Product Description:

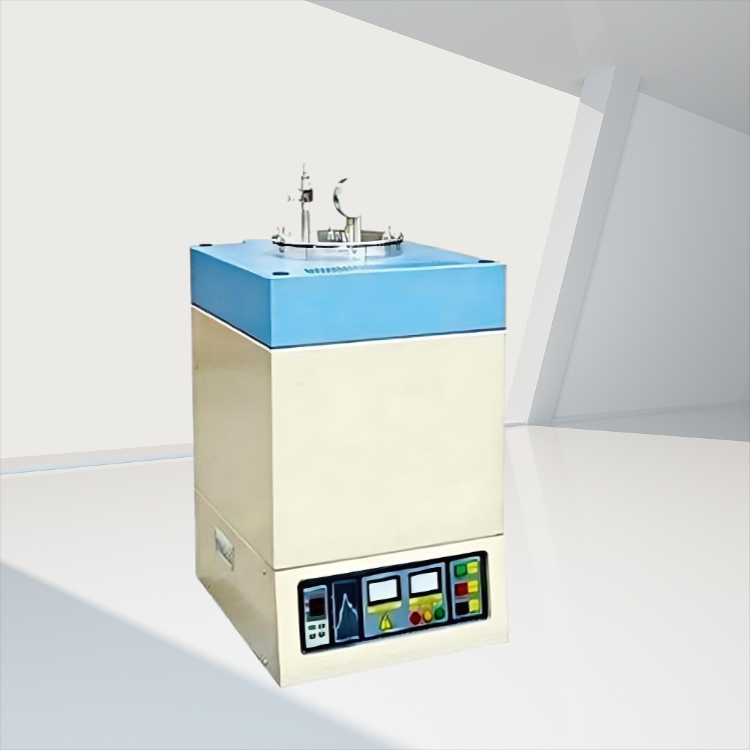

The Vacuum Hot Press Furnace, a comprehensive system designed for the thermal pressing and shaping of materials under vacuum or other atmospheric conditions, employs a graphite heating method and features a hydraulically driven press head, ensuring efficient and effective processing.

During operation, at elevated temperatures, the vacuum hot press furnace facilitates the bonding of solid particles, grain growth, and the gradual reduction of pores and grain boundaries. Through material transfer, the overall volume shrinks while density increases, ultimately yielding a dense polycrystalline sintered body with specific microstructural characteristics. The simultaneous application of high temperature, pressure, and controlled atmospheres significantly enhances the density, hardness, and various mechanical, electronic, and thermal properties of the final products.Whether you are in research, analysis, or manufacturing, the Vacuum Hot Press Furnace supplied from SINOWIN INDUSTRY is your best choice.

Donot hesitate to Contact us today for a quote and transform your scientific journey completely.

Key Applications:

- Hot pressing and sintering of metal and ceramic powders.

- Preparation of ceramic/metal composite materials and intermetallic compounds.

- Research and development in diffusion welding technologies.

- Densification of oxides, nitrides, borides, carbides, and their mixtures through hot pressing.

Product Features:

- Dual-layer SUS304 Furnace Body: Engineered for optimal thermal management, the dual-layer structure includes a central cooling water passage, effectively reducing surface temperature to minimize high-temperature risks and environmental impact.

- Robust Frame Construction: Utilizing a four-column support structure and robust profile welding, the furnace ensures superior reliability and stability during operation.

- Advanced Insulation Materials: With a low thermal conductivity, the advanced insulation and heat-separation design guarantee exceptional thermal retention and energy efficiency, even at high operational temperatures.

- Wide Temperature Range: The furnace offers multiple heating element options, including graphite, molybdenum, tungsten, and induction heating, capable of achieving temperatures up to 3000°C in suitable protective atmospheres, accommodating various materials for hot pressing and sintering.

- Versatile Vacuum Systems: Configurable vacuum systems allow for the selection of different vacuum levels based on specific process requirements.

- Gas Charging and Discharging System: Flexibility to conduct hot pressing and sintering in vacuum, inert, or reducing atmospheres enhances operational versatility.

- User-friendly Operation: Designed for both manual and intelligent operation, facilitating ease of use and adaptability to different user preferences.

- Multi-functional Utility: The equipment can serve as a dedicated vacuum furnace or operate in various atmospheric conditions.

- Diverse Configurations: Choose from a variety of discharge styles—vertical upward discharge, vertical side discharge, unidirectional or bidirectional pressure—allowing for customization based on operational needs.

The Vacuum Hot Press Furnace that supplied by sinowin industry is the ideal tool for advancing the field of materials processing, providing exceptional capabilities for producing high-density materials through innovative thermal and pressure applications. Whether you are conducting in-depth research or scaling up production, our furnace promises to meet and exceed your expectations in efficiency and performance.

