Product Description:

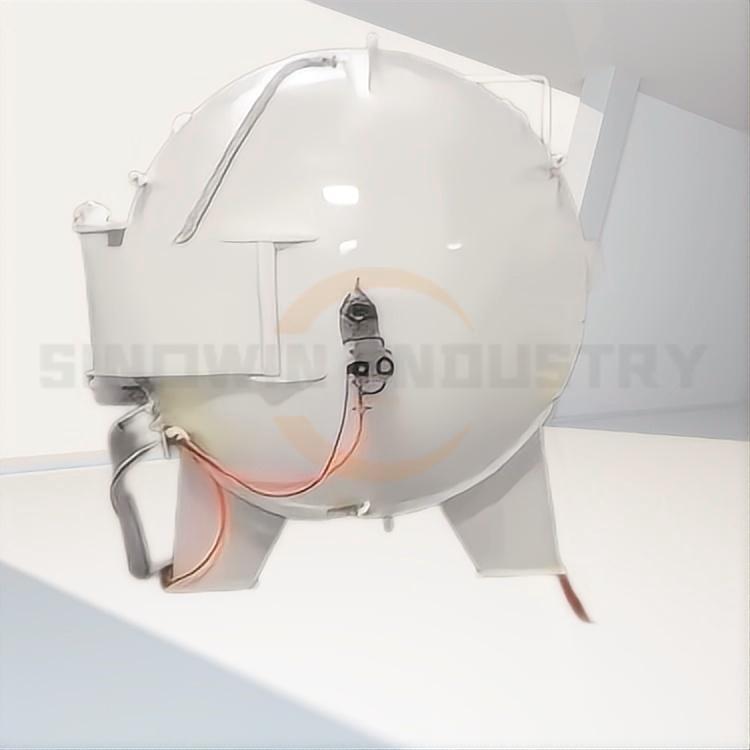

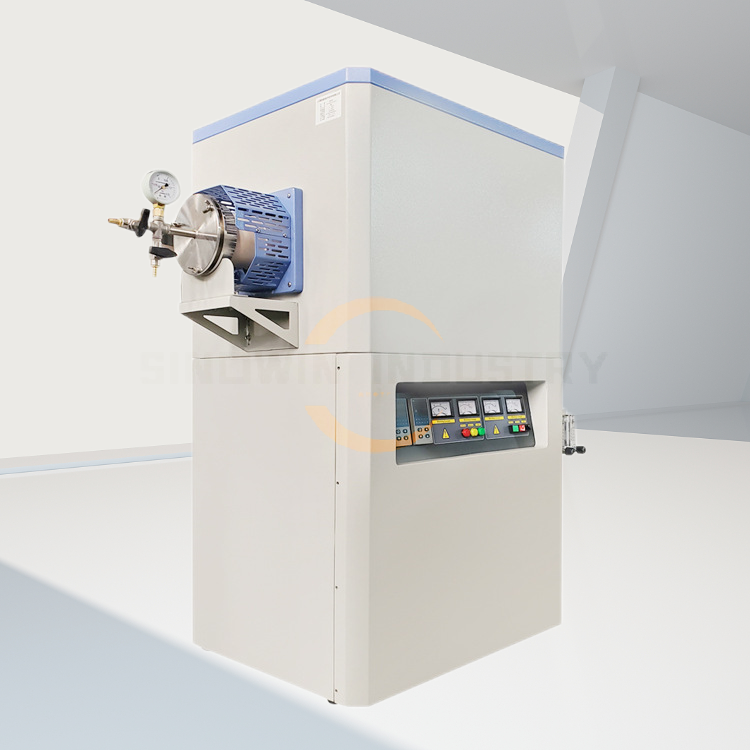

The Vacuum Brazing Furnace is a sophisticated piece of machinery designed for the heating of workpieces within a vacuum chamber, making it ideal for applications demanding high-quality soldering, particularly for materials that are prone to oxidation. This innovative furnace utilizes copper brazing wire that melts during the heating process to achieve effective welding. Its versatility allows it to connect not only similar materials but also dissimilar materials, significantly broadening the range of applicable materials.

Key Features:

- Efficient Heating Element Design: The furnace is equipped with a well-distributed heating element layout that provides a large radiation area, ensuring long service life. The multi-zone heating and temperature control guarantee excellent uniformity in the working temperature across different zones.

- Smart Insulation Design: The specially designed metal heat-insulation screen offers superior thermal insulation, resulting in significant energy savings.

- Advanced Multi-Zone Temperature Control: Employing sophisticated multi-zone temperature regulation ensures enhanced temperature uniformity within the furnace.

