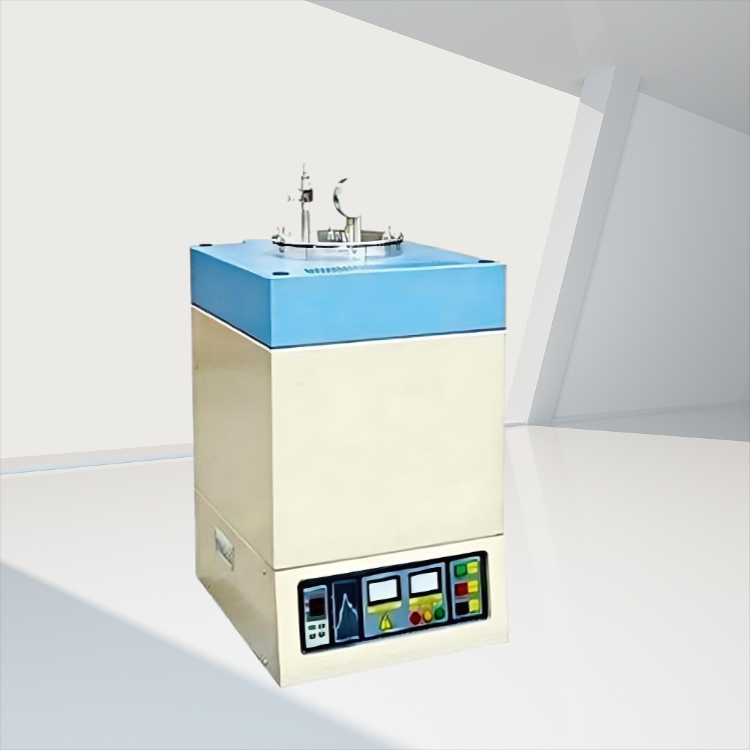

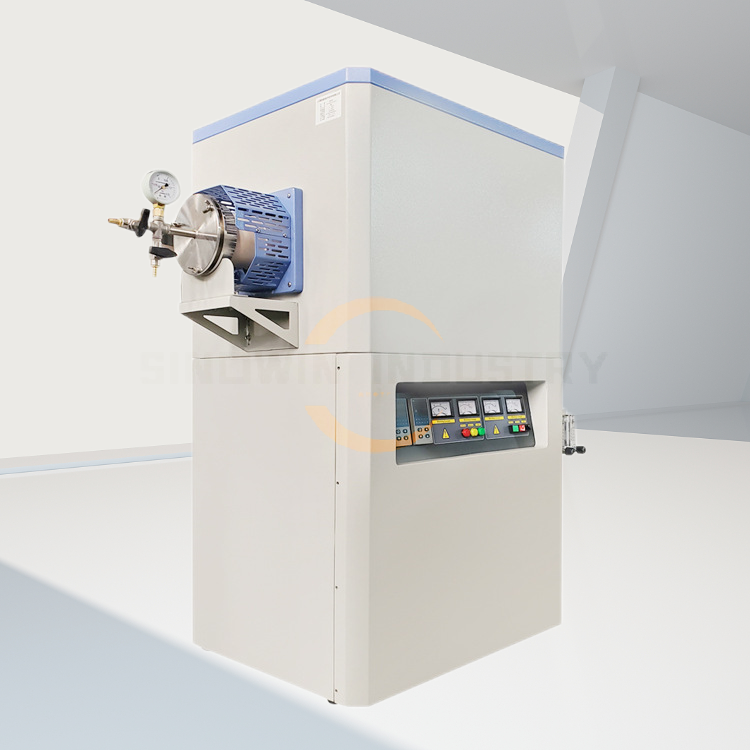

Product Description:

The Vacuum Deposition Furnace is a cutting-edge solution designed specifically for the preparation of carbon-carbon composite materials, facilitating the deposition of heat-treated carbon coatings on graphite, semiconductor devices, and high-temperature erosion-resistant materials. This advanced equipment is essential for various applications in research and industrial settings, ensuring optimal performance and superior surface refinement.

Application Range:

- Graphite

- Semiconductor Devices

- High-Temperature Erosion-Resistant Materials

Key Specifications:

- Design Temperatures: 1250℃ / 1650℃ / 1800℃ / 2200℃

- Operating Temperature Range: 900~1200℃

- Vacuum Level: < 50 Pa

- Pressure Rise Rate: Empty furnace cold state at 6.67 Pa/h or 150 Pa/24h

- Heating Method: Graphite resistance heating or induction heating with independent temperature control for excellent temperature uniformity

- Atmospheric Media: Vacuum / CH4 / C3H6 / H2 / N2 / Ar

- Gas Control Method: Mass flow controller with multi-channel gas routing, ensuring a uniform flow field without deposition dead spots for superior deposition results

- Efficient Exhaust Treatment System: Multi-stage, environmentally friendly design that is easy to clean

