of using a purification furnace for processing graphite powder?

**A:** The benefits of using a purification furnace for graphite powder include significantly enhanced material purity, improved electrical and thermal conductivity, and extended lifespan of the purified graphite in applications. Additionally, it allows manufacturers to meet industry standards, thus increasing product reliability and market competitiveness. The overall process results in superior performance in critical applications.

—

### Q4: What temperature is needed for effective purification of graphite powder?

**A:** Effective purification of graphite powder typically requires temperatures between 2000°C to 3000°C, depending on the level of impurities present and the desired purity level. Operating within this temperature range facilitates the dissociation of unwanted contaminants while preserving the structural properties of graphite, ensuring optimal results.

—

### Q5: How do I choose the appropriate high-temperature furnace for graphite processing?

**A:** When selecting a high-temperature furnace for graphite processing, consider factors such as temperature range, heating capacity, chamber size, and control features. Ensure the furnace is constructed from high-quality, heat-resistant materials and offers uniform heating capabilities to guarantee consistent results. Additionally, assess manufacturer reputation and customer support, as these will contribute to operational efficiency and reliability.

—

### Q6: Which applications require highly purified graphite powder?

**A:** Highly purified graphite powder is crucial for various applications, including the production of batteries, electronics, fuel cells, and advanced materials. Industries such as aerospace, automotive, and energy require high-purity graphite for components that demand exceptional performance under extreme conditions. The metallurgical, nuclear, and semiconductor sectors also benefit significantly from high-quality graphite.

—

### Q7: What safety hazards are associated with using a high-temperature furnace for graphite purification?

**A:** Using a high-temperature furnace involves potential safety hazards such as exposure to extreme temperatures, which can lead to burns or fire. Additionally, gases generated during the purification process may be harmful if inhaled. It’s imperative to operate the furnace within safety guidelines, employing protective gear, ensuring proper ventilation, and integrating appropriate monitoring systems to mitigate risks effectively. Always consult the manufacturer’s safety manual and follow recommended practices.