- Optimal Working Vacuum and Pressure Rise Rate: Achieving and maintaining high vacuum levels is crucial for quality brazing, and the furnace excels in this aspect.

Applications:

The Vacuum Brazing Furnace is primarily used for brazing stainless steel, carbon steel, copper, high-temperature alloys, titanium alloys, and aluminum heat exchangers. It is particularly effective with brazing filler metals such as nickel, copper, silver, and titanium. Applications extend to brazing components made of aluminum alloys, such as radar flat-panel antennas, and it can also facilitate the sintering of certain ceramic materials that require high vacuum and uniform temperature.

Advantages:

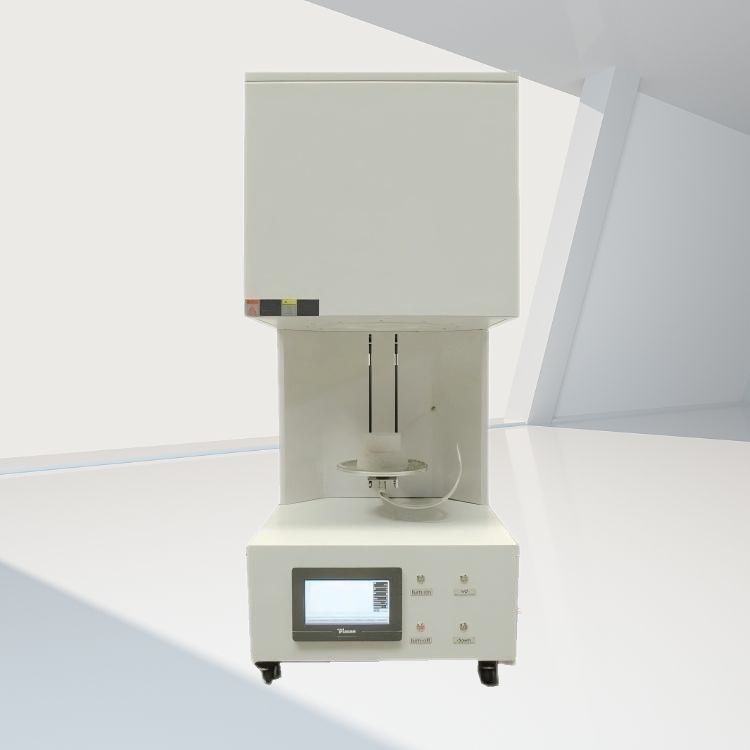

- High Automation: The furnace boasts high automation levels, featuring one-click functions for vacuum extraction and argon flushing processes. Continuous monitoring of water, power, and gas is automated, and users can observe operational status, alarm indicators, and temperature curves via a user-friendly touch screen interface.

- Premium Materials: Constructed entirely from 304 stainless steel and built according to pressure vessel standards, the furnace demonstrates exceptional corrosion resistance and sealing performance. High-temperature reflective insulation materials are used for durability, and all electrical components are sourced from reliable domestic and international brands for dependable operation.

- Enhanced Safety Features: The furnace incorporates automatic explosion-proof valves for safety assurance, along with a flow switch for real-time water flow monitoring. Electrical systems are meticulously configured to meet current and voltage overload requirements.

- Integrated Monitoring Interface: The furnace is equipped with a remote monitoring capability that allows managers to observe equipment status via a PC, retrieve operational records, and access process parameters whenever required.

The Vacuum Brazing Furnace offers unparalleled efficiency, safety, and versatility for high-quality brazing applications,it is an excellent choice for manufacturers seeking reliable and advanced soldering solutions.

Technical Parameter of the Vacuum Brazing Furnace:

Parameter of the 1600 degree Vacuum Brazing Furnace

| Work Size | m | 300*300*400 | 450*450*750 | 500*500*1200 | 500*500*1500 | 600*600*2000 | 750*750*2000 |

