Product Description:

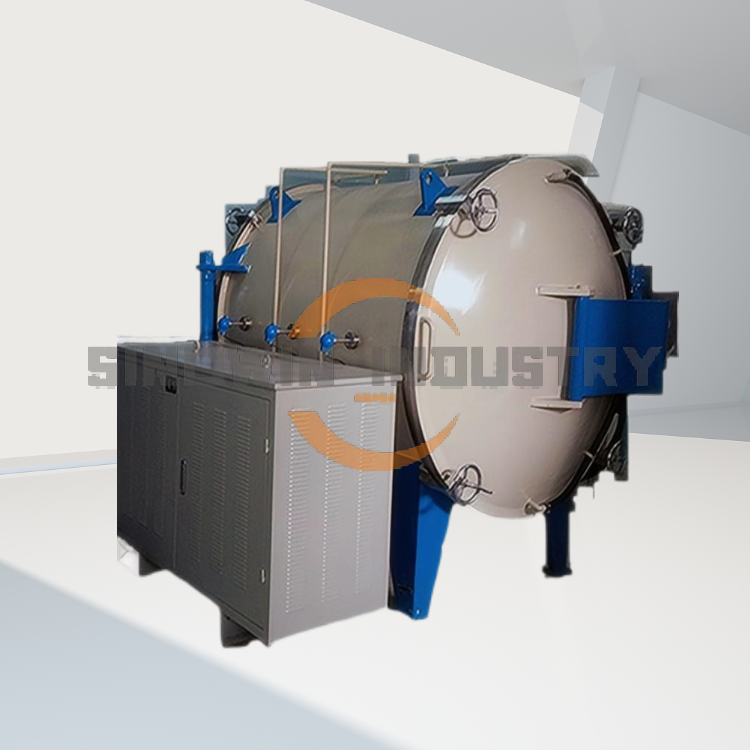

The Vertical Graphitization Furnace with Bottom Discharge, is designed specifically for the high-efficiency purification of graphite powder, needle coke, carbon nanotubes, and the graphitization of high-purity, high-crystallinity carbon whiskers. This advanced furnace is an essential tool for the sintering and graphitization of carbon fiber filaments and various other materials that can be sintered and melted in a carbon environment.

Application Range:

The Vertical Graphitization Furnace is ideal for large-scale graphite purification processes. Operating at temperatures up to 3000℃, with an optimal working temperature of 2800℃, this furnace efficiently achieves the sophisticated graphitization tasks required in modern material processing.

Key Performance Features:

- Vertical Structure with Bottom Discharge: This furnace boasts a vertical design that facilitates efficient discharging of processed materials, enhancing operational convenience.

- High Temperature Resistance: Capable of reaching a stunning maximum temperature of 3000℃, the furnace is engineered to handle demanding graphitization processes.

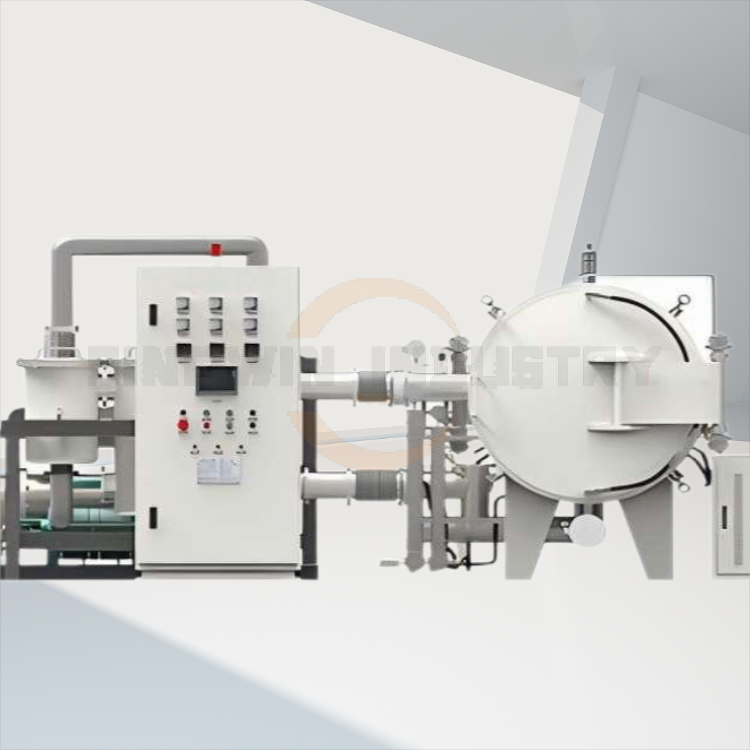

- Superior Sealing and Purity: The furnace features a fully sealed structure, including a vacuum pumping system and an argon gas replacement system, ensuring the integrity and purity of the gases within the furnace.

