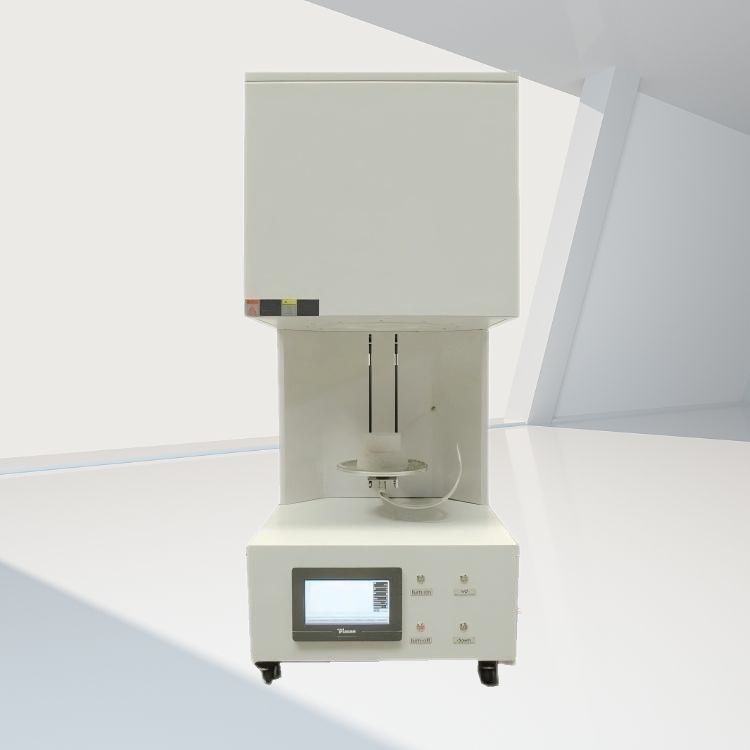

Product Description:

The Vacuum Sintering Furnace, expertly designed for a variety of applications including powder metallurgy, metallic materials, ceramic materials, magnetic materials, and hard alloys. This versatile furnace is capable of accommodating sintering processes, as well as brazing, annealing, and tempering, making it an essential tool for any advanced materials laboratory.

Product Features:

- Heating Options: The Vacuum Sintering Furnace offers flexible heating methods, utilizing high-quality metal tungsten, molybdenum, or graphite for resistance heating, or induction heating for enhanced efficiency.

- Temperature Range: With maximum temperature options of 1300℃, 1600℃, 1800℃, 2200℃, and 2400℃, this furnace can be tailored to meet the specific needs of your sintering processes.

- Material Discharge Mechanism: Customize your furnace with either upper or lower material discharge configurations to suit your workflow requirements.

- Vacuum Configuration: Choose between medium vacuum and high vacuum settings to optimize your sintering atmosphere, suitable for nitrogen, inert gases, and other controlled environments.

- Rapid Cooling System: Enhance your processing capabilities with the option to configure a rapid cooling system, ensuring optimal results in a fraction of the time.

- Custom Dimensions: We understand that every application is unique. Therefore, our Vacuum Sintering Furnace can be customized according to your specified dimensions to perfectly fit your production line.

To elevate your sintering processes with Sinowin Industry’s highly capable Vacuum Sintering Furnace—a reliable solution for achieving exceptional material characteristics. Whether you are in R&D or large-scale manufacturing, this furnace is engineered to deliver outstanding performance and flexibility for all your sintering and heat treatment needs.

Technical Parameter

Parameter of 1600°C Vacuum Sintering Furnace

| Model | Working Size

(mm) |

Max(℃) | Ultimate Vacuum(Pa) | Temperature uniformity(℃) | Pressure rise rate(Pa/h) | Heating power (kw) |

| SVSL112 | 120*120*200 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 30 |

| SVSL223 | 200*200*300 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 40 |

| SVSL334 | 300*300*400 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 60 |

| SVSL446 | 400*400*600 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 80 |

| SVSL557 | 500*500*700 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 90 |

| SVSL669 | 600*600*900 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 150 |

| SVSL7712 | 700*700*1200 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 240 |

Parameter of 2200°C Vacuum Sintering Furnace

| Working temperature(℃) | 2200 | 2200 | 2000 | 2000 |

| Ultimate temperature(℃) | 2300 | 2300 | 2100 | 2100 |

| Working size(mm) | Φ600X1500 | Φ1000X1600 | Φ1300X1800 | Φ1800X2000 |

| Power(KW) | 250 | 400 | 500 | 800 |

| Heating Method | Resistance Heating | |||

| Atmosphere | High Vacuum/ Vacuum(optional)N²、Ar | |||

| Ultimate Vacuum (Pa) | 6.6X10ˉ3 | |||

Parameter of 2400°C Vacuum Sintering Furnace

| Model | SVSL4412

|

SVSL5514

|

SVSL5516

|

SVSL8830

|

| Working temperature(℃) | 2400 | 2400 | 2400 | 2400 |

| Ultimate temperature(℃) | 2500 | 2500 | 2500 | 2500 |

| Working size(mm) | 400X400X1200 | 500X500X1400 | 550X550X1600 | 800X800X3000 |

| Power(KW) | 150 | 250 | 350 | 800 |

| Heating Method | IGBT | |||

| Atmosphere | High Vacuum/Vacuum (optional )N²、Ar etc. | |||

| Ultimate Vacuum (pa) | 6.6X10ˉ3 | |||

Whether you are in research, analysis, or manufacturing, the Vacuum Sintering Furnace supplied from SINOWIN INDUSTRY is one guaranteed option for your heating treatment industry.