| Heat Method | / | Molybdenum/tungsten heater (Resistance heating) | |||||

| Loading Volume | L | 36 | 151 | 300 | 375 | 720 | 1125 |

| Loading Capacity | g | Customizable | |||||

| Power | KW | 55 | 85 | 160 | 185 | 225 | 300 |

| Ultra Vacuum | Pa | (cold state)6.67*10Pa(Customizable) | |||||

| Work Temperature | ℃ | 1550 | 1550 | 1550 | 1550 | 1550 | 1550 |

| Max.Temperature | ℃ | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 |

| Atmosphere | / | High Vacuum | |||||

Parameter of the 1300 degree Vacuum Brazing Furnace

| Work Size (mm) | Work.Temperature

(℃) |

Ultra Vacuum(Pa) | Pressure rise rate

(Pa/h) |

Power

(kw) |

| 200*200*300 | 1300 | 2*10-3 | ≤0.67 | 45 |

| 300*300*400 | 1300 | 2*10-3 | ≤0.67 | 60 |

| 400*400*600 | 1300 | 2*10-3 | ≤0.67 | 90 |

| 500*500*700 | 1300 | 2*10-3 | ≤0.67 | 120 |

| 600*600*900 | 1300 | 2*10-3 | ≤0.67 | 150 |

| 700*700*1200 | 1300 | 2*10-3 | ≤0.67 | 240 |

| 800*800*1500 | 1300 | 2*10-3 | ≤0.67 | 300 |

Q&A for Vacuum Brazing Furnace

- Q1: What is a Vacuum Brazing Furnace and how does it work?

- A1: A Vacuum Brazing Furnace is a specialized device designed for high-quality brazing of components in a vacuum chamber. It utilizes copper brazing wire, which heats and melts to create a strong, durable bond between various materials. By operating in a vacuum environment, the furnace minimizes oxidation and ensures the integrity of your workpieces during the welding process.

- Q2: What materials can be joined using the Vacuum Brazing Furnace?

- A2: Our Vacuum Brazing Furnace is versatile and capable of joining both similar and dissimilar materials. This feature expands the range of applications significantly, making it ideal for industries that require high-precision welding of various metals and alloys.

- Q3: How does the furnace ensure temperature uniformity during operation?

- A3: The design of our Vacuum Brazing Furnace includes rationally arranged heating elements, which provide a large radiation area and multi-zone heating capabilities. The advanced multi-zone temperature control system ensures a consistent and uniform working temperature throughout the furnace, essential for achieving optimal welding results.

- Q4: What energy-saving features does the Vacuum Brazing Furnace offer?

- A4: Our Vacuum Brazing Furnace incorporates a well-designed metallic thermal insulation screen, which effectively minimizes heat loss and optimizes thermal retention. This not only enhances operational efficiency but also significantly reduces energy consumption during the brazing process.

- Q5: What is the importance of maintaining a good vacuum and pressure rise rate in the furnace?

- A5: A good working vacuum and pressure rise rate are critical in the vacuum brazing process. They help in reducing contaminants and oxidation that could compromise the quality of the final weld. Our furnace is designed to maintain optimal vacuum conditions, ensuring a clean and controlled environment for your brazing operations.

- Q6: Is the Vacuum Brazing Furnace suitable for large-scale production?

- A6: Absolutely! The Vacuum Brazing Furnace is designed to handle both small and large-scale production runs. Its advanced features, coupled with a robust construction, make it an efficient solution for high-volume manufacturing environments that demand precision and reliability.

Feel free to reach out if you have any more questions or need further assistance regarding the Vacuum Brazing Furnace!Whether you are in research, analysis, or manufacturing, the vacuum brazing furnace supplied from SINOWIN INDUSTRY is your best choice.Donot hesitate to Contact us today for a quote and transform your scientific journey completely.

Technical Parameter of the Vacuum Brazing Furnace:

Parameter of the 1600 degree Vacuum Brazing Furnace

| Work Size | m | 300*300*400 | 450*450*750 | 500*500*1200 | 500*500*1500 | 600*600*2000 | 750*750*2000 |

| Heat Method | / | Molybdenum/tungsten heater (Resistance heating) | |||||

| Loading Volume | L | 36 | 151 | 300 | 375 | 720 | 1125 |

| Loading Capacity | g | Customizable | |||||

| Power | KW | 55 | 85 | 160 | 185 | 225 | 300 |

| Ultra Vacuum | Pa | (cold state)6.67*10Pa(Customizable) | |||||

| Work Temperature | ℃ | 1550 | 1550 | 1550 | 1550 | 1550 | 1550 |

| Max.Temperature | ℃ | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 |

| Atmosphere | / | High Vacuum | |||||

Parameter of the 1300 degree Vacuum Brazing Furnace

| Work Size (mm) | Work.Temperature

(℃) |

Ultra Vacuum(Pa) | Pressure rise rate

(Pa/h) |

Power

(kw) |

| 200*200*300 | 1300 | 2*10-3 | ≤0.67 | 45 |

| 300*300*400 | 1300 | 2*10-3 | ≤0.67 | 60 |

| 400*400*600 | 1300 | 2*10-3 | ≤0.67 | 90 |

| 500*500*700 | 1300 | 2*10-3 | ≤0.67 | 120 |

| 600*600*900 | 1300 | 2*10-3 | ≤0.67 | 150 |

| 700*700*1200 | 1300 | 2*10-3 | ≤0.67 | 240 |

| 800*800*1500 | 1300 | 2*10-3 | ≤0.67 | 300 |