Product Description:

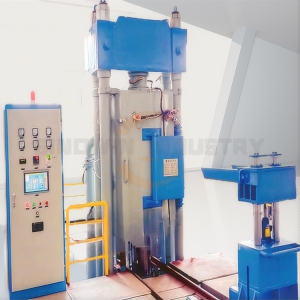

The Vacuum Hot Press Sintering Furnace is used for the advanced manufacturing of various composite materials and high thermal conductivity substances. This exceptional furnace produced by nanyang sinowin industry excels in processing materials such as SiC, Si3N4, B4C ceramics, copper-based powders, iron-based powders, and iron-copper-based powders. With a maximum sintering temperature reaching up to 2800℃, it’s perfect for applications in high-performance areas, including aircraft landing gear brake discs, high-speed train brake pads, ballistic vests, armored vehicle shields, and helicopter armored helmets.

Key features include:

- Temperature Versatility: Operating temperatures can be customized from 1500℃ to 2500℃, allowing for flexibility in processing various materials.

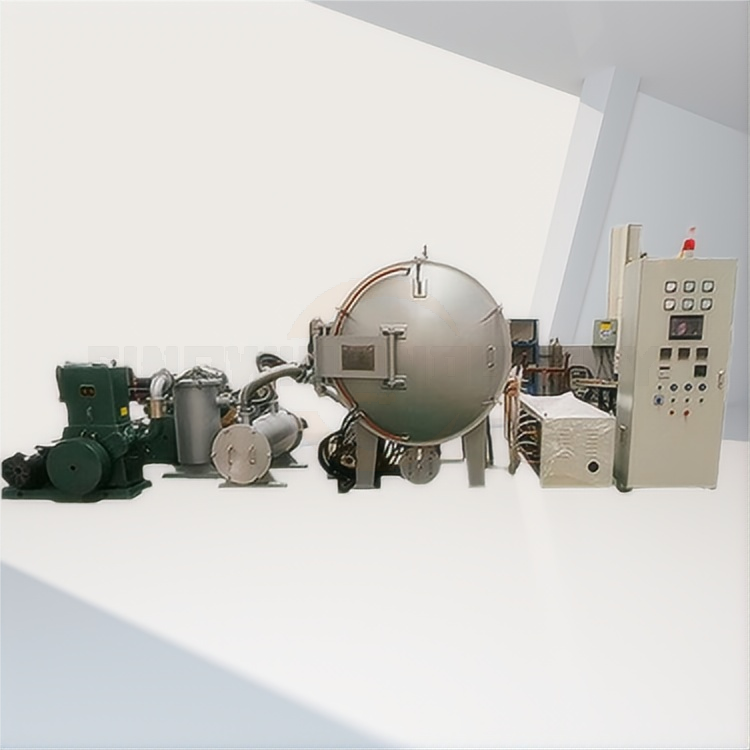

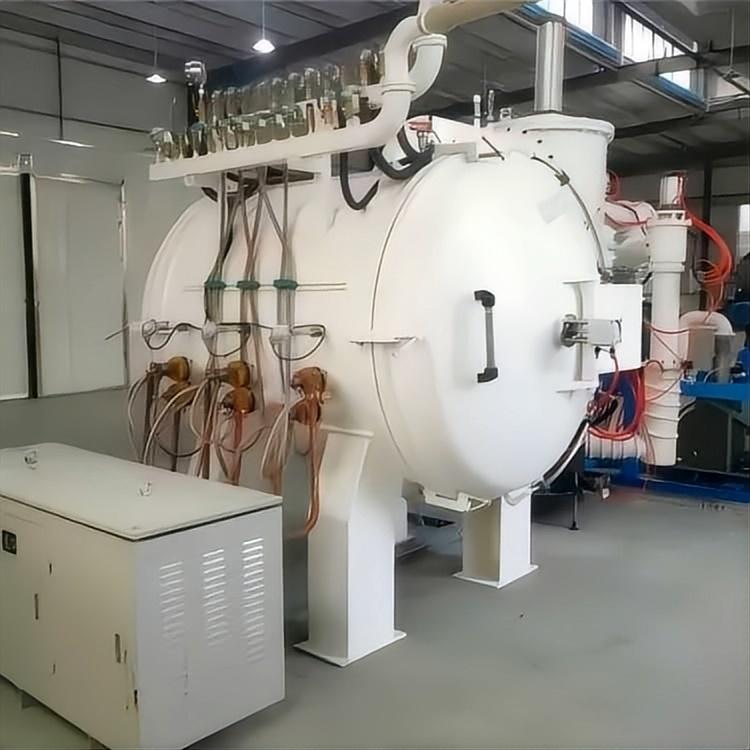

- Operational Integrity: The furnace can function under vacuum conditions or in a “positive pressure” atmosphere, accommodating H2 and Ar environments, which significantly enhances the quality of pressing for materials like CuZnSn powders.