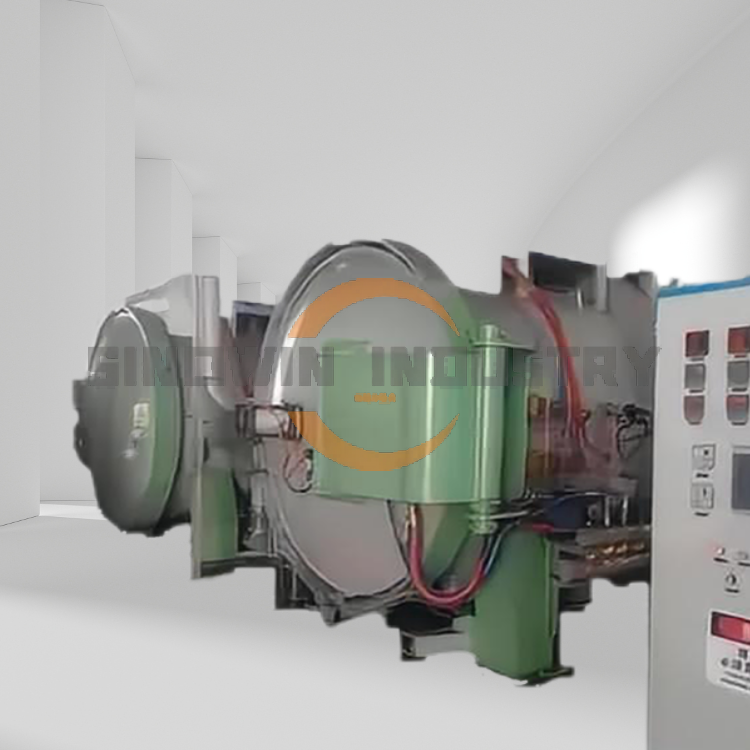

- Energy Efficient Design: Utilizing electromagnetic induction heating technology, the system directly heats the graphite boat, resulting in high thermal efficiency and substantial energy savings.

- Rapid Heating Rate: The furnace can achieve heating rates of up to 600℃/h (with faster rates achievable at lower temperatures), streamlining the graphitization process.

- Precision Temperature Control: A special infrared temperature measurement technology, combined with PID segmented control of the heating curve, ensures precise temperature regulation with minimal error.

- Enhanced Safety Measures: Constructed with a double-layer stainless steel shell and a water-cooled interlayer, the external shell temperature remains below 50℃, ensuring safe operation. The system is equipped with pressure, water, and temperature alarms, along with an overpressure relief mechanism.

Optional Features:

- High Vacuum System: The vacuum system consists of a vacuum pump, Roots pump, diffusion pump, molecular pump, slide valve pump, and gate valve, customized based on user vacuum requirements. Hunan Apide provides expert selection services.

- Gas Purification System

- Closed-loop Cooling Water System

- Silicon-controlled Rectifier Power Supply / IGBT Power Supply

In summary, the Vertical Graphitization Furnace with Bottom Discharge is a robust, energy-efficient solution tailored for high-performance materials processing, ensuring safety, precision, and purity throughout the graphitization process. Upgrade your operations with this cutting-edge furnace today!

Technical Parameter:

| Work Size (mm) | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Volume(L) | 9 | 28 | 125 | 196 | 282 | 452 |

| Heating Power | 100 KW | 160 KW | 200 KW | 250 KW | 300 KW | 350 KW |

| Frequency | 2000 Hz | 2000 Hz | 2000 Hz | 1500 Hz | 1500 Hz | 1500 Hz |

| Max.Temperature | 3050°C | |||||

| Ultra Vacuum | 1.2×10-3 mbar | |||||

| Optional High Vacuum | 5×10-5 mbar | |||||

| Max.temperature rise rate | 15°C/min (RT1500°C), 10°C/min (1500°C2500°C), 5°C/min (2500°C~3000°C) | |||||

| Vacuum Pressure | 6.7×10-3 mbar/hr | |||||

| Atmosphere | High Vacuum(optional)/ Vacuum/ Inert Gas(Ar or N2)

Vacuum and high vacuum atmospheres are only allowed below 2200°C |

|||||

| Power | 3P, 380V, 50Hz/60Hz | |||||

| Pressure of the cooling water | 1.5~2.5 bar | |||||

| Water of the cooling water | ≤28 °C | |||||

Customizable size according to your heat treatment requirement for the bottom discharge vertifcal Graphitization furnace,for example the bigger size :

Φ8001600mm.Φ10002000mm.Φ1200*2500mm. Whether you are in research, analysis, or manufacturing, the bottom discharge vertifcal Graphitization furnace supplied from SINOWIN INDUSTRY is your best choice.

Donot hesitate to Contact us today for a quote and transform your scientific journey completely.

Q&A for Vertical Graphitization Furnace with Bottom Discharge

Q1: What are the main features of the Vertical Graphitization Furnace?

A1: The Vertical Graphitization Furnace boasts a robust vertical structure with bottom discharge, featuring a dual-layer water cooling design. The inner chamber is constructed from 304 stainless steel, ensuring durability and efficiency. It supports both vacuum operation and the introduction of protective gases, making it versatile for various applications, particularly in purifying graphite, with operating temperatures reaching up to 3000°C and a maximum sustained working temperature of 2800°C.

Q2: How energy-efficient is this furnace compared to traditional models?

A2: This furnace is designed with energy efficiency in mind. Utilizing electromagnetic induction heating, it directly heats the graphite boats, resulting in significantly higher thermal efficiency and reduced power consumption compared to conventional heating methods. This makes it an eco-friendly and cost-effective choice for long-term operations.

Q3: Can the furnace handle high-temperature operations safely?

A3: Absolutely. The Vertical Graphitization Furnace features a fully sealed structure with an integrated vacuum extraction system and argon gas replacement system, ensuring the highest purity of the atmosphere within the chamber during operations. This full containment provides optimal safety and efficiency even at high temperatures, significantly reducing risks of contamination.

Q4: What is the temperature control technology used in this furnace?

A4: The furnace incorporates advanced infrared temperature measurement technology along with a PID (Proportional-Integral-Derivative) segmented program control for the temperature rise curve. This precision control allows for strict monitoring and minimal deviation, ensuring consistent performance throughout the heating process.

Q5: What is the maximum heating rate of the furnace, and is it effective for low-temperature applications?

A5: The furnace can achieve an impressive heating rate of up to 600°C per hour, making it suitable for quick thermal processing. It is also capable of efficient low-temperature heating, allowing for versatile applications across various stages of material treatment.

| Work Size (mm) | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Volume(L) | 9 | 28 | 125 | 196 | 282 | 452 |

| Heating Power | 100 KW | 160 KW | 200 KW | 250 KW | 300 KW | 350 KW |

| Frequency | 2000 Hz | 2000 Hz | 2000 Hz | 1500 Hz | 1500 Hz | 1500 Hz |

| Max.Temperature | 3050°C | |||||

| Ultra Vacuum | 1.2×10-3 mbar | |||||

| Optional High Vacuum | 5×10-5 mbar | |||||

| Max.temperature rise rate | 15°C/min (RT1500°C), 10°C/min (1500°C2500°C), 5°C/min (2500°C~3000°C) | |||||

| Vacuum Pressure | 6.7×10-3 mbar/hr | |||||

| Atmosphere | High Vacuum(optional)/ Vacuum/ Inert Gas(Ar or N2)

Vacuum and high vacuum atmospheres are only allowed below 2200°C |

|||||

| Power | 3P, 380V, 50Hz/60Hz | |||||

| Pressure of the cooling water | 1.5~2.5 bar | |||||

| Water of the cooling water | ≤28 °C | |||||