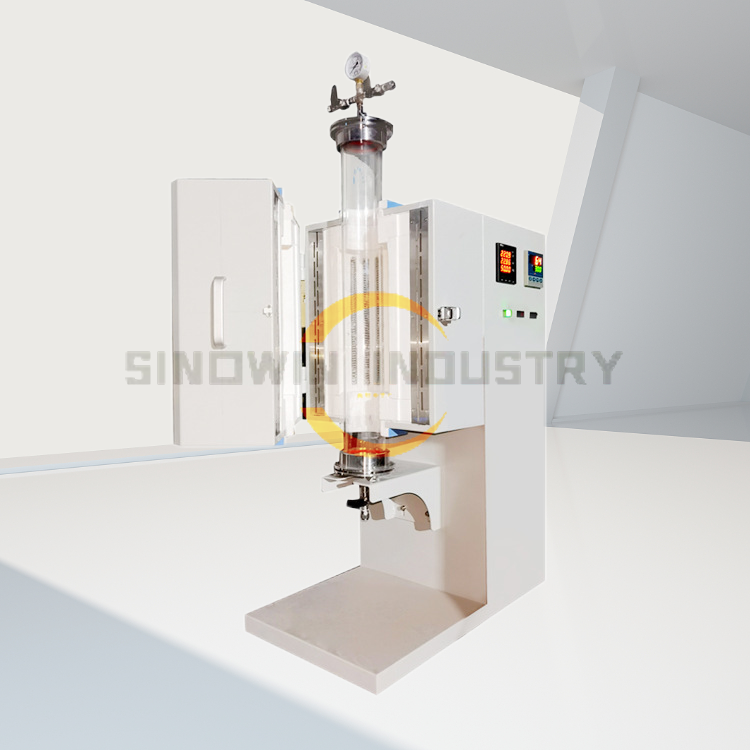

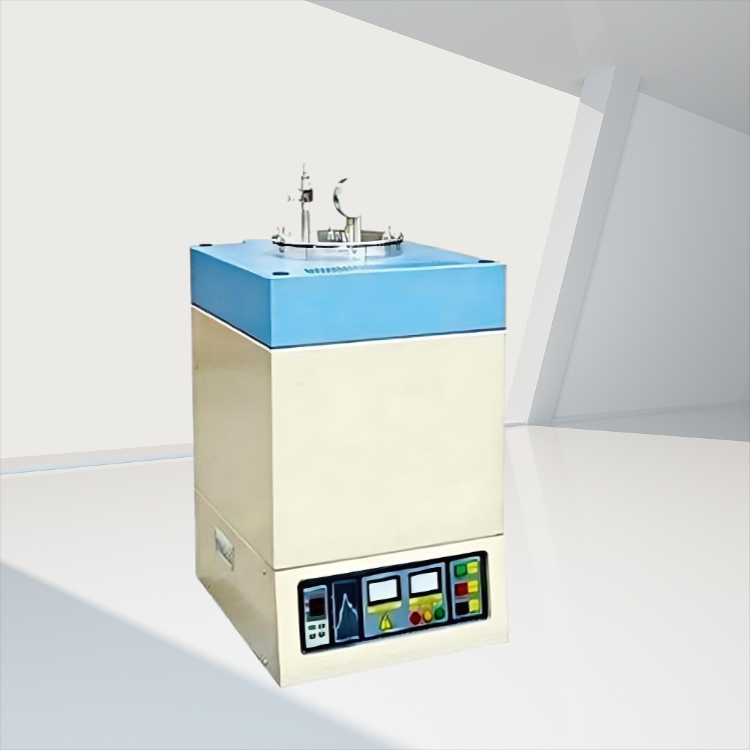

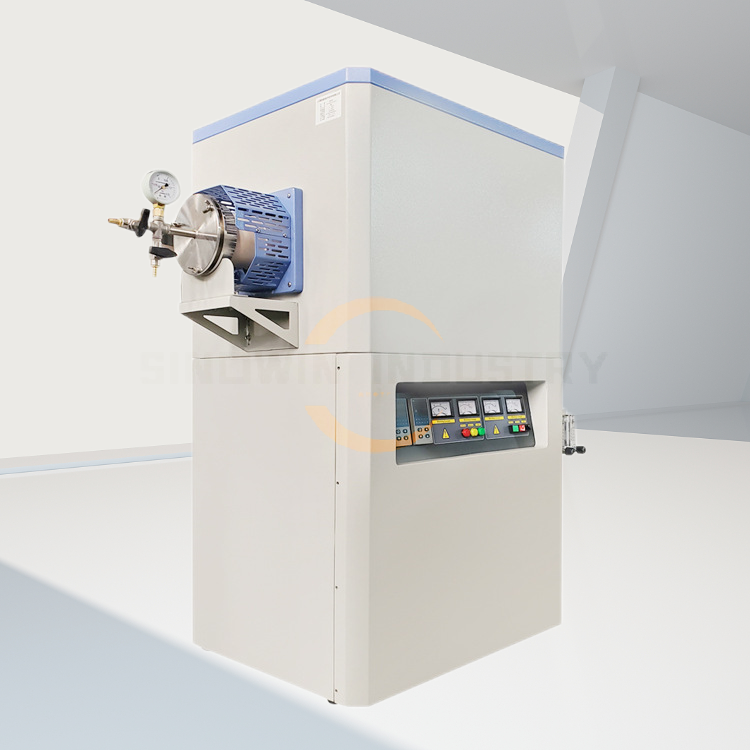

Product Description:

The Vertical Tube Furnace is a highly efficient and stable material processing equipment designed to handle a variety of temperature ranges, with the choice of high-purity quartz or high-purity alumina material for the furnace tube, ensuring optimal high-temperature performance and stability by Sinowin furnace for a wide range of applications, particularly in vacuum or protective atmosphere environments. Whether it’s for pre-sintering, sintering, coating, or high-temperature pyrolysis and low-temperature deposition processes, this furnace provides an ideal processing environment to meet the demands of both scientific research and industrial production.Equipped with a vacuum sealing flange system, it guarantees excellent sealing and high-efficiency performance during operation.

Key Features:

● Temperature Range:

This furnace can achieve temperatures up to 1200℃ with HRE resistance wire heating, 1400℃ with silicon carbide rod heating, and an impressive 1600℃ with silicon molybdenum rods.

● Intelligent Control:

The furnace is fitted with a 50-segment programmable automatic control system, allowing for flexible and variable temperature programming to accommodate a wide array of complex experimental requirements.

● Cooling Design:

