Product Description:

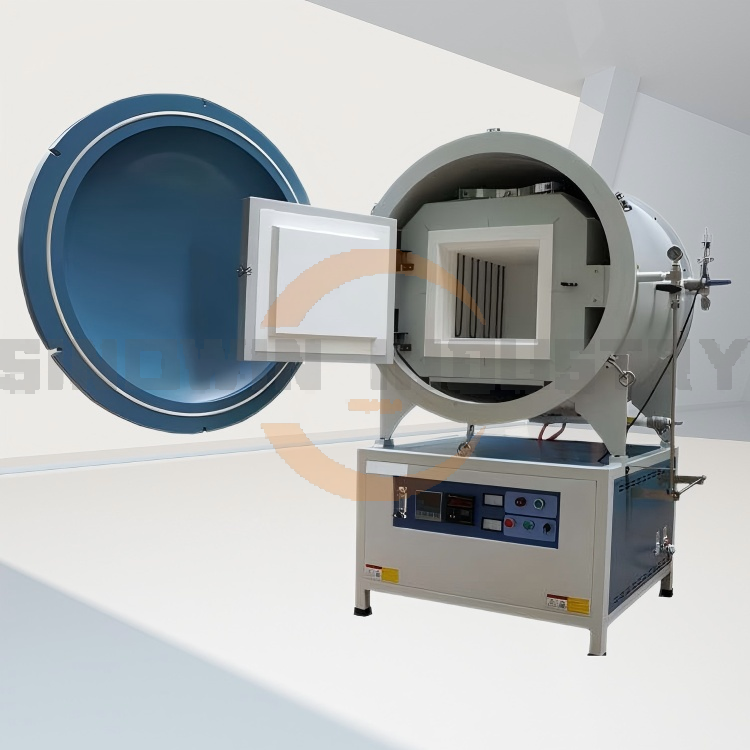

The Vacuum Atmosphere Box Type Resistance Furnace is an advanced thermal processing solution used for the heat treatment of metal materials under low vacuum, reducing, and protective atmospheres. This furnace is also ideal for the thermal treatment of special materials, such as carbon products during the carbonization process.

Parameter of the Vacuum Atmosphere Box Type Resistance Furnace:

| Temperature | 900°C/1000°C, 1100°C/1200°C , 1300°C/1400°C , 1600°C/1700°C |

| Temperature control mode | 30 programmable automatic temperature control, intelligent program fuzzy PID control |

| Heating rate | 0-20oC/ min |

| Temperature control accuracy | Temperature control accuracy +/- 1°C |

| Heating element | Resistance wire/Sic/MoSi2 |

| The furnace structure | vacuum pressure tank, the furnace door is sealed with silicone ring, and the furnace shell is equipped with water cooling system |

| Furnace lined with alumina fiber | |

| Cold vacuum | low vacuum 10Pa; High vacuum 0.07Pa |

| Hot vacuum | Low vacuum 100Pa; High vacuum 0.7Pa-0.07Pa |

| Hot pressure rise rate | 40pa/h |

900°C/1000°C Vacuum Resistance Furnace |

||||||||

| Work Size | Vacuum(cool status) | Vacuum(Hot status) | Ultra Temperatiure | Work Temperature | Power | Voltage | Heating Element | Temperature measuring element |

| 100*100*100 | 0.0067 Pa | 0.067 Pa | 1000℃ | 900℃ | 1 KW | 1 Phase 220V | Resistance wire | K type |

| 200*150*150 | 0.0067 Pa | 0.067 Pa | 1000℃ | 900℃ | 3 KW | 1 Phase 220V | Resistance wire | K type |

| 300*200*200 | 0.0067 Pa | 0.067 Pa | 1000℃ | 900℃ | 4 KW | 1 Phase 220V | Resistance wire | K type |

| 400*300*300 | 0.0067 Pa | 0.067 Pa | 1000℃ | 900℃ | 9 KW | 3Phase 380V | Resistance wire | K type |

| 500*400*400 | 0.0067 Pa | 0.067 Pa | 1000℃ | 900℃ | 15 KW | 3Phase 380V | Resistance wire | K type |

1100°C/1200°C Vacuum Resistance Furnace |

||||||||

| Work Size | Vacuum(cool status) | Vacuum(Hot status) | Ultra Temperatiure | Work Temperature | Power | Voltage | Heating Element | Temperature measuring element |

| 100*100*100 | 0.0067 Pa | 0.067 Pa | 1200℃ | 1100℃ | 1 KW | 1 Phase 220V | Resistance wire | K type |

| 200*150*150 | 0.0067 Pa | 0.067 Pa | 1200℃ | 1100℃ | 3 KW | 1 Phase 220V | Resistance wire | K type |

| 300*200*200 | 0.0067 Pa | 0.067 Pa | 1200℃ | 1100℃ | 4 KW | 1 Phase 220V | Resistance wire | K type |

| 400*300*300 | 0.0067 Pa | 0.067 Pa | 1200℃ | 1100℃ | 9 KW | 3Phase 380V | Resistance wire | K type |

| 500*400*400 | 0.0067 Pa | 0.067 Pa | 1200℃ | 1100℃ | 15 KW | 3Phase 380V | Resistance wire | K type |