- Robust Construction: The dual-layer SUS304 furnace body structure, equipped with water cooling channels, effectively reduces surface temperatures to minimize the risk of high-temperature damage and environmental impact.

- Secure Support Design: The framework features a dual-column support structure constructed from welded profiles, ensuring high reliability and stability of the equipment.

- Excellent Insulation: Advanced insulation materials and heat-shielding designs deliver low thermal conductivity, effectively preserving energy even at elevated temperatures.

- Heating Element Diversity: Multiple heating elements such as graphite, molybdenum, tungsten, and tantalum are available, creating the potential for temperature adaptations up to 2400℃ in optimal protective atmospheres.

- Customized Vacuum System: Tailor your process with a variety of vacuum level options, ensuring that the furnace suits different operational requirements.

- Flexible Exhaust System: Designed for versatility, the furnace operates efficiently in either vacuum or inert/reducing atmospheres.

- Intuitive Operation: Our user-friendly configuration allows for both manual operation and one-touch smart functionality.

- Versatile Applications: The furnace can serve as a standard vacuum or atmosphere sintering furnace, with various options for feed direction and pressure application.

- Customizable Solutions: We offer non-standard customizations to meet your specific processing needs.

- The Vacuum Hot Press Sintering Furnace is your ultimate solution for high-precision, energy-efficient sintering of advanced materials. With unparalleled performance in demanding applications, this furnace stands poised to elevate your manufacturing capabilities.

Parameter of the 2400 degree Vacuum Hot Press Sintering Furnace with round chamber :

| Work size

D*H mm |

Max.work terperature | Ultra Vacuum (cooling status)Pa | Pressure rate Pa/h | Power Kw | Pressure (T) |

| Φ150*200 | 2400 | 5*10 | 3 | 50 | 20-200 |

| Φ200*300 | 2400 | 5*10 | 5 | 75 | 20-200 |

| Φ300*400 | 2400 | 5*10 | 6 | 100 | 20-200 |

| Φ400*500 | 2400 | 5*10 | 6 | 200 | 20-300 |

| Φ500*600 | 2400 | 5*10 | 6.5 | 300 | 20-400 |

| Φ600*700 | 2400 | 5*10 | 6.5 | 400 | 20-400 |

Parameter of the 2400 degree Vacuum Hot Press Sintering Furnace with square chamber:

| WorK Size -W×H×L(mm) | 400×400×600 | 500×500×600 | 600×600×600 | 700×700×700 |

| Heating power(kW) | 200 | 245 | 290 | 325 |

| Max.work Temperature(℃) | 2400 | 2400 | 2400 | 24000 |

| Pressure tonnage(T) | 30-200 | 50-300 | 100-400 | 150-500 |

| Temperature uniformity(℃) | ±5 | ±5 | ±5 | ±5 |

| Vacuum(Pa) | 5/4×10-3/6×10-4 | 5/4×10-3/6×10-4 | 5/4×10-3/6×10-4 | 5/4×10-3/6×10-4 |

| Rate of the pressure rise(Pa/h) | ≤0.26 | ≤0.26 | ≤0.26 | ≤0.26 |

| ≤0.65 | ≤0.65 | ≤0.65 | ≤0.65 |

Advantage of our Vacuum Hot Press Sintering Furnace:

- High-Temperature Capability: The Vacuum Hot Press Sintering Furnace reaches maximum sintering temperatures of up to 2800℃, making it ideal for the fabrication of advanced materials such as high thermal conductivity composites and ceramic components like SiC, Si3N4, and B4C.

- Versatile Applications: This innovative furnace is perfectly suited for producing components including aircraft brake discs, high-speed train brake pads, ballistic armor, and vehicle protection plates, catering to a wide range of industrial needs.

- Robust and Reliable Design: Featuring a dual-layer SUS304 furnace body with water cooling, and a frame-style dual-column support structure, this furnace ensures reliability and reduces surface temperature to protect against high thermal effects.

- Energy Efficient Operation: The Vacuum Hot Press Sintering Furnace utilizes high-quality insulating materials and structures that minimize thermal conductivity, maintaining efficient energy consumption even at elevated temperatures.