Featuring a double-layer air-cooled structure, the furnace shell ensures stable performance during prolonged operation, enhancing the longevity of the equipment.

● Durability:

Constructed with stainless steel double-layer sealing flanges, this furnace offers superior sealing and durability, suitable for intensive usage.

● Safety Assurance:

With an over-temperature protection feature, the furnace automatically cuts power if temperatures exceed preset safety limits or leakage values, ensuring the safety of the operator.

● Temperature Control:

The heating rate is capped at 20℃ per minute, with a temperature control accuracy of ±1℃, ensuring precise experimental results.

● High Vacuum Performance:

Achieving a maximum vacuum level of -0.1MPa, the furnace can reach a vacuum level of up to 7×10^-4Pa when configured with a molecular pump unit.

Standard Accessories:

- 4 Tube Plugs

- 1 Thermocouple

- 1 Furnace Tube

- 1 Vacuum Pump

- 1 Set of Vacuum Flanges

- 1 Vacuum Pressure Gauge

The Vertical Tube Furnace is an indispensable tool for researchers and industrial manufacturers alike, combining advanced technology with robust construction to deliver exceptional results in material processing.

Whether you are in research, analysis, or manufacturing, the vertical Tube Furnace supplied from SINOWIN INDUSTRY is one guaranteed option for your industry.Donot hesitate to Contact us at once for any further information of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the thermal treatment .