1300°C/1400°C Vacuum Resistance Furnace |

||||||||

| Work Size | Vacuum(cool status) | Vacuum(Hot status) | Ultra Temperatiure | Work Temperature | Power | Voltage | Heating Element | Temperature measuring element |

| 100*100*100 | 0.0067 Pa | 0.067 Pa | 1400℃ | 1300℃ | 2 KW | 1phase 220V | Sic | S type |

| 200*150*150 | 0.0067 Pa | 0.067 Pa | 1400℃ | 1300℃ | 4 KW | 1 phase 220V | Sic | S type |

| 300*200*200 | 0.0067 Pa | 0.067 Pa | 1400℃ | 1300℃ | 7 KW | 1 phase 220V | Sic | S type |

| 400*300*300 | 0.0067 Pa | 0.067 Pa | 1400℃ | 1300℃ | 12 KW | 3 phase 380V | Sic | S type |

| 500*400*400 | 0.0067 Pa | 0.067 Pa | 1400℃ | 1300℃ | 18 KW | 3phase 380V | Sic | S type |

| 600*600*600 | 0.0067 Pa | 0.067 Pa | 1400℃ | 1300℃ | 40 KW | 3phase 380V | Sic | S type |

| 800*800*800 | 0.0067 Pa | 0.067 Pa | 1400℃ | 1300℃ | 60 KW | 3phase 380V | Sic | S type |

| 900*900*900 | 0.0067 Pa | 0.067 Pa | 1400℃ | 1300℃ | 80 KW | 3phase 380V | Sic | S type |

1600°C/1700°C Vacuum Resistance Furnace |

||||||||

| Work Size | Vacuum(cool status) | Vacuum(Hot status) | Ultra Temperatiure | Work Temperature | Power | Voltage | Heating Element | Temperature measuring element |

| 100*100*100 | 0.0067 Pa | 0.067 Pa | 1700℃ | 1600℃ | 1 KW | 1phase 220V | MoSi2 | B type |

| 200*150*150 | 0.0067 Pa | 0.067 Pa | 1700℃ | 1600℃ | 4 KW | 1phase 220V | MoSi2 | B type |

| 300*200*200 | 0.0067 Pa | 0.067 Pa | 1700℃ | 1600℃ | 7 KW | 1phase 220V | MoSi2 | B type |

| 400*300*300 | 0.0067 Pa | 0.067 Pa | 1700℃ | 1600℃ | 16 KW | 3phase 380V | MoSi2 | B type |

| 500*400*400 | 0.0067 Pa | 0.067 Pa | 1700℃ | 1600℃ | 25 KW | 3phase 380V | MoSi2 | B type |

| 600*600*600 | 0.0067 Pa | 0.067 Pa | 1700℃ | 1600℃ | 50 KW | 3phase 380V | MoSi2 | B type |

| 800*800*800 | 0.0067 Pa | 0.067 Pa | 1700℃ | 1600℃ | 90 KW | 3phase 380V | MoSi2 | B type |

| 900*900*900 | 0.0067 Pa | 0.067 Pa | 1700℃ | 1600℃ | 120 KW | 3phase 380V | MoSi2 | B type |

Key Features:

- – **Innovative Structure**: The furnace is built with an external sealed vacuum chamber that meets rigorous vacuum requirements. Its novel design ensures ease of operation and maintenance.

- – **Heating Elements**: Utilizing high-quality resistance wire, the furnace’s heating elements guarantee effective and consistent heating.

- – **Advanced Temperature Control**: Featuring a multi-segment intelligent program temperature control system, this furnace achieves remarkable temperature stability and repeatability. The temperature control offers a programmable automatic regulation with 30 segments, utilizing an intelligent fuzzy PID control mechanism.

- – **Heating Rate**: The furnace boasts a heating rate of up to 0-20°C per minute.

- – **Precision Control**: The temperature control accuracy is within +/- 1°C, ensuring precise thermal processing for sensitive applications.

- – **Robust Construction**: The furnace body comprises a vacuum pressure tank, equipped with a silicone seal on the door, and features a water cooling system for optimal thermal management.

- – **Insulation Material**: Lined with high-performance alumina fiber, the furnace ensures efficient heat retention.

- – **Vacuum Systems**:

- – **Cold Vacuum**: Achieves low vacuum at 10 Pa and high vacuum down to 0.07 Pa.