Technical Parameter of the 800-3000°C Vacuum Hot Press Furnace:

| work zone | Work Temp. | Ultra Vacuum | Power | Pressure | Remarks |

| Ф200×200 | 1000℃ | 6.67×10-3pa | 60KW | 20T | Molybdenum wire heating |

| Ф150×200 | 1600℃ | 6.67×10-3pa | 50KW | 20T | single phase |

| Ф90×120 | 2000℃ | 6.67×10-3pa | 25KW | 10T | single phase |

| Ф160×160 | 2000℃ | 6.67×10-3pa | 40KW | 20T | single phase |

| Ф250×250 | 2000℃ | 6.67×10-3pa | 120KW | 30T | three phase |

| Ф150×180 | 2200℃ | 6.67×10-3pa | 120KW | 10T | three phase |

| Ф300×300 | 2600℃ | 10pa | 120KW | 100T | IGBT HEATING |

| Ф420×400 | 2200℃ | 6.67×10-3pa | 120KW | 120T | Resistance heating |

| Ф600×450 | 2600℃ | 5pa | 150KW | 350T | IGBT HEATING |

Please feel free to consult for any additional questions or specifics related to your requirements for our vacuum hot press furnace!and Nanyang sinowin industry co.ltd are not only a lab and industrial furnace supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Product Q&As for your vacuum hot press furnace:

Q1: What is a vacuum hot press furnace used for?

A1: A vacuum hot press furnace is primarily used for the densification and consolidation of materials under heat and vacuum. It is ideal for processing ceramics, composites, metals, and polymers, resulting in products with superior density and mechanical properties. This makes it a critical tool in industries such as aerospace, automotive, and electronics.

Q2: How does a vacuum hot press furnace improve product quality?

A2: The vacuum environment in a hot press furnace minimizes oxidation and contamination, allowing for a uniform heat distribution and creating a homogenous product. This leads to enhanced material properties such as increased strength, durability, and thermal stability, ultimately producing high-quality end products with fewer defects.

Q3: What types of materials can be processed using a vacuum hot press furnace?

A3: A vacuum hot press furnace can handle a wide range of materials including ceramics, composite materials, metal alloys, and thermoplastic and thermosetting polymers. This versatility makes it suitable for various applications across multiple industries.

Q4: What are the advantages of using a vacuum hot press furnace?

A4: The advantages of using a vacuum hot press furnace include improved product quality, reduced porosity, greater control over the heating and cooling rates, and the ability to produce complex shapes. Additionally, the vacuum environment reduces the risk of oxidation, ensuring cleaner processing that can enhance the performance of the final product.

Q5: How do I choose the right vacuum hot press furnace for my application?

A5: To choose the right vacuum hot press furnace, consider the following factors: the type of materials you will be processing, the desired temperature and pressure conditions, the size and shape of the components, and production volume requirements. It is also beneficial to consult with manufacturers who can provide specific recommendations based on your needs.

Q6: What is the difference between vacuum hot pressing and traditional pressing?

A6: The key difference lies in the environment in which the process occurs. Vacuum hot pressing takes place under a vacuum, which prevents oxidation and contamination, whereas traditional pressing occurs in ambient conditions, which may lead to reduced material quality. Additionally, vacuum hot pressing offers superior control over temperature and pressure, resulting in better density and mechanical properties.

Q7: How should I maintain a vacuum hot press furnace?

A7: Regular maintenance of a vacuum hot press furnace involves checking the vacuum integrity, cleaning the heating elements, inspecting seals and gaskets for wear and tear, and ensuring all controls and automation systems are functioning correctly. Regularly scheduled maintenance checks by professionals can help prolong the life and efficiency of the furnace.

Q8: Are there safety hazards associated with using a vacuum hot press furnace?

A8: While vacuum hot press furnaces are generally safe to operate, potential hazards include high temperatures, pressurized environments, and electrical components. It is crucial to follow the manufacturer’s safety guidelines, utilize protective equipment, and implement proper training for operators to minimize risks.

Q9: What is the typical lifespan of a vacuum hot press furnace?

A9: The typical lifespan of a vacuum hot press furnace can range from 10 to 20 years, depending on factors such as usage frequency, maintenance routine, and operating conditions. Regular maintenance and care can significantly extend the lifespan of the equipment, ensuring continued performance and reliability.

Q10: Can vacuum hot pressing be used for polymer materials?

A10: Yes, vacuum hot pressing is highly effective for polymer materials, including thermoplastics and thermosetting polymers. The process enhances polymer consolidation, reduces voids, and improves overall material properties, making it an excellent choice for applications in various industries, such as electronics and automotive.

Technical Parameter of the 800-3000°C Vacuum Hot Press Furnace:

| work zone | Work Temp. | Ultra Vacuum | Power | Pressure | Remarks |

| Ф200×200 | 1000℃ | 6.67×10-3pa | 60KW | 20T | Molybdenum wire heating |

| Ф150×200 | 1600℃ | 6.67×10-3pa | 50KW | 20T | single phase |

| Ф90×120 | 2000℃ | 6.67×10-3pa | 25KW | 10T | single phase |

| Ф160×160 | 2000℃ | 6.67×10-3pa | 40KW | 20T | single phase |

| Ф250×250 | 2000℃ | 6.67×10-3pa | 120KW | 30T | three phase |

| Ф150×180 | 2200℃ | 6.67×10-3pa | 120KW | 10T | three phase |

| Ф300×300 | 2600℃ | 10pa | 120KW | 100T | IGBT HEATING |

| Ф420×400 | 2200℃ | 6.67×10-3pa | 120KW | 120T | Resistance heating |

| Ф600×450 | 2600℃ | 5pa | 150KW | 350T | IGBT HEATING |