Technical Parameter of the vertical tube furnace:

1600℃ vertical tube furnace details:

| 1600℃ vertical tube furnace details | |

| Max.temperature | 1600℃ (<2hrs) |

| Temperature instrument | ● Artificial intelligence PID instrument, automatic temperature control. Two-way inverse parallel thyristor voltage regulation, the electric furnace temperature is accurately controlled, and has the current limiting function. Prevent power supply voltage instability, sudden excessive current caused tripping, burning electrical components and so on.

● 51 programming curve, according to the preset program automatic heating, heat preservation, cooling. One click to complete, no worker on duty. ● Built-in automatic temperature control parameter self-tuning function. ● Features over-temperature alarm, thermocouple breakage alarm, and automatically cuts off the power supply, providing reliable protection.

|

| Temperature control accuracy | ±1℃ |

| Heating rate | 0-20℃/miniute |

| Thermoelectric couple | Type B (double platinum rhodium), the thermocouple protection tube is 99.7% pure corundum tube

|

| Heating element | High purity silicon molybdenum rod(MoSic) |

| Ordinary vacuum | -0.08MPa |

| High vacuum | 7×10^(-3)Pa molecular pump |

| furnace chamber | Three layers of all-fiber lining constitute the entire furnace

● The first layer: type 1800 polycrystalline alumina ceramic fiber. To ensure sufficient strength of the furnace, but also to ensure excellent thermal insulation effect. ● The second layer: 1430 polycrystalline alumina ceramic fiber. ● Third layer: thermal insulation cotton |

| Furnace shell structure | ● Made of high-strength carbon steel, after pickling, phosphating and rust removal, electrostatic spray, beautiful and generous.

● Double-layer air-cooled furnace shell with built-in 2-4 cooling fans to ensure that the surface temperature of the furnace shell is below 60℃. |

| Product warranty | ● From the date of self-acceptance, the entire high-temperature box furnace is free of charge for one year warranty. If problems arise with the equipment, on-site repairs will be conducted, and lifelong technical support will be provided!

● After the warranty period expires, spare parts will be provided at cost price. |

Size of the1200℃ vertical tube furnace

| Chamber size

(Diameter x length of heating zone) |

Power | Max.temperature | Thermoelectric couple | furnace tube | heating element |

| 40x300mm | 3 KW | 1200℃ | K type | Quartz tube | Resistance wire |

| 60x300mm | 3 KW | ||||

| 80x300mm | 5 KW | ||||

| 100x300mm | 5 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 3 KW | ||||

| 60x450mm | 3 KW | ||||

| 80x450mm | 5 KW | ||||

| 100x450mm | 5 KW | ||||

| 120x450mm | 6 KW |

Size of the1400℃ vertical tube furnace

| Chamber size

(Diameter x length of heating zone) |

Power | Max.temperature | Thermoelectric couple | furnace tube | heating element |

| 40x300mm | 4 KW | 1400℃ | S type | Alumina tube | Sic |

| 60x300mm | 4 KW | ||||

| 80x300mm | 4 KW | ||||

| 100x300mm | 6 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 4 KW | ||||

| 60x450mm | 4 KW | ||||

| 80x450mm | 4 KW | ||||

| 100x450mm | 6 KW | ||||

| 120x450mm | 6 KW |

Size of the1600℃ vertical tube furnace

| Chamber size

(Diameter x length of heating zone) |

Power | Max.temperature | Thermoelectric couple | furnace tube | heating element |

| 40x300mm | 4 KW | 1600℃ | B type | Alumina tube | MoSi2 |

| 60x300mm | 4 KW | ||||

| 80x300mm | 4 KW | ||||

| 100x300mm | 6 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 5 KW | ||||

| 60x450mm | 5 KW | ||||

| 80x450mm | 5 KW | ||||

| 100x450mm | 7 KW | ||||

| 120x450mm | 7 KW |

Please feel free to consult for any additional questions or specifics related to your requirements for the vertical tube furnace.

Size of the1200℃ vertical tube furnace

| Chamber size

(Diameter x length of heating zone) |

Power | Max.temperature | Thermoelectric couple | furnace tube | heating element |

| 40x300mm | 3 KW | 1200℃ | K type | Quartz tube | Resistance wire |

| 60x300mm | 3 KW | ||||

| 80x300mm | 5 KW | ||||

| 100x300mm | 5 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 3 KW | ||||

| 60x450mm | 3 KW | ||||

| 80x450mm | 5 KW | ||||

| 100x450mm | 5 KW | ||||

| 120x450mm | 6 KW |

Size of the1400℃ vertical tube furnace

| Chamber size

(Diameter x length of heating zone) |

Power | Max.temperature | Thermoelectric couple | furnace tube | heating element |

| 40x300mm | 4 KW | 1400℃ | S type | Alumina tube | Sic |

| 60x300mm | 4 KW | ||||

| 80x300mm | 4 KW | ||||

| 100x300mm | 6 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 4 KW | ||||

| 60x450mm | 4 KW | ||||

| 80x450mm | 4 KW | ||||

| 100x450mm | 6 KW | ||||

| 120x450mm | 6 KW |

Size of the1600℃ vertical tube furnace

| Chamber size

(Diameter x length of heating zone) |

Power | Max.temperature | Thermoelectric couple | furnace tube | heating element |

| 40x300mm | 4 KW | 1600℃ | B type | Alumina tube | MoSi2 |

| 60x300mm | 4 KW | ||||

| 80x300mm | 4 KW | ||||

| 100x300mm | 6 KW | ||||

| 120x300mm | 6 KW | ||||

| 40x450mm | 5 KW | ||||

| 60x450mm | 5 KW | ||||

| 80x450mm | 5 KW | ||||

| 100x450mm | 7 KW | ||||

| 120x450mm | 7 KW |

Q1: What is the maximum temperature this vertical tube furnace can reach?

A1: The vertical tube furnace is designed with multiple heating options to accommodate various temperature needs. With HRE resistance wire, it can reach up to 1200°C. If you are using silicon carbide rods, the temperature can go as high as 1400°C, while with silicon molybdenum rods, you can achieve an impressive maximum temperature of 1600°C. This versatility makes it ideal for complex experimental applications.

Q2: How does the programmable control system work?

A2: The furnace features a 50-segment programmable automatic control system. This advanced feature allows for highly flexible temperature programming, enabling you to customize the heating and cooling profiles according to the specific requirements of your experiments. This capability is particularly useful for complex thermal processes, ensuring precise control throughout your procedures.

Q3: What safety features does this furnace offer?

A3: Safety is a top priority with our vertical tube furnace. It comes equipped with an over-temperature protection function, which automatically cuts off power if the temperature exceeds the set limits or if a leak is detected. This ensures the safety of the operator and the integrity of the equipment during operation, giving you peace of mind as you conduct your experiments.

Q4: How durable is the construction of this furnace?

A4: This vertical tube furnace is built to last, featuring a robust dual-layer stainless steel flanged design that significantly enhances its durability and sealing capabilities. The double-layer cooling design not only guarantees stable performance during prolonged use but also contributes to the longevity of the device, making it a worthwhile investment for your laboratory needs.

Q5: What kind of vacuum performance can I expect?

A5: The furnace boasts impressive vacuum performance, with a maximum vacuum level of -0.1 MPa. This high vacuum capability is invaluable for ensuring optimal conditions for your thermal processes, particularly in experiments that require a controlled environment. It allows for high-quality results, especially in sensitive applications.

Q6: What is the temperature control accuracy of the furnace?

A6: The vertical tube furnace is equipped with precise temperature control, featuring a heating rate of ≦20°C per minute and a temperature control accuracy of ±1°C. This level of precision is crucial for achieving repeatable and reliable experimental outcomes, making this furnace an excellent choice for rigorous scientific research.

Donot hesitate to Contact us at once for any further information of Sinowin Industry’s industrial&lab furnaces , and we are not only a supplier but a reliable partner to assist you the safe solutions of the thermal treatment .