- Furnace Design Options: Square, circular, vertical or horizontal structures (custom design available), featuring a fully enclosed deposition chamber with strong sealing ability and high contamination resistance

- Cooling Method for Furnace Body: Water-cooled shell with optional external rapid cooling system for reduced cooling time and increased production efficiency

Furnace Structure:

- Design Form: Horizontal with side discharge, Vertical with top/bottom discharge

- Door Locking Method: Manual or automatic

- Furnace Shell Material: Inner layer stainless steel / fully stainless steel

- Insulation Material: Carbon felt / graphite felt / carbon fiber cured felt

- Heater and Muffler Material: Graphite / CFC

- Infrared Meter: Single colorimetric / dual colorimetric

- Power Supply: KGPS / IGBT (suitable for medium frequency heating only)

The Vacuum Deposition Furnace is engineered with precision and embodies advanced technology to meet the exacting standards of modern manufacturing and research demands. Trust in the reliability and efficiency of our system for your critical applications in the fields of material science and engineering.

Whether you are in research, analysis, or manufacturing, the Vacuum Deposition Furnace supplied from SINOWIN INDUSTRY is your best choice.

Donot hesitate to Contact us today for a quote and transform your scientific journey completely.

Technical Parameter of the High-Performance Vacuum Deposition Furnace:

| Work size XH(mm) | 300X500 | 500×500 | 600X800 | 600X1200 | 800X1200 | 1100X2000 | 1200X1800 | 1500×2000 |

| Max.Temp.

(℃) |

2300 | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 |

| Temp.uniformity

(℃) |

±5 | ±5 | ±5/±7.5 | ±7.5/±10 | ±7.5/±10 | ±10/±15 | ±10/±15 | ±15/±20 |

| Ultra Vacuum

(Pa) |

1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 |

| Pressure rise rate(Pa/h) | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 |

| Heat Method | Resistance Heating/IGBT Heating | |||||||

Q&As for the Vacuum Deposition Furnace:

**Q1: What temperature options are available for the Vacuum Deposition Furnace?**

A1: Our Vacuum Deposition Furnace is designed to accommodate high temperatures of 1250℃, 1650℃, 1800℃, and up to 2200℃. The common operating temperature range is between 900℃ and 1200℃, making it versatile for various applications.

**Q2: What is the vacuum level that this furnace can achieve?**

A2: The vacuum deposition furnace can achieve an impressive vacuum level of less than 50Pa, ensuring optimal conditions for deposition processes and enhancing the quality of your outputs.

**Q3: How does the furnace maintain temperature uniformity during operations?**

A3: The furnace features an advanced heating system utilizing either graphite resistance heating or induction heating. This system is equipped with independent temperature control, which provides excellent temperature uniformity throughout the entire chamber for consistent results.

**Q4: What types of gases can be used within the furnace?**

A4: You can use various atmospheres within the furnace, including vacuum, CH4, C3H6, H2, N2, and Argon (Ar). This flexibility allows for a wide range of deposition processes tailored to your specific needs.

**Q5: How is the gas flow controlled in the vacuum chamber?**

A5: Our furnace utilizes mass flow controllers to monitor and control gas flow meticulously. The multi-channel gas circuit ensures a uniform flow field, eliminating deposition dead zones and significantly enhancing the deposition effectiveness.

**Q6: Is there an exhaust treatment system in place?**

A6: Yes, the furnace is equipped with a multi-stage high-efficiency exhaust treatment system that is environmentally friendly and easy to clean, helping you maintain a safe working environment while adhering to regulatory standards.

**Q7: What are the available designs for the furnace’s structure?**

A7: The Vacuum Deposition Furnace comes in various configurations, including square, round, vertical, or horizontal structures. Additionally, we offer custom designs that include a fully sealed deposition chamber for superior sealing performance and enhanced contamination resistance.

**Q8: Why should I choose this Vacuum Deposition Furnace over others?**

A8: Our Vacuum Deposition Furnace stands out for its high-temperature capacity, excellent vacuum levels, superior temperature uniformity, flexible gas atmosphere options, and effective exhaust treatment systems. This combination not only guarantees outstanding deposition quality but also ensures a safe and efficient operational process, meeting the high standards of your manufacturing needs.

Technical Parameter of the High-Performance Vacuum Deposition Furnace:

| Work size XH(mm) | 300X500 | 500×500 | 600X800 | 600X1200 | 800X1200 | 1100X2000 | 1200X1800 | 1500×2000 |

| Max.Temp.

(℃) |

2300 | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 |

| Temp.uniformity

(℃) |

±5 | ±5 | ±5/±7.5 | ±7.5/±10 | ±7.5/±10 | ±10/±15 | ±10/±15 | ±15/±20 |

| Ultra Vacuum

(Pa) |

1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 |

| Pressure rise rate(Pa/h) | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 |

| Heat Method | Resistance Heating/IGBT Heating | |||||||