Donot hesitate to Contact us at once for quotation of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the heat treatment .

Q&A for Vacuum Sintering Furnace

Q1: What is a vacuum sintering furnace?

A1: A vacuum sintering furnace is a specialized industrial oven designed to heat materials in a vacuum environment, significantly reducing oxidation and contamination. It is primarily used in the manufacturing of advanced ceramics, metal parts, and composite materials, where precise temperature control and a clean atmosphere are crucial for achieving the desired material properties. By eliminating air, this furnace facilitates the densification process, enhancing the mechanical strength and durability of the end product.

Q2: How does a vacuum sintering furnace work?

A2: The vacuum sintering furnace operates by first creating a vacuum inside the chamber to remove any atmospheric gasses. Once the desired vacuum level is reached, the furnace gradually heats the material to its sintering temperature, which allows particles to bond at a molecular level. This process not only improves the density and strength of the material but also prevents unwanted reactions that can occur in the presence of air. Continuous monitoring and control systems ensure optimal conditions throughout the sintering process.

Q3: What materials can be processed in a vacuum sintering furnace?

A3: A vacuum sintering furnace is versatile and can process a wide range of materials, including advanced ceramics like alumina and zirconia, metals such as titanium and tungsten, as well as metal ceramic composites. This capability makes it ideal for industries such as aerospace, automotive, electronics, and biomedical, where superior material properties are required for high-performance applications.

Q4: What are the benefits of using a vacuum sintering furnace in manufacturing?

A4: Utilizing a vacuum sintering furnace offers numerous benefits, including enhanced material purity due to the absence of contaminants, superior mechanical properties through efficient densification, and the ability to process complex geometries that might otherwise be challenging. Additionally, it allows for better control over the sintering atmosphere, leading to improved consistency and reliability of the final products.

Q5: Can I use a vacuum sintering furnace for small-scale production?

A5: Absolutely! Vacuum sintering furnaces come in various sizes, including compact models suitable for small-scale production or research purposes. Whether you’re working on prototyping new materials or producing limited runs of high-quality components, you can achieve professional-grade results with a vacuum sintering furnace tailored to your operational needs.

Q6: Is it easy to operate a vacuum sintering furnace?

A6: Yes, modern vacuum sintering furnaces are designed with user-friendly interfaces and advanced control systems that simplify the operation process. Most models come equipped with digital displays, programmable settings, and safety features to ensure optimal performance. While some basic training may be recommended, operators can quickly learn to set up and monitor the sintering process effectively.

Any questions about our Vacuum Sintering Furnace,please feel free to consult for more available information .

Parameter of 1600°C Vacuum Sintering Furnace

| Model | Working Size

(mm) |

Max(℃) | Ultimate Vacuum(Pa) | Temperature uniformity(℃) | Pressure rise rate(Pa/h) | Heating power (kw) |

| SVSL112 | 120*120*200 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 30 |

| SVSL223 | 200*200*300 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 40 |

| SVSL334 | 300*300*400 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 60 |

| SVSL446 | 400*400*600 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 80 |

| SVSL557 | 500*500*700 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 90 |

| SVSL669 | 600*600*900 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 150 |

| SVSL7712 | 700*700*1200 | 1600 | 6.6*10-3 | ±3 | ≤0.67 | 240 |

Parameter of 2200°C Vacuum Sintering Furnace

| Working temperature(℃) | 2200 | 2200 | 2000 | 2000 |

| Ultimate temperature(℃) | 2300 | 2300 | 2100 | 2100 |

| Working size(mm) | Φ600X1500 | Φ1000X1600 | Φ1300X1800 | Φ1800X2000 |

| Power(KW) | 250 | 400 | 500 | 800 |

| Heating Method | Resistance Heating | |||

| Atmosphere | High Vacuum/ Vacuum(optional)N²、Ar | |||

| Ultimate Vacuum (Pa) | 6.6X10ˉ3 | |||

Parameter of 2400°C Vacuum Sintering Furnace

| Model | SVSL4412

|

SVSL5514

|

SVSL5516

|

SVSL8830

|

| Working temperature(℃) | 2400 | 2400 | 2400 | 2400 |

| Ultimate temperature(℃) | 2500 | 2500 | 2500 | 2500 |

| Working size(mm) | 400X400X1200 | 500X500X1400 | 550X550X1600 | 800X800X3000 |

| Power(KW) | 150 | 250 | 350 | 800 |

| Heating Method | IGBT | |||

| Atmosphere | High Vacuum/Vacuum (optional )N²、Ar etc. | |||

| Ultimate Vacuum (pa) | 6.6X10ˉ3 | |||