- – **Hot Vacuum**: Operates at low vacuum levels of 100 Pa and can sustain high vacuum reaching from 0.7 Pa to 0.07 Pa.

- – **Pressure Rise Rate**: Maintains a pressure rise rate of just 40 Pa/h, ensuring minimal contamination and maximum efficiency.

- – **Low Vacuum System**: Equipped with a dual-stage rotary vane mechanical vacuum pump with a power output of 6 kW and a pumping speed of 70 L/s. It includes a KF60 interface, digital vacuum gauge, manual gate valve, and vacuum corrugated pipe for reliable operation.

- – **High Vacuum System**: Enhanced with a dual-stage rotary vane pump coupled with a diffusion pump, along with a digital vacuum gauge, manual gate valve, and appropriate connections for effective vacuum management.

- – **Gas Inlet**: The gas filling is regulated using manua valves with a KF16 interface, allowing for controlled atmosphere adjustments.

The Vacuum Atmosphere Box Type Resistance Furnace epitomizes industry standards in thermal processing technology. Whether for metal materials or specialized compounds, it guarantees reliability and performance in various applications, making it an essential tool for your manufacturing or research needs.

Please feel free to consult for any additional questions or specifics related to your requirements for the vacuum atmosphere box resistance furnaces.

### Q&A for Vacuum Atmosphere Box Resistance Furnace

**Q1: What is the purpose of a vacuum atmosphere box resistance furnace?**

**A1:** The vacuum atmosphere box resistance furnace is designed for sintering, heat treatment, and other high-temperature processes in a controlled environment. It is particularly useful for materials that require processing in a vacuum to prevent oxidation or contamination, making it ideal for advanced materials like ceramics, metals, and semiconductors.

—

**Q2: How does a vacuum atmosphere furnace work?**

**A2:** The vacuum atmosphere furnace operates by creating a controlled low-pressure environment that significantly reduces the presence of gases. This is achieved through a vacuum pump that evacuates air from the chamber. Once the desired vacuum level is reached, the furnace applies heat through electric resistance elements, allowing for precise temperature control during material processing.

—

**Q3: What are the benefits of using a box resistance furnace?**

**A3:** Using a box resistance furnace offers numerous advantages such as enhanced material quality, improved process consistency, and minimized risk of oxidation and contamination. The ability to control the atmosphere allows for better sintering results and the processing of sensitive materials, ultimately leading to higher-quality output.

—

**Q4: What materials can be processed in a vacuum atmosphere furnace?**

**A4:** A vacuum atmosphere furnace can process a wide range of materials including metals (like titanium and stainless steel), ceramics, glass, and composite materials. It is particularly advantageous for high-value materials and those that require specific environmental conditions to achieve optimal properties.

—

**Q5: How can I improve the efficiency of my vacuum atmosphere box resistance furnace?**

**A5:** To enhance the efficiency of your vacuum atmosphere box resistance furnace, ensure proper maintenance by regularly cleaning the chamber and checking for any leaks. Optimize your process parameters, including temperature and heating time, and make use of proper loading techniques to maximize space and heat distribution. Additionally, consider upgrading insulation to reduce heat loss and increase energy efficiency.

—

**Q6: What safety precautions should be taken when using a vacuum furnace?**

**A6:** When operating a vacuum furnace, it’s essential to wear appropriate personal protective equipment (PPE) such as heat-resistant gloves and safety goggles. Regularly inspect the furnace for any signs of wear or malfunction, and ensure that emergency shut-off systems are in place. Always follow the manufacturer’s operating guidelines and provide training for all personnel involved in the furnace operation.

—

**Q7: What is the difference between a vacuum furnace and a traditional furnace?**

**A7:** The primary difference between a vacuum furnace and a traditional furnace is the operating atmosphere. A vacuum furnace operates in a controlled vacuum environment, minimizing ambient gases, which significantly reduces oxidation and contamination risks. In contrast, traditional furnaces typically operate in atmospheric conditions, which can introduce impurities and limit material processing capabilities.

—

**Q8: Where can I find reliable manufacturers of vacuum atmosphere box resistance furnaces?**

**A8:** To find reliable manufacturers of vacuum atmosphere box resistance furnaces, consider searching industry directories, trade shows, and online marketplaces specializing in industrial equipment. Look for manufacturers with a proven track record, positive customer reviews, and a commitment to quality assurance. You can also reach out to industry associations for recommendations on reputable suppliers.

Whether you’re in the manufacturing sector or a research facility, our vacuum atmosphere box resistance furnaces is an indispensable furnace and one guaranteed option for your heating treatment industry that combines cutting-edge technology with user-friendly operation.

Donot hesitate to Contact us at once for any further information of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .