Product Description:

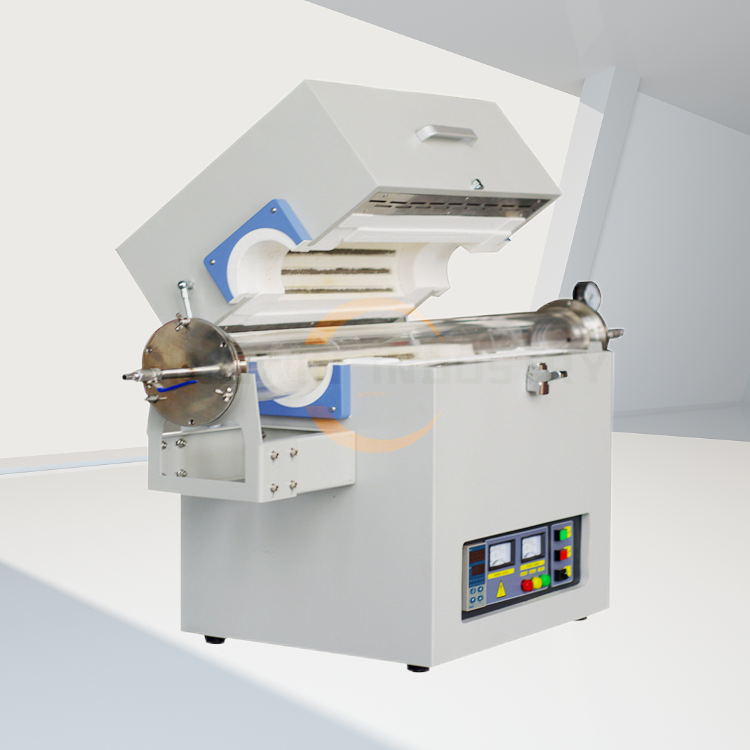

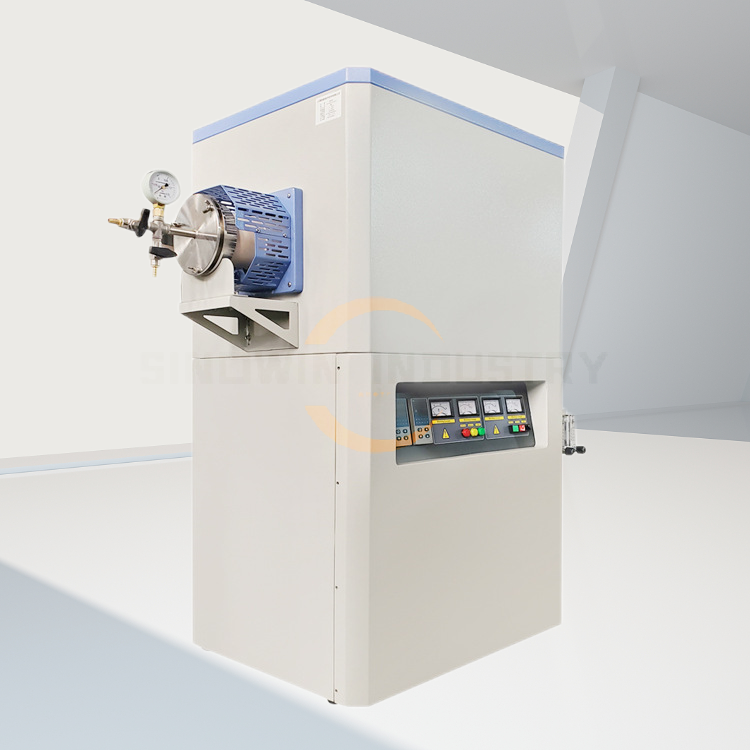

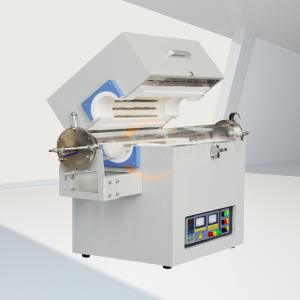

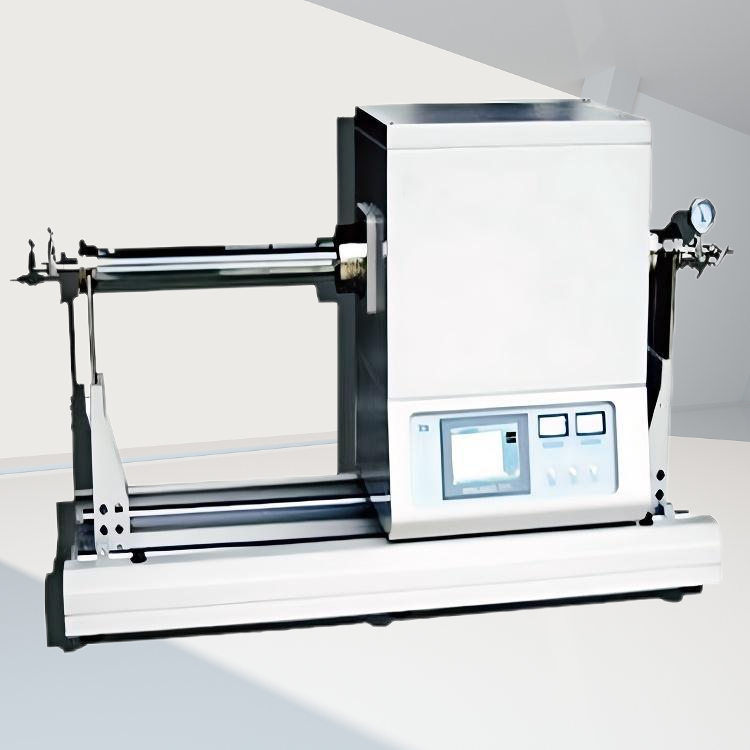

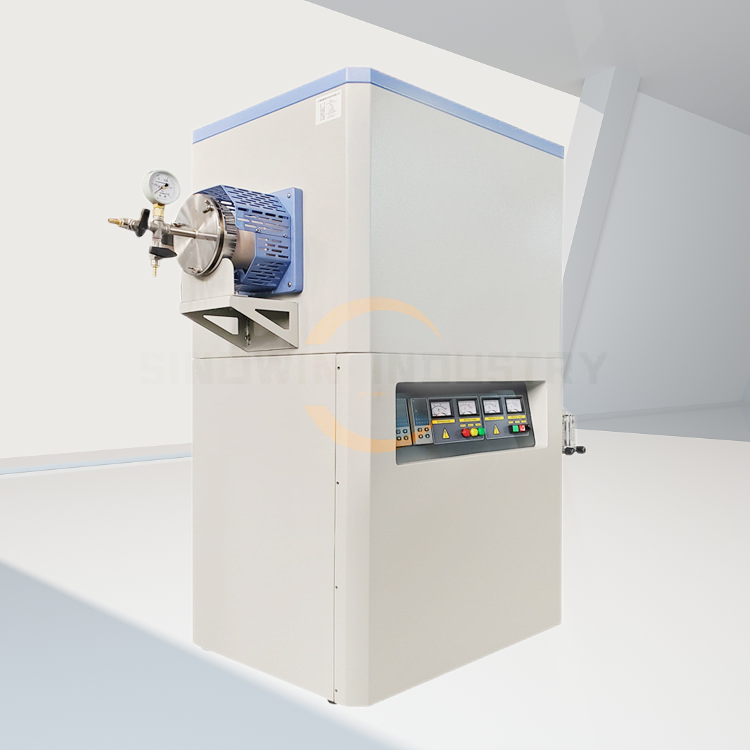

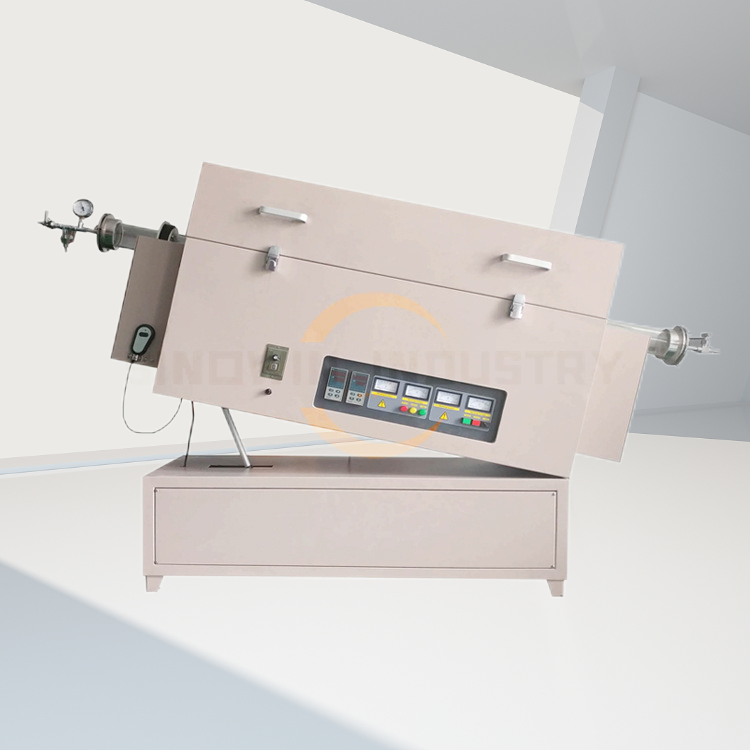

The Sinowin Industry High-Temperature Vacuum Tube Furnace is specifically designed for advanced materials processing. Engineered with a high-purity quartz tube or high-purity alumina tube, this furnace operates within an impressive temperature range of 300℃ to 1600℃.

Our high-temperature vacuum tube furnace features a world-class control system, ensuring exceptional safety, reliability, and user-friendliness. With high-temperature precision control and excellent thermal insulation, the equipment guarantees uniform temperature distribution within the chamber. It is ideal for institutions of higher education, research institutes, and industrial enterprises engaged in high-temperature sintering experiments, quality testing, and small-batch production of metallic materials.

Advantage of High Temperature Vacuum Tube Furnace:

- Versatile High-Temperature Range The High-Temperature Vacuum Tube Furnace operates efficiently within a temperature range of 300℃ to 1600℃, making it ideal for various high-temperature applications, including metal material sintering and quality testing.

- Advanced Control System Equipped with a state-of-the-art 51-segment programmable automatic control system, this vacuum tube furnace ensures high precision in temperature control (±1℃), enhancing reliability for both research and industrial processes.

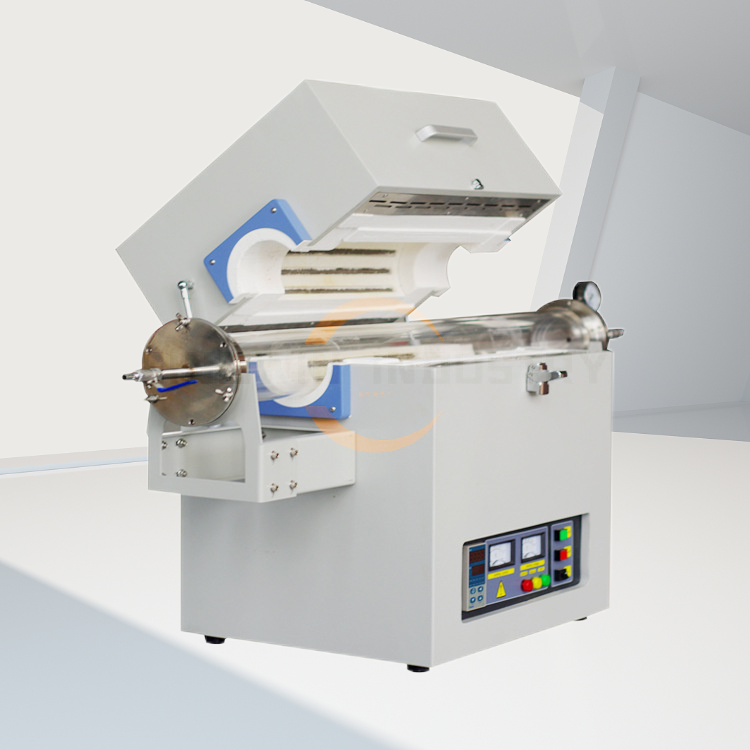

- Robust Construction for Longevity The furnace features high-purity quartz or alumina pipes and a double-layer wind-cooling structure, enabling a furnace shell temperature of below 50℃ and extending the lifespan of the tube while minimizing heat loss.

- Comprehensive Safety Features Our High-Temperature Vacuum Tube Furnace includes built-in over-temperature and electrical leakage protection, ensuring safe operation by automatically cutting off power if temperature limits are exceeded or if a fault is detected.

- Customized Accessories & After-Sales Support Standard components include vacuum pumps and sealing flanges, while optional enhancements such as molecular pump systems and touch screen controls are available. We also provide reliable after-sales service to assist with installation and maintenance.

Parameters of High-Temperature Vacuum Tube Furnace:

Technical parameter of the 1600 vacuum tube furnace:

| Technical parameter of the 1600 vacuum tube furnace | |

| maximum working temperature | 1600℃ (<2 hours) |

| Temperature meter | ● Artificial intelligence PID instrument, automatic temperature control. Two-way anti-parallel silicon voltage regulation, accurately controls the temperature of electric furnace, and has the function of current limit. Prevent power supply voltage instability, current suddenly cause tripping, burn electrical components, etc.

● 51 section programming curve, according to the automatic heating, heat insulation, cooling of the preset program. One key to complete, without workers on duty. ● Built-in temperature control parameter self-setting function.. ● With over-temperature alarm, Thermocouples break alarm, and automatically cut off the power supply, to provide reliable protection. |

| Temperature control accuracy | ±1℃ |

| heating rate | From 0-20℃ / min |

| Thermocouples | Type B (double platinum rhodium), Thermocouples protective tube is 99.7% purity |

| heating element | High purity silicon molybdenum bar |

| Ordinary vacuum | -0.08MPa |

| high vacuum | 710 ^ (-5) Pa (Molecular Pump) |

| Fire-pot | Three layers of full fiber furnace lining, constitute the whole furnace

● The first layer: type 1800 poly-crystalline alumina ceramic fiber. Ensure the furnace enough strength, and ensure excellent heat insulation effect. ● Second layer: type 1430 poly-crystalline alumina ceramic fiber. ● The third layer: several thermal insulation cotton. |

| Furnace structure | ● High strength carbon steel made, pickling phosphorus and rust removal, electrostatic plastic, beautiful and generous.

● Double-layer air-cooled furnace shell, built-in 2-4 scattered heat fans, to ensure that the furnace shell surface temperature is lower than 60℃. |

| Product warranty | 1. From the date of acceptance, the high temperature box furnace is free warranty for one year. If the equipment is wrong, repair it on site, and provide technical support for life!

2. After exceeding the warranty period, the cost price to provide the accessories. |

Size of the 1200℃ Vacuum Tube Furnace

| Chamber Size

(Dia.*Length of heating zone) |

Power | Temperature | thermocouple | furnace tube | Heating elements |

| 40x300mm | 3 KW | 1200℃ | K type | quartz tube | resistance wire |

| 60x300mm | 3 KW | ||||

| 80x300mm | 5 KW | ||||

| 100x300mm | 5 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 3 KW | ||||

| 60x450mm | 3 KW | ||||

| 80x450mm | 5 KW | ||||

| 100x450mm | 5 KW | ||||

| 120x450mm | 6 KW |

Size of the 1400℃ Vacuum Tube Furnace

| Chamber Size

(Dia.*Length of heating zone) |

Power | Temperature | thermocouple | furnace tube | Heating elements |

| 40x300mm | 4 KW | 1400℃ | S type | Alumina tube | Sic Heater |

| 60x300mm | 4 KW | ||||

| 80x300mm | 4 KW | ||||

| 100x300mm | 6 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 4 KW | ||||

| 60x450mm | 4 KW | ||||

| 80x450mm | 4 KW | ||||

| 100x450mm | 6 KW | ||||

| 120x450mm | 6 KW |

Size of the 1600℃ Vacuum Tube Furnace

| Chamber Size

(Dia.*Length of heating zone) |

Power | Temperature | thermocouple | furnace tube | Heating elements |

| 40x300mm | 4 KW | 1600℃ | B type | Alumina tube | Mosi2 |

| 60x300mm | 4 KW | ||||

| 80x300mm | 4 KW | ||||

| 100x300mm | 6 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 5 KW | ||||

| 60x450mm | 5 KW | ||||

| 80x450mm | 5 KW | ||||

| 100x450mm | 7 KW | ||||

| 120x450mm | 7 KW |

Key Features of the High-Temperature Vacuum Tube Furnace:

- Maximum Temperature Capacities:

– 1200℃ with HRE resistance wire heating

– 1400℃ with silicon carbide rod heating

– 1600℃ with silicon molybdenum rod heating

- Smart 51-segment programmable automatic control system

- Dual-layer air-cooling structure; outer shell temperature remains under 50℃

- 304 stainless steel double-layer sealed flange

- Adjustable flange support structure at both ends, significantly extending the life of the furnace tube

- Over-temperature protection feature that automatically cuts power when the temperature exceeds the preset limit

- Electrical safety protection with automatic power cutoff in case of leakage

- Heating rate of ≤ 20℃/min

- Temperature control precision of ±1℃

- Maximum vacuum degree of -0.08MPa

- Equipped with a molecular pump unit, achieving a vacuum level of 7×10^(-5) Pa

Whether you’re in the manufacturing sector or a research facility, our High-Temperature Vacuum Tube Furnace is an indispensable furnace and one guaranteed option for your heating treatment industry . Experience unparalleled performance and reliability with Sinowin Industry High-Temperature Vacuum Tube Furnace, the ideal solution for your high-temperature processing needs. Order now and elevate your research and production capabilities!

Parameters of High-Temperature Vacuum Tube Furnace:

Technical parameter of the 1600 vacuum tube furnace:

| Technical parameter of the 1600 vacuum tube furnace | |

| maximum working temperature | 1600℃ (<2 hours) |

| Temperature meter | ● Artificial intelligence PID instrument, automatic temperature control. Two-way anti-parallel silicon voltage regulation, accurately controls the temperature of electric furnace, and has the function of current limit. Prevent power supply voltage instability, current suddenly cause tripping, burn electrical components, etc.

● 51 section programming curve, according to the automatic heating, heat insulation, cooling of the preset program. One key to complete, without workers on duty. ● Built-in temperature control parameter self-setting function.. ● With over-temperature alarm, Thermocouples break alarm, and automatically cut off the power supply, to provide reliable protection. |

| Temperature control accuracy | ±1℃ |

| heating rate | From 0-20℃ / min |

| Thermocouples | Type B (double platinum rhodium), Thermocouples protective tube is 99.7% purity |

| heating element | High purity silicon molybdenum bar |

| Ordinary vacuum | -0.08MPa |

| high vacuum | 710 ^ (-5) Pa (Molecular Pump) |

| Fire-pot | Three layers of full fiber furnace lining, constitute the whole furnace

● The first layer: type 1800 poly-crystalline alumina ceramic fiber. Ensure the furnace enough strength, and ensure excellent heat insulation effect. ● Second layer: type 1430 poly-crystalline alumina ceramic fiber. ● The third layer: several thermal insulation cotton. |

| Furnace structure | ● High strength carbon steel made, pickling phosphorus and rust removal, electrostatic plastic, beautiful and generous.

● Double-layer air-cooled furnace shell, built-in 2-4 scattered heat fans, to ensure that the furnace shell surface temperature is lower than 60℃. |

| Product warranty | 1. From the date of acceptance, the high temperature box furnace is free warranty for one year. If the equipment is wrong, repair it on site, and provide technical support for life!