- Customizable and User-Friendly: With options for manual or one-button intelligent operation, various heating elements, and customizable configurations including gas atmosphere settings, this furnace offers exceptional flexibility to meet diverse processing requirements.

Q1: What materials can be processed in the Vacuum Hot Press Sintering Furnace?

A: Our Vacuum Hot Press Sintering Furnace is designed to handle a diverse range of materials. It is particularly suitable for composite materials, high thermal conductivity materials, and various ceramic materials such as SiC, Si3N4, and B4C. This furnace is also effective for copper-based and iron-based powder materials, making it ideal for producing parts like brake discs for aircraft, brake pads for high-speed trains, bulletproof vests, armored vehicle plates, and helicopter armor.

Q2: What is the maximum sintering temperature that this furnace can achieve?

A: The Vacuum Hot Press Sintering Furnace operates at a maximum sintering temperature of 2800°C. This high temperature capability ensures effective densification and near-net-shape manufacturing for a wide variety of high-performance materials.

Q3: Can the furnace operate under different atmospheric conditions?

A: Yes, our furnace is versatile and can operate under a vacuum condition as well as in positive pressure atmospheres such as hydrogen (H2) and argon (Ar). This flexibility allows for improved quality in the forming process of various powder materials, particularly those in the CuZnSn category.

Q4: What are the available temperature settings for this furnace?

A: The Vacuum Hot Press Sintering Furnace offers adjustable temperature settings, allowing users to select from 1500°C, 1800°C, 2000°C, 2300°C, 2400°C, and 2500°C. This range accommodates a variety of sintering requirements depending on the material and application.

Q5: How long can the pressure be maintained during the sintering process?

A: In the 2400°C high-temperature setting, the pressure can be maintained consistently for up to 12 hours. This capability ensures high precision in pressure retention, critical for achieving optimal densification and material properties.

Q6: What type of insulation does the furnace utilize?

A: The furnace is equipped with a graphite insulation screen, which provides excellent thermal insulation, ensuring efficient heat management during the sintering process. This feature contributes to reduced energy consumption and improved performance.

Q7: Is this furnace suitable for high-precision applications?

A: Absolutely. The design and capabilities of our Vacuum Hot Press Sintering Furnace make it highly suitable for high-precision applications. With its ability to maintain exact temperature and pressure settings, it is ideal for producing components that require tight tolerances and exceptional material properties.

Whether you are in research, analysis, or manufacturing, the Vacuum Hot Press Sintering Furnace supplied from SINOWIN INDUSTRY is one guaranteed option for your heating treatment industry.

Donot hesitate to Contact us at once for quotation of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Parameter of the 2400 degree Vacuum Hot Press Sintering Furnace with round chamber :

| Work size

D*H mm |

Max.work terperature | Ultra Vacuum (cooling status)Pa | Pressure rate Pa/h | Power Kw | Pressure (T) |

| Φ150*200 | 2400 | 5*10 | 3 | 50 | 20-200 |

| Φ200*300 | 2400 | 5*10 | 5 | 75 | 20-200 |

| Φ300*400 | 2400 | 5*10 | 6 | 100 | 20-200 |

| Φ400*500 | 2400 | 5*10 | 6 | 200 | 20-300 |

| Φ500*600 | 2400 | 5*10 | 6.5 | 300 | 20-400 |

| Φ600*700 | 2400 | 5*10 | 6.5 | 400 | 20-400 |

Parameter of the 2400 degree Vacuum Hot Press Sintering Furnace with square chamber:

| WorK Size -W×H×L(mm) | 400×400×600 | 500×500×600 | 600×600×600 | 700×700×700 |

| Heating power(kW) | 200 | 245 | 290 | 325 |

| Max.work Temperature(℃) | 2400 | 2400 | 2400 | 24000 |

| Pressure tonnage(T) | 30-200 | 50-300 | 100-400 | 150-500 |

| Temperature uniformity(℃) | ±5 | ±5 | ±5 | ±5 |

| Vacuum(Pa) | 5/4×10-3/6×10-4 | 5/4×10-3/6×10-4 | 5/4×10-3/6×10-4 | 5/4×10-3/6×10-4 |

| Rate of the pressure rise(Pa/h) | ≤0.26 | ≤0.26 | ≤0.26 | ≤0.26 |

| ≤0.65 | ≤0.65 | ≤0.65 | ≤0.65 |