2. After exceeding the warranty period, the cost price to provide the accessories. |

Size of the 1200℃ Vacuum Tube Furnace

| Chamber Size

(Dia.*Length of heating zone) |

Power | Temperature | thermocouple | furnace tube | Heating elements |

| 40x300mm | 3 KW | 1200℃ | K type | quartz tube | resistance wire |

| 60x300mm | 3 KW | ||||

| 80x300mm | 5 KW | ||||

| 100x300mm | 5 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 3 KW | ||||

| 60x450mm | 3 KW | ||||

| 80x450mm | 5 KW | ||||

| 100x450mm | 5 KW | ||||

| 120x450mm | 6 KW |

Size of the 1400℃ Vacuum Tube Furnace

| Chamber Size

(Dia.*Length of heating zone) |

Power | Temperature | thermocouple | furnace tube | Heating elements |

| 40x300mm | 4 KW | 1400℃ | S type | Alumina tube | Sic Heater |

| 60x300mm | 4 KW | ||||

| 80x300mm | 4 KW | ||||

| 100x300mm | 6 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 4 KW | ||||

| 60x450mm | 4 KW | ||||

| 80x450mm | 4 KW | ||||

| 100x450mm | 6 KW | ||||

| 120x450mm | 6 KW |

Size of the 1600℃ Vacuum Tube Furnace

| Chamber Size

(Dia.*Length of heating zone) |

Power | Temperature | thermocouple | furnace tube | Heating elements |

| 40x300mm | 4 KW | 1600℃ | B type | Alumina tube | Mosi2 |

| 60x300mm | 4 KW | ||||

| 80x300mm | 4 KW | ||||

| 100x300mm | 6 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 5 KW | ||||

| 60x450mm | 5 KW | ||||

| 80x450mm | 5 KW | ||||

| 100x450mm | 7 KW | ||||

| 120x450mm | 7 KW |

Q1: What is the maximum operating temperature of the Sinowin high-temperature vacuum tube furnace?

A1: The Sinowin high-temperature vacuum tube furnace can operate at different maximum temperatures depending on the heating element used. With resistance wire heating, the maximum temperature is 1200℃. For silicon carbide rod heating, it can reach up to 1400℃, and when using silicon molybdenum rods, the furnace can achieve a maximum temperature of 1600℃. Choose the heating option that best meets your specific application needs.

Q2: How does the temperature control work in this furnace?

A2: The Sinowin high-temperature vacuum tube furnace features an advanced programmable control system with 51 segments, allowing for highly automated and precise temperature management. The temperature control accuracy is within ±1℃, ensuring consistent and reliable performance for various applications. This intelligent control allows users to set specific heating profiles tailored to their requirements.

Q3: What safety features are included with the furnace?

A3: Safety is a priority with the Sinowin high-temperature vacuum tube furnace. It includes an over-temperature protection feature that automatically disconnects power if the temperature exceeds the set limits. Additionally, the furnace is equipped with a safety mechanism that automatically cuts power in case of a leakage, ensuring user protection during operation. These features are designed to operate reliably in demanding environments.

Q4: What is the cooling system like for this furnace?

A4: The Sinowin furnace utilizes a double-layer air-cooling structure to effectively manage external temperatures. The surface temperature of the furnace shell remains below 50℃, which enhances safety and reduces the risk of burns when handling the equipment. This thoughtful design ensures that the furnace can be operated in various settings without compromising the safety of users or the equipment itself.

Q5: Can this furnace achieve a high vacuum level?

A5: Yes, the Sinowin high-temperature vacuum tube furnace is capable of reaching an impressive maximum vacuum level of -0.08MPa, with a capability to attain a vacuum of 7×10^(-5)Pa when equipped with a molecular pump unit. This high vacuum performance makes it ideal for advanced material processing and experimental applications where controlled environments are crucial.

Q6: What is the heating rate for this furnace?

A6: The Sinowin high-temperature vacuum tube furnace has a heating rate that does not exceed 20℃ per minute. This controlled heating rate allows for safe and effective thermal treatment of materials, minimizing the risk of thermal shock and ensuring even heating throughout the material being processed.

Q7: What materials are the furnace tubes made from?

A7: The furnace tubes of the Sinowin high-temperature vacuum tube furnace are constructed from high-purity quartz or high-purity alumina, depending on your selection. Both materials are designed to withstand high temperatures and offer excellent thermal insulation, ensuring optimal performance and longevity under rigorous